Determination of coating powder non-volatile matter content and curing time test

1. What is the definition of non-volatile matter content in powder coatings? How to determine the non-volatile content?

(1) Definition

The non-volatile content is the percentage of weight loss due to the volatilization of volatile matter when a certain amount of powder coating is baked under specified temperature conditions, and the unit is expressed in %.

(2) Equipment

Oven: It can be heated and controlled to 105°C ± 2°C or 230°C ± 3°C.

Aluminum foil dish: flat bottom, diameter 50mm, height 10mm.

Balance: Sensitivity 0.0lg.

(3) Test steps

Weigh out 2.0g ± 0.1g powder sample, put it into a weighed aluminum foil dish, put the dish into an oven with a constant temperature of 105°C ± 2°C and bake for 1 hour, or in an oven at 230°C - 13°C for 5 minutes, Put it in quickly to prevent the temperature of the box from dropping significantly. After the specified time, take out the aluminum foil dish, cool it to room temperature and weigh it.

(4) Results

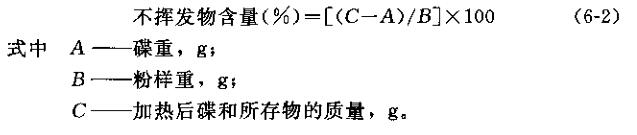

Use formula (6-2) to calculate the non-volatile matter content, accurate to 0.1g.

2. How is the "curing time test of epoxy powder" test carried out in the SY/T0315-97 standard?

(1) Test equipment

Electric Heating Plate: temperature configuration is ± 3°C.

Metal plate: the size is 150mmX150mmX25mm.

Release agent (glycerin): It is required to be able to withstand high temperature of 300°C without sticking to epoxy powder.

Touch the thermometer.

timer.

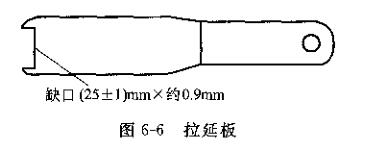

Drawn plate (see Figure 6-6 for shape).

Tweezers (small pliers).

scraper.

General purpose knife.

Differential Scanning Calorimetry (DSC).

(2) Test procedure

(2) Test procedure

① Spray two layers of release agent on the upper surface of the metal plate.

②Heat the metal plate and keep the temperature at 230°C±3°C or 180°C±3°C.

③ Use a drawing board to quickly spread the NaO powder coating on the metal plate, and apply several layers of film, so that the film thickness can be between 300 and 400 μm; when the powder removal material on the metal plate 1 begins to melt, start immediately The timer starts counting.

④ Before the coating film is completely gelled, use a general-purpose knife or scraper to divide the coating film into 10 strips (as shown in Figure 6-7) for later use.

⑤ After 30 seconds or 3 seconds, use tweezers to pick up the first coating film and immediately quench it into cold water.

⑥ Repeat the above operation once every 30s±3s. Note that they should be removed from top to bottom, quenched and placed in order.

⑦ Using a differential scanning calorimeter (DSC), according to the requirements of SY/T0315-97? Thermal characteristics test of epoxy powder and its coating? value) or curing percentage.

⑧According to the regulations of the powder coating manufacturer, the percentage curve.

(3) Test results

The time corresponding to ΔT of 2°C or the time s corresponding to 99% curing percentage.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method

(2) Test procedure

(2) Test procedure