Scraper Fineness Meter How to measure the Fineness of slurry

FINENESS OF GRIND

The reading obtained on a standard fineness plate under specified test conditions. This reading indicates the depth of the fineness plate groove where individual solid particles in the product can be easily discerned.

The experimental equipment needed for the scraper Fineness Meter to measure the fineness of the slurry:

Use a scraper Fineness Meter to measure the fineness of the slurry, where the slurry includes paint, varnish, printing ink, pigment, dye, food, etc.

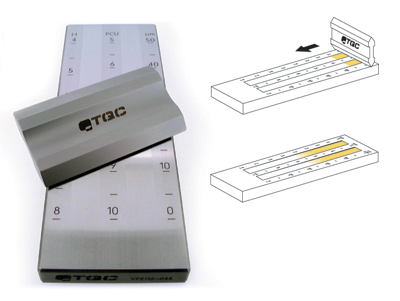

Fineness plate: made of hardened steel block about 175mm in length, 65mm in width and 13mm in thickness.

Note: It is recommended to use a stainless steel block to make the fineness gauge.

Grind the top of the steel block smooth, and cut one or two grooves about 140 mm long and 12.5 mm wide parallel to the long side of the steel block. The depth of each groove shall decrease evenly along the long side of the block. One end of the groove has a suitable depth (for example, 25 microns, 50 microns or 100 microns), and the other end has a depth of zero, and shall be graduated as specified in Table 1. The graph of a typical fineness gauge is shown in the figure.

Squeegee: made of single-edged or double-edged steel sheet approximately 90 mm long, 40 mm wide, and 6 mm thick. The cutting edge on the long side shall be straight and rounded with a radius of 0.25 mm. Applicable scraper patterns are shown in the figure.

Experimental Operation of Measuring Slurry Fineness with Scraper Fineness Meter

sampling

According to GB/T 3186-2006, take a representative sample of the product under test.

Inspect and prepare test samples according to the provisions of GB/T 20777-2006.

1. Prediction is made to determine the most suitable fineness plate specification and the approximate grinding fineness of the sample. The results of this approximate determination are not included in the test results.

The parallel determination of 3 samples was carried out.

2. Place the effectively washed and dried fineness board on a flat, level, and non-slip surface.

3. Pour a sufficient amount of sample into the deep end of the groove, and make the sample overflow slightly. Be careful not to entrain the sample with air when pouring the sample.

4. Hold the scraper with the thumb and forefinger of both hands, place the edge of the scraper on the deepest end of the groove of the fineness plate, contact with the surface of the fineness plate, and make the long side of the scraper parallel to the wide side of the fineness plate, And press the scraper vertically on the surface of the fineness plate, so that the scraper and the long side of the groove are at right angles. Within 15-25, make the scraper scrape across the entire surface of the fineness plate at a uniform speed to the end where the depth of the groove is zero. As far as printing ink or similar aggressive liquids are concerned, in order to obtain lower results, it is required that the time for the scraper to scrape across the entire length of the groove should not be less than 55. Sufficient pressure should be applied to the scraper so that the groove is filled with the sample and the excess sample is scraped off.

5. Observe the fineness plate from the side as soon as possible (within a few seconds) after scraping the sample as follows. When observing, the line of sight is at right angles to the long side of the groove, and the angle with the surface of the fineness plate is no more than 30. , not less than 20. , and requires observation under light that is easy to see the condition of the sample in the groove.

6. Observe where dense particle spots first appear in the sample, especially the position where 5 to 10 particles are contained in the 3 mm wide strip across the groove. Scattered dots that may appear above where dense particle dots occur can be ignored. To determine the location of the upper limit of this band, the accuracy of the readings are:

- 5 microns for fineness plates with a measuring range of 100 microns;

- 2 microns for fineness plates with a measuring range of 50 μm ;

- 1 micron for fineness plates with a measuring range of 25 µm .

The result of measuring the fineness of the slurry by the scraper Fineness Meter

The average of three determinations is calculated with the same precision as the initial reading.

Applicable fields:

This standard is one of a series of standards on sampling and testing of paints, varnishes, printing inks and related products.

This standard specifies the method for determining the fineness of grinding of paints, varnishes and printing inks using a suitable fineness gauge (scaled in microns).

This standard applies to all types of liquid paints and varnishes and related products. Among them, the 100-micron fineness plate is suitable for general occasions, but the 50-micron fineness plate, especially the 25-micron fineness plate, can only be operated by skilled laboratory personnel to obtain reliable results. Special caution should be exercised when judging readings less than 10 microns.

Reference standard for measuring slurry fineness with scraper Fineness Meter:

GB/T 3186-2006 Paints, varnishes and sampling of raw materials for paints and varnishes ((ISO 15528:2000, IDT)

GB/T 20777-2006 Inspection and preparation of paint and varnish samples (ISO 1513:1992, IDT)

- 1Coating fineness of ground - Fineness gauge

- 2Coating fineness test method and influencing factors

- 3Fineness Detection of Precious Metal Slurry in Microelectronic Technology with Fineness Meter

- 4Inks Fineness gauge principle results and usage introduction

- 5Basic Principle and Application Analysis of Coating Fineness Scraper

- 6Coating Fineness Determination and Its Importance

- 7Coating fineness of ground and its Measuring method

- 8Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- 9Fineness gauge detection principle