How to prepare a test board?

(1) The material and size of the test sample substrate of the fluidized bed dip coating method (GB6554-86) are specified as follows:

A, type cold-rolled steel plate, the size is 1mmx150mmx200mm.

A2-type cold-rolled steel plate, the size is 1mmX7l11mmX100mm.

Type B steel block, the size is 10mmX100mmX150rnm, ground into a square without sharp edges, and the size is accurate to 0.025mm. The steel should meet the requirements of GB700-79 "Technical Conditions for Ordinary Carbon Structural Steel".

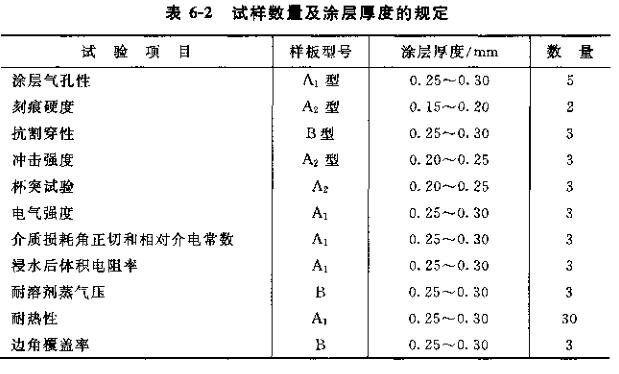

The test quantity and coating thickness of some test items are specified in Table 6-2, and can also be prepared according to relevant requirements. Items with special requirements for samples will be explained separately in this item.

Before coating, the substrate should be degreased and cleaned with a suitable solvent, and the surface should be smooth and free of rust.

A fluidized bed coating process is recommended for specimen preparation.

(2) The test panels (HG/T2006-9l, HG/T2597-94) of the electrostatic spraying method use the steel plates specified in GB/T1728, and carry out the phosphorization process after derusting and degreasing. Except for steel plates for acid resistance, alkali resistance, salt resistance, heat and humidity resistance, adhesion and cupping tests, tinplate plates are used for other tests.

The preparation of the coating film is first to put the blank sample in the powder spraying cabinet, spray with Spray Gun, high-voltage electrostatic generator, powder spraying cabinet, powder recovery device, Air Compressor and other equipment, and then keep the sprayed sample in good condition. Put it vertically into the blasting oven for curing (according to the specified temperature and time, and the thickness of the coating film is also controlled according to the specified requirements), and finally place it in a constant temperature room for 24 hours, and perform performance tests according to relevant methods.

- 1Polyurethane-graphene composite prepative film

- 2Thin layer chromatography, TLC method for preparing PLA film

- 3Preparation of silicon oxidation materials by providing hydroxyl groups with methanol

- 4Preparation and testing instrument of water-based acrylic topcoat for steel structure

胡梦 - 《华南理工大学》

- 5Preparation and performance of water dispersion and curing film for polyurethane polyol

李培礼 - 《南京理工大学》

- 6Preparation case of high temperature resistant Varnish coating

胡杰 - 《华南理工大学》

- 7Preparation of alginate biofilm

张青 - 《中国海洋大学》

- 8How to prepare film templates?

- 9Painting constructivity--general preparation method of film