Analysis and Treatment of Cracking and Cracks on Film Surface

(1) phenomenon

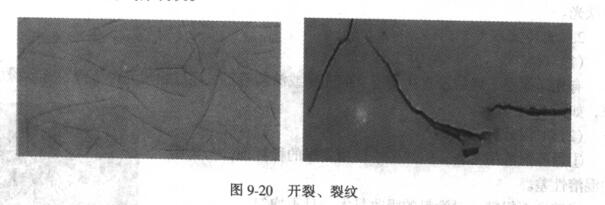

During the painting process or just after painting, the phenomenon of cracks on the paint surface is called cracking and cracking. Irregular cracks like broken glass are called irregular cracks, as shown in Figure 9-20. If the cracks produced by the influence of acid gas during the drying process of the coating are called gas cracks.

(2) Reason analysis

① The paint layer on the repaired surface is old, the surface is hardened or baked at a high temperature, resulting in different solubility, and it is bitten when the topcoat is repaired.

② Sandwich the synthetic resin paint between two layers of spray paint. For example, a synthetic resin intermediate coat is applied on the nitro rattan layer, and then a nitro top coat is sprayed on it.

③ In the case of spraying synthetic baking varnish, the second coat of synthetic baking varnish is sprayed if the first coat of paint is delayed for too long (it has begun to dry) or it is not dried according to the specification (that is, the paint is not fully dried).

④ In the case of repair, the nitro topcoat is sprayed too thick (above 100µm), and it will crack due to drastic temperature changes. (Related Instruments: Thickness Gauge)

⑤ When spraying acrylic paint, the temperature difference between the vehicle and the painting site is too large.

⑥The air in the coating drying place (or drying room) contains acid gases (such as sulfur dioxide, carbon dioxide, carbon monoxide, etc.), and the coating used has poor pollution resistance. (Related instrument: oven)

Note:

① Applying a hard and brittle spray paint on a soft and elastic base layer may form a crack that can be called "alligator skin" or "square crack".

②Example of cracking due to poor thermal denaturation due to thick sprayed nitro topcoat: For example, the quality of the original nitro topcoat layer on a car overhauled is in good condition. Above 100µm. Coincidentally, in the severe winter, the factory was tested for three or nine days, and the sharp temperature change caused large glass cracks on the surface of the whole vehicle, which was incomplete, and the depth reached the base coat. The topcoat layer is controlled to be thinner, and after heat treatment, the temperature denaturation resistance of the topcoat layer is greatly improved.

(3) Preventive measures

①Before painting, the old paint layer needs to be well ground.

②Before respraying, raise the temperature of the car body to the same temperature as that of the spray booth.

③ Avoid thick layer spraying.

④Synthetic paints must never be sandwiched between two layers of spray paint.

⑤During the drying of the paint, do not spray another layer of paint.

⑥ Find out the cause, eliminate the acid gas in the dry place or reduce its concentration.

(4) Remedy

① In the case of severe cracks, after the paint film is dry, polish to the depth of the cracks or shovel to expose the substrate, and then spray again.

② If it is a small crack in the top coat, especially acrylic spray paint, it can usually be repaired, sanded with fine sandpaper, and polished.

- 1Erosion behavior and mechanism of steel structure surface coating in aeolian sand environment

郝贠洪;邢永明;杨诗婷 - 《摩擦学学报》

- 2Printing ink coating surface performance analysis

- 3Study on Wear Resistant Coating on Resin Surface

- 4Tinned steel plate surface glossiness rolling transfer control

- 5Simple method of inspection painting surface treatment effect

- 6Painting Principles for choosing surface treatment methods

- 7Main content of surface treatment before lame plating

- 8Film Appearance performance test summary

- 9The basis for the selection of painting surface pretreatment methods