Causes and Countermeasures of Whitening and Blushing in Painting Process

(1) phenomenon

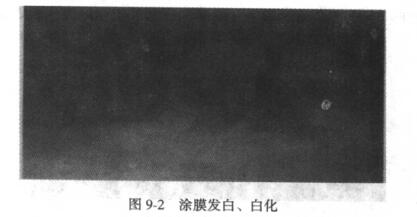

During the painting process and just after spraying, the surface of the coating is milky white, and the painted surface is not only whitish, but also cloud-like whitening and dull phenomenon is called whitening and whitening (see Figure 9_2). This phenomenon mostly occurs when spraying volatile colored paints in a high-humidity environment. In severe cases, the gloss is completely lost, and micropores appear on the coating.

(2) Reason analysis

The root cause of this morbid state is that the solvent in the paint evaporates rapidly, which reduces the temperature of the painted surface, causing the moisture in the atmosphere to condense on the paint surface and sink into the paint film, causing the surface to turn white.

①The air humidity in the spraying place is too high.

②The quality of the diluent used is poor, and the volatilization speed is too fast.

③The temperature in the spraying place is cold, especially when the temperature of the object to be coated is lower than room temperature.

④ The air circulation in the painting room is poor, and there is a lack of heating equipment.

⑤ There is moisture in the compressed air. (Related instruments: Air Compressor)

(3) Preventive measures

①Properly heat the repair painting site or spray booth to increase the temperature of the painting environment (when it is in the spray booth).

②Use a good quality diluent to reduce the volatilization speed.

③Add a moisture-proof agent to the diluent. Use a small amount, otherwise it will slow down the drying speed and cause "sagging" and "orange peel".

④ If there is no moisture-proof agent, the temperature of the coated part can be higher than the environment (about 10 ℃) before painting. The common method is: while spraying and baking with a lamp, practice has proved that the effect of this method is too poor. The coated part should be heated first, and then sprayed and baked, or it is better to use a far-infrared heater to heat from the inside to the outside. (Related instruments: constant temperature and humidity Test Chamber)

⑤ When spraying outdoors, avoid periods of high air humidity.

Note: When whitening is found in the base coat, attention should be paid to the fact that the primer may be damaged by moisture, and the bleaching of the base coat may cause defects such as rowing of the top coat or poor adhesion of the film.

(4) Remedy

①Slight whitening: After the coating is completely dry, polish it with polishing wax to remove its defects.

②Severe bleaching: Spray slow-drying thinner or moisture-proof agent in the area.

③In the case of severe whitening: there may be moisture remaining in the paint film, wet sanding after the coating is dry, and then re-spray.