How to Measure Color by Turntable Colorimeter?

The main part of this instrument (Fig. 3) is a disc made of strong thick paper mounted on the shaft of a small electric motor. It is also possible to mount on that shaft a cardboard disc painted in a different color by suitable means. Since there is section AB (Fig. 4) on the disks, one disk can be inserted into the other, so that sectors of desired size are exposed from each disk. This set of discs is mounted on the tray of the instrument. Because the area of each sector is proportional to the length of its arc when the radius is the same, the area of each sector can be measured by the percentage of the area of the circle. Arcs are measured using graduated circles in degrees (from 0 to 100) engraved on the circumference of the instrument dial. On the same axis of the messenger, a disc with a smaller diameter can also be installed. Its sector area can be measured with a smaller graduation ring (degrees from 0 to 100). The number of revolutions of the motor should not be lower than 1800 revolutions per cent.

Standard discs are made of very strong thick paper. For color standards , various gelatin solutions with lightfast organic dyes are generally used. For white standards, sulfuric acid town is used, and for gray standards, a mixture .

Achromatic color standards should have a dull surface; the surface must not contain any chromatic colors. .The standard color should have high light fastness, that is, it will not fade after being exposed to light for a long time. The use of light-fast organic dyes as color standards is not allowed. Shvin Yersan and Dimkina9 proposed the use of particularly lightfast inorganic pigments for the preparation of certain standard colors. For example, when preparing a yellow standard, it is recommended to use bright chrome yellow; when preparing a blue standard, use cobalt blue-containing cobalt blue (brand yKX); when preparing a black standard, use charcoal black, etc.

When the color standard is prepared according to the Kandelian method, a colored adhesive layer must be applied to a glass plate washed with petrolatum oil (vaseline) and talcum powder and placed horizontally. On the dried glue layer, paste a piece of smooth and durable thin paper; when the glue is dry, peel off the glued paper from the glass.

According to Shwin Yersan and Somkina, a simpler method can be used to prepare color standards. It is to stick the strong and smooth sheets of paper together with wood glue solution (100 grams of glue, 150 grams of water, 10 grams of oil), then stack several sheets of paper together, put them on a press and roll them pressure. After dry operation, apply a color glue layer made of suitable pigments (pigments are miscible with 3% gelatin solution) on the paper sheet, and after the color paper is dried, cut it into a circle with a diameter of 20 cm.

The graduation of the color standard is carried out in advance on the three-color Colorimeter under the standard light source.

For this reason, a three-color circle painted with red, blue, and green with a larger diameter (the colors should be as harmonious as possible, see the previous method for its preparation) should be installed on the shaft of the motor; Color the circle with the smaller diameter. The size of the red, green and blue sectors is properly selected by starting the motor, so that the color tone formed when the large circle rotates is completely similar to the color tone of the small circle.

For a complete determination of the color being tested, it is necessary not only to make the circles equal in hue, but also to make them identical in lightness and saturation. Therefore, it is necessary to put the black circle on the inner disk or the outer disk, or put a circle of one of their main color colors on the inner disk.

After a series of trials, when the large disk and the small disk show the same color, immediately measure the area of each sector. The measured color is represented by the sum of the sector areas. Using the aforementioned Colorimeter, the hue, brightness and saturation of the tested color can be quantitatively measured. As pointed out by MM Gurevich5, in order to ensure the reliability of the measurement of this disc Colorimeter, it is necessary to pay sufficient attention to the light source for illuminating the disc surface as for other precision instruments.

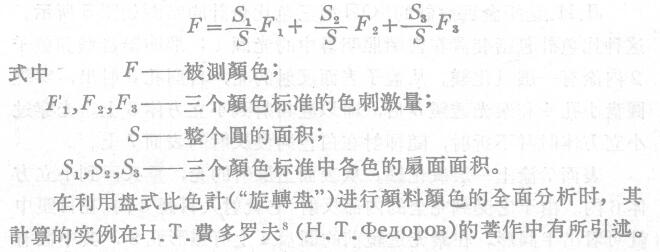

When measuring on a disc Colorimeter, the calculation is carried out by multiplying the amount of chromatic stimulation of each color by the relative area occupied by this color on the circle.

- 1How the Colorimeter works

- 2Determination of the color of transparent liquids with a Roviben Colorimeter

- 3Test method for color of adhesive resin - Platinum cobalt colorimetric method

- 4Colorimeters vs Spectrophotometers: Understanding the Differences Between Color Measurement Techniques

- 5Use of Colorimeters

- 6The principle and use of Colorimeter

- 7What is a Colorimeter? Types of Colorimeters

- 8What types of Colorimeters are there?

- 9Functional Comparison of Colorimeter and Spectrophotometer

-

-

-

-

-

-

HANNA HI784 Ion Meter Tintometer$ 225.00