Puttying considerations

①The surface to be coated needs to be completely dry before scraping to prevent air bubbles or cracks. The bottom surface is well bonded; ② It should be scraped in one or two back and forth, the technique should be fast and steady, and it should not be dragged back and forth. Too many times of dragging and scraping, the finished product is easy to fluff, the surface is uneven and not bright, and the paint in the putty will be newly transferred to the surface, causing the surface to dry and the inside to be dry, which will affect the performance. The operation sequence of scraping a coated object should be first Up and down, first left and then right, first plane and then correct angle, after scraping, wipe off the part of the rattan that should not be scraped in time, so as not to be difficult to clean after drying;

③ Holes and gaps should be filled with putty with the tip of a scraper, but do not scrape too much or too thick at one time to prevent it from drying out;

④ When scraping, the residual putty around the surface should be scraped off in time, otherwise the residual putty lumps will be left on the surface, which will increase the workload of polishing after dry operation;

⑤It is not advisable to add too much water to the self-mixed tung oil thick paint gypsum putty, and the added hot phase oil should not be too little, so as to prevent the putty from turning into powder, and it is easy to foam and fall off after scraping;

⑥ To refer to the surface shape of the object to be coated and the scraping requirements, and correctly select the scraper. Choose a scraper with a wide blade. When operating, hold the scraper with both hands, and use both hands with equal force. When using the scraper to control the putty from the putty tray, only one side of the scraper should stick to the putty. After the putty dissecting tool is used up, To clean and then save. The scraper edge and plane should be flat without gaps to ensure the quality of putty scraping.

⑦In season, the weather is hot and the temperature is high, so the putty is easy to operate. The finished putty can be covered with a thinner, and the self-prepared gypsum putty can be covered with a damp cloth or wet paper. Put it in a warm place in winter to prevent freezing. Varnish and solvent, but it should not be stored for a long time. Putty should not be stored in an open container for a long time, so as to avoid the deterioration of the adhesive and the volatilization of the solvent, causing problems such as not sticking, falling off or difficult to scrape.

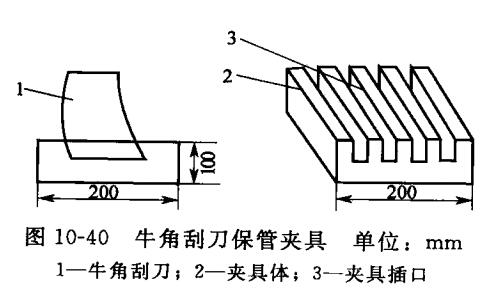

⑧The scraper will inevitably be damaged during use. It should be repaired in time to keep the cutting edge straight. The scraper should be cleaned in time after use. The scraper should not be heated or soaked in solvent for a long time to prevent deformation and bending. The horn scraper will be deformed if it is not stored properly for a long time. It should be stored with a hard wooden central tool, as shown in Figure 10-40

⑨ After the putty layer is polished, the dust on the surface should be removed so that the next layer of putty or primer can be scraped. Refer to the following formula: foundry 1% (mass fraction); triethanolamine 0.2%; essence 0.00%; water balance.

- 1Three methods for determining the flexibility of putty coatings

- 2The composition of putty and the role of its various components

- 3Natural resin paint

- 4Construction technology of paint

- 5Calculation method of putty powder dosage

- 6Puttying considerations

- 7What is putty?

- 8How to solve the problem of putty residue and poor drying on the film surface?

- 9Determination of sanding property of primer and putty