How to measure film ageing resistance?

1. Artificial accelerated aging test

The aging (artificial acceleration) performance of the coating film can be determined by the method in the national standard GB/T1865-8o "Determination of Paint Film Aging (Artificial Acceleration)". This standard applies to the evaluation of the weather resistance of paint films. The artificially accelerated weather resistance Test Chamber is used to evaluate the grade based on the degree of damage to the appearance of the test panel.

(1) Materials and equipment

①Artificially accelerated weather resistance Test Chamber

Light source: 600oW water-cooled tubular xenon lamp l Distance between test board and light source: 35~40cm.

b. Voltage stabilizer: CZ-63 magnetic saturation voltage stabilizer or other voltage stabilizer.

② Test water: distilled water is used for cooling the xenon lamp, and water purified by ion exchange trees is used for rainfall.

③Other materials and inspection equipment are the same as those specified in GB/T1767-79l "Determination of Atmospheric Aging of Paint Films".

(2) Test conditions

①Temperature: The air temperature in the studio is 45°C ± 2°C.

②Relative humidity: 65%~75%.

③Rainfall cycle: It rains for 12 minutes every hour.

For special-purpose paints, the test conditions can be selected according to the use environment and requirements.

(3) Experimental steps

①According to the product standard, select the base material and supporting primer according to GB/T1765 "Preparation method of paint film with resistance to heat and humidity, high salt resistance, and weather resistance (artificial acceleration)" to make each test panel.

② Test two test panels for each variety, and record the original state of the test panels before testing.

③Put the test panel into the central rack of the test panel, insert it into the drum of the Climate Chamber, start the machine according to the operating procedures of the Artificial climate Chamber, and carry out the test under the test conditions.

④ Start to stop the machine every 48 hours to check the test plate, and then check it every 96 hours after 192 hours. After each inspection, the positions of the test plate and the bottom are exchanged.

⑤ The termination index should be determined according to the degree of aging and damage of various paint films and specific requirements. Generally, when the damage of the paint film reaches any item in the "bad grade" of the comprehensive rating of GB/T1766 "Paint Film Aging Test Evaluation Method", the test can be stopped.

(4) Inspection and rating of the test panel Take off the test panel, dry the water drops on the back with a towel, place it on the test bench facing up to dry, and then immediately inspect it according to GB/T1766 "Grading Method for Paint Film Aging Test". Check and grade.

2. Natural weather aging test

The natural weather aging test of the coating film can be carried out according to the method in the national standard GB/T9276-96 "Coating Natural Weather Exposure Test Method". This standard stipulates the exposure site, exposure frame, test sample and test procedure of the coating natural weather exposure test method.

This standard is applicable to the open natural climate exposure test, and is used to evaluate the weather resistance of the coating when exposed to outdoor natural conditions.

Weather resistance is the durability of the layer under the action of natural climate factors.

Natural climate exposure is the comprehensive effect of various climatic factors on the coating placed in the natural environment.

It is used to observe the change of its performance with time.

Open exposure is a form of exposure in which the sample is placed in a ventilated atmosphere without a single cover on top and a pad on the bottom to fully withstand the effects of atmospheric factors.

(1) Exposure test site

① The exposure test field is also chosen to be established in the most severe area that can represent various climate types and under the actual use environment conditions of the tested products.

②The exposure site should be flat, open and free of water, and the grass height should not exceed 0.3m.

③ There should be no factory chimneys and facilities that can emit a large amount of corrosive chemical gases near the exposure site, so as to avoid the impact of local pollution.

④ The industrial climate exposure site should be located in the factory area. Salt and climate exposure sites should be built by the sea or on islands.

⑤ Meteorological observation instruments should be installed in the exposure test field, which is located in the exposure field adjacent to the National Meteorological Station, and the observation data of the station can be directly used. Meteorological data mainly include: temperature, humidity, sunshine hours, solar radiation, rainfall, wind speed, wind direction, etc.

(2) Exposure test rack and installation method

①The exposure frame is a support placed in the exposure field for exposing the samples. It should be made of inert materials that do not affect the test results, such as wood, reinforced concrete, aluminum alloy or steel coated with anti-corrosion paint. The structure strives to strengthen the country and withstand the strongest local wind.

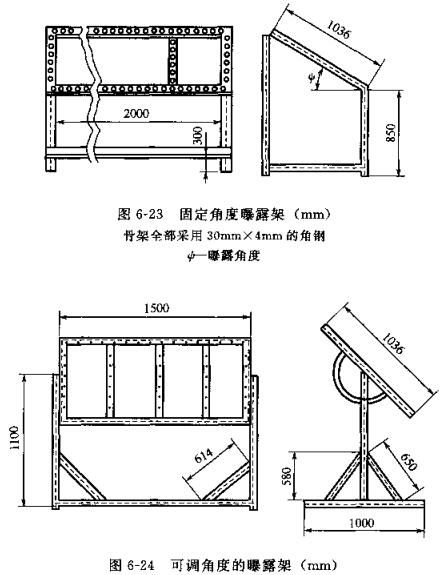

② The structure of the exposure frame is shown in Figure 6-23 and Figure 6-24. Figure 6-23 is an exposure rack with a fixed angle, and Figure 6-24 is an exposure rack with an adjustable angle.

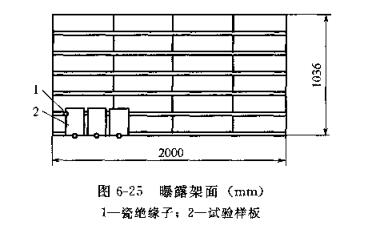

③ The sample in the exposure frame should be in contact with the metal ground, and should not be in contact with wood or porous materials as much as possible. It is recommended to use porcelain insulators to draw the template (see Figure 6-25). Porcelain insulators are fixed on the frame surface, and the template is placed in the grooves of the three porcelain insulators and can move up and down.

④ The placement of the exposure racks should ensure that the rack space is free and ventilated, avoid mutual blocking of sunlight and facilitate work, and the row spacing is generally not less than 1m.

⑤ The bottom of the exposure frame should be no less than 0.5m from the ground.

⑥ The exposure rack faces the equator and exposes the model at 45° to the horizon. In order to allow the surface of the model to receive the maximum amount of solar radiation, the exposed rack surface and the horizon should be placed at the local latitude angle.

(3) Test procedure

①After the sample is adjusted to the specified state, the appearance of the film should be observed first, such as gloss, color, and physical and mechanical properties required to be measured, and the original records should be made, mainly including: type of substrate, name of primer and surface material, Original light selection, primer thickness, total thickness, surface condition of the paint film, and test date, etc.

②The results of the exposure test will change with the test season, although this effect will be reduced with the extension of the exposure time. When the exposure period is less than one year, if the complete characteristics of the product are to be obtained, a repeat test shall be carried out on the sample after six months. The exposure test season is generally stipulated in late spring and early summer every year.

③ Year and month are used as the time unit of the exposure test. If there are no special regulations, within three months of the test, check every half a month; after three months to one year, check once a month; after more than one year, check every three months. It is also possible to use a certain amount of solar radiation on the surface of the model as the exposure period. When the weather changes suddenly, it should be checked at any time, and if there is any abnormal phenomenon, it should be recorded or photographed.

④ If specified in a certain exposure period, wash the whole or part of the sample. Rinse with cotton wool in tap water before inspection, and inspect after drying; if it is required to polish the sample, use the specified polishing agent to polish and then inspect.

⑤ The exposure period of the sample can be in accordance with the requirements of the product standard or the estimated time (month, year), or the amount of solar radiation received by the sample can be used as the exposure period, or it can be stipulated that the exposure sample reaches a certain degree of aging damage as the exposure period.

⑥ As a sample of corrosion test, before putting into test, the product standard stipulates to draw a scratch with a deep visible bottom on the coating film, with a width of 0.5~1mm, and check the damage on both sides of the scratch.

⑦ The exposure sample shall be measured according to GB/T9754, GB/T9761 and GB/T11186.2, and the aging-evaluation of the coating shall be carried out according to GB/T9277.

⑧ In the exposure test site with a lot of wind, sand and dust, the surface of the model should be cleaned frequently with a soft broom, so that the model can be fully affected by atmospheric factors.

- 1Coating performance testing: the key to ensuring quality coatings

- 2The relationship between natural aging and accelerated aging

- 3Artificial climate accelerated weathering test and natural aging conversion

- 4Application of accelerated weathering Test Chamber in respirator

- 5UV accelerated weathering Test Chamber for weathering resistance of epoxy resin

- 6Application analysis of ultraviolet accelerated weathering Test Chamber in PEVA film

- 7Application and test method of UV accelerated weathering Test Chamber in automotive Glass film

- 8Application of xenon arc aging Test Chamber in outdoor Coating

- 9Application of xenon arc aging Test Chamber in water-based paints industry