Introduction of film moisture and heat resistance performance test

The moisture and heat resistance of the coating film can be determined according to the method in the National Linzhun GB/T174o-89 "Determination of Moisture and Heat Resistance of Paint Films". This standard applies to the determination of the heat and humidity resistance of paint films. Use a temperature and humidity control box to control a certain temperature, humidity and time for the test, and evaluate the grade according to the degree of damage to the appearance of the model.

(1) Materials and equipment

Temperature and humidity control box

Transparent plexiglass plate: 70mm><150rnmx(0.5~2)mm, divided into 100 equal parts.

distilled water

(2) Measurement method

According to the crystal production standard, select the substrate and supporting substrate, and make it according to "Preparation Method of Paint Film for Determination of Humidity and Heat Resistance, Salt Spray Resistance and Weather Resistance (Artificial Acceleration)" (GB/T1765).

Before testing, record the original state of the sample. Then hang the model vertically on the model frame, and the fronts of the models do not touch each other. Put it into a temperature-humidity-conditioning box adjusted to a temperature of 47°C ± 1°C and a relative humidity of 96% ± 2% in advance. When the box returns to the specified temperature and humidity, start to calculate the test time. Condensation should not appear on the surface of the sample during the test. Check once in 48 hours of continuous testing. After two checks, check every 72 hours. The template shall be repositioned after each inspection. The last inspection shall be carried out according to the times specified in the product standard; if there is no product standard, the inspection time may be determined according to the specific circumstances.

(3) Sample inspection and rating

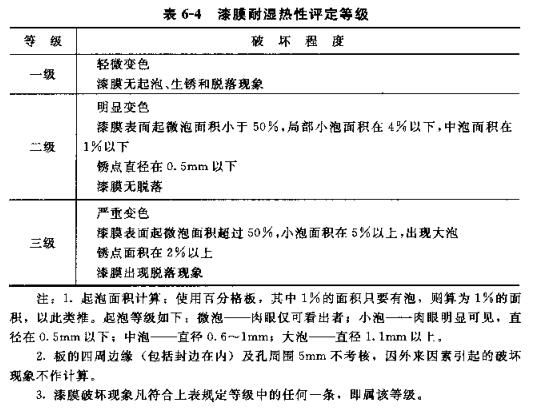

During the inspection, the surface of the model board needs to be free of fingerprints, and compared with the plant standard under sufficient light or direct light, the result is based on the two boards with the same grade among the three boards. The moisture and heat resistance of the paint film is evaluated according to Table 6-4.

- 1ASTM paint film physical properties related testing standards

- 2How to measure the moisture and heat resistance performance of Coatings?

- 3Types of Film Optical Properties Testing Instruments

- 4Testing of film resistance to neutral salt spray

- 5Moisture heat resistance of film

- 6Film performance inspection - Preparation of test plate

- 7Motorcycle film mass inspection?

- 8Film weathering resistance rating summary

- 9Moisture and heat resistance of film

-

JINGKELIAN QNF Backtack Tester 3 pcs$ 190.00