Introduction of thermal transfer decoration method

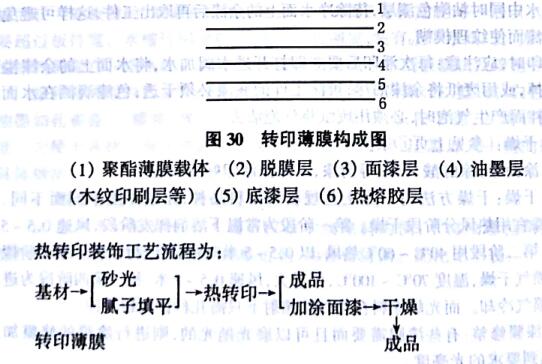

Thermal transfer decoration, also known as hot stamping decoration, is a decoration technology that uses a special transfer film to transfer the wood grain decoration layer on it to the surface of the furniture through heating and pressure. This method can transfer many varieties of designs and colors, such as marble pattern, metal foil, monochrome film and so on. Because no liquid remover and adhesive are used in thermal transfer printing, the process is simple, low cost, energy saving, pollution-free, and the effect of installing ft cloth is better, so it is widely used for surface decoration of furniture, wood-based panels, plastic leather, metal and other materials. decorative applications. In recent years, 8% to 9% (approximately 160,000 to 180,000 cubic meters) of U.S. MDF production has been decorated with heat transfer printing, and furniture decorated with heat transfer printing accounts for 10% of the total U.S. furniture production. my country has successfully applied this technology to furniture finishes. The composition of the transfer film is shown in Figure 30, which is the key material for transfer decoration. One body is a 12-30-meter polyester film, which is heat-resistant and has sufficient flexibility. The carrier is to be separated from the wood grain decoration layer left on the furniture surface after hot stamping. -, so there must be a film layer made of wax. The topcoat layer is used to protect the printed wood grain and the primer layer, usually a colorless transparent layer. When color is required, coloring agents can also be added to the top coat, the top coat is acrylic resin, etc., each layer is about 125-15 microns thick, and there are one to multiple layers. The wood grain printing layer or other patterns are printed with ink. If it is a metal foil layer, the metal is heated under high vacuum conditions to vaporize the metal and evaporate to the inner surface of the topcoat layer. Usually the metal foil is pure aluminum with a thickness of 210-25 microns. The adhesive is hot-melt adhesive. When the hot-melt adhesive is heated at 140°C~200°C, it will melt rapidly, and when it cools, the decorative layer (including topcoat layer, printing layer, and primer layer) will be firmly adhered to the furniture substrate. .

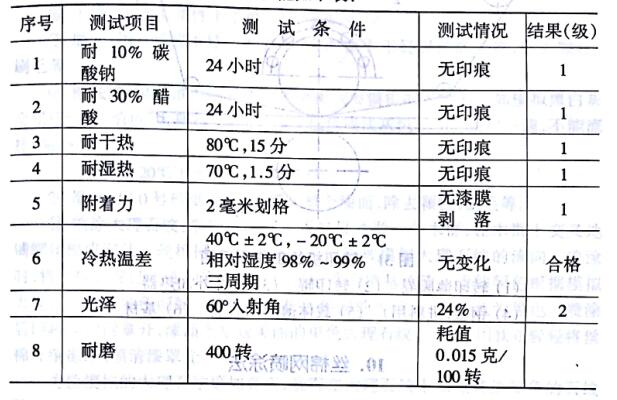

The total thickness of the domestic transfer film is 0.035 ~ 0.05: mm, the thickness of the decorative layer is 0.01 ~ 0.015 mm, the width of the transfer film is generally 48 inches or 60 inches, and can be cut according to the specifications of the components to be installed. The physical and chemical properties of the domestic transfer printing decorative layer are as follows:

For the surface treatment of the substrate, since the thickness of the thermal transfer decorative layer is only about 0.015 mm, the surface quality requirements for the decorated furniture and wood-based panels are relatively high, the surface roughness should be small, and the peel strength of the substrate surface should be > 1 N/m mm2, the plate thickness deviation should be <±0.2mm. Good medium-density fiberboard and fine-porous plywood have a surface roughness of 20-.30 microns after polishing, and can be directly decorated by thermal transfer printing. Coarse-porous plywood, medium-density fiberboard with poor surface performance of particleboard, etc. need to be putty after sanding. , Solvent composition.

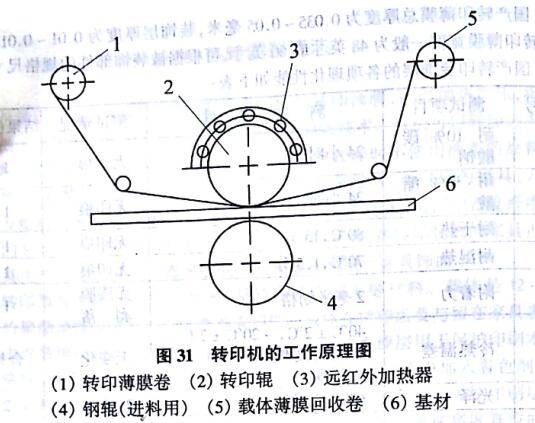

There are two methods of heat transfer printing: flat pressing and rolling pressing. Generally, rolling pressing is suitable for furniture panels and wood-based panel decoration. The working principle of the pressure transfer machine is shown in Figure 31. After the transfer film is unrolled, it is sandwiched between the silicone rubber roller and the decorative plate. The rubber roller is heated by far infrared rays, and the temperature reaches 140°C~200°C. Under the pressure and heating of the silicone rubber, the hot melt adhesive layer on the back of the transfer film is activated and adhered to the decorated workpiece, and the wax release layer separates the decorative layer from the polyester, the carrier, and transfers When it is cooled, the decorative layer is firmly adhered to the surface of the workpiece. When thermal transfer printing, the temperature, pressure and feeding speed should be reasonably determined, so as to ensure the quality of transfer printing decoration.