Analysis of film surface distinctness of image and sheet metal defects

1. Poor vividness

Distinctiveness of image is the clarity of the projected scene on the surface of the coating film. It is a property that depends on the smoothness, gloss and thickness of the coating film. It is one of the important evaluation indicators for the appearance and decorative performance of the coating film. The distinctness of image can be measured by inspection methods or by special instruments. For example, the sharpness of image of the body coating of high-end cars today is 0.8~1.0 (PGD value), and a little lower should be in the range of 0.6~0.7. The distinctness of image of the layer should be around 0.5. If it is lower than the above specified value or the distinctness of image of the repaired coating is worse than that of the unrepaired surface, it is called poor distinctness of image.

(2) Reason analysis

① The flatness of the surface of the object to be coated is poor, the surface is rough, the sandpaper is rough or the grinding precision is not enough.

②The leveling property of the selected paint is poor or its own gloss and fineness are not up to standard, and the sharpness of image is poor. (Related instrument: Fineness Meter)

③ The coating environment is poor, and the coating surface has particles or insufficient gloss. (Related instrument: gloss meter)

④ When spraying, the atomization of the paint is poor, and the orange peel on the painted surface is serious.

⑤ The thickness of the coating is insufficient and the fullness is poor.

(3) Preventive measures

① Improve the processing accuracy of the surface preparation and leveling and grinding process to make the coated surface smooth.

②Select coatings with good leveling, fineness and gloss.

③ Improve the coating environment. High decorative painting should be carried out in clean and dust-free painting booths and dry places (drying rooms).

④ Choose a Spray Gun with good atomization performance, master the correct spraying technology and construction viscosity, so that the coating can achieve a good atomization effect.

⑤ High decorative coatings generally use multi-layer coating systems to increase the thickness of the coating to improve the fullness and smoothness of the coating.

(4) Remedy

If the sharpness of image is still not good after grinding and polishing after the coating is dry, it is necessary to choose a repair topcoat with better sharpness of image and respray it.

2. Sheet metal defects

(1) phenomenon

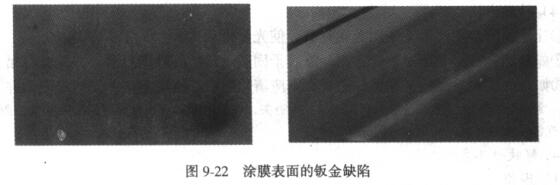

The surface of the coating film is uneven, and there are many ripples or straight, curved, crossed grooves, or spherical protrusions, as shown in Figure 9-22.

(2) The main reason

① The surface of the substrate is rough and uneven.

②The quality of atomic ash (finished putty) is too poor, the construction method is incorrect, and the surface is unevenly polished.

③ The thickness of the medium coating is not enough. (Related Instruments: Thickness Gauge)

④ When the primer is too thick and not fully cured, the topcoat is sprayed on it.

(3) Preventive measures

① Before painting, carefully check the surface of the base material, repair all defects, use appropriate grinding wheels, sandpaper, car body files, etc. to remove welding slag on the surface and inspect the surface treatment quality.

② Use the correct method to carry out the construction and grinding of putty.

③ The thickness of the middle coating should be appropriate and fully cured.

(4) Repair method

Remove the coating film on the defective part to the substrate, repair all defects on the substrate surface, and re-spray after cleaning the substrate surface correctly.

- 1Determination of the distinctness of image film: the fusion of beauty and performance

- 2Determination of the freshness of coating film by freshness Tester

- 3The importance of paint gloss detection | Gloss detection instrument

- 4What are the instruments and methods for measuring film distinctness of image?

- 5Erosion behavior and mechanism of steel structure surface coating in aeolian sand environment

郝贠洪;邢永明;杨诗婷 - 《摩擦学学报》

- 6Printing ink coating surface performance analysis

- 7Study on Wear Resistant Coating on Resin Surface

- 8Tinned steel plate surface glossiness rolling transfer control

- 9Gloss detection of clothing fabrics