What equipment is required for airspraying?

The air spraying device is mainly composed of an Air Compressor, an oil-water separator, a Spray Gun, an air hose, and a paint tank.

(1) Air Compressor

The maximum pressure of the Air Compressor is 0.7MPa (no load). The capacity of the Air Compressor is determined by the air consumption of the Spray Gun, and the spraying pressure of any Spray Gun should always be guaranteed at 0.35~0.6MPa. During use, open the drain hole of the air tank every day to drain the oil and water (Figure 2_2_1). In order to prevent the influence of oil and water in the compressed air on the coating film, it is also necessary to configure an oil-water separator to purify the air.

(2) paint cans

In batch operation, a pressure paint tank should be configured, and the sealed paint tank should be equipped with stirring, heat exchanger, compressed air inlet and outlet, pressure device, paint filter and outlet. The volume of paint delivery is generally between 20~120L, and the applied pressure of paint is 0.15~0.3MPa (depending on the number of Spray Guns).

(3) Spray Gun

1. Classification of Spray Guns

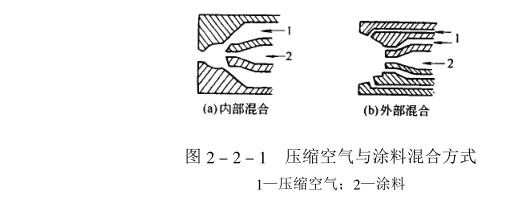

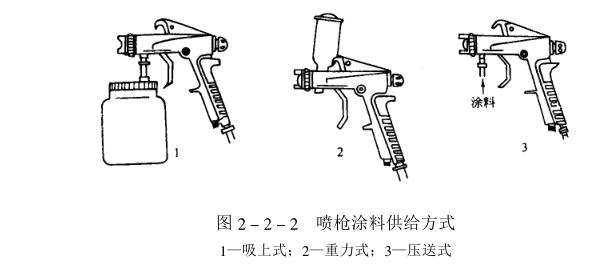

The Spray Gun is the most critical part of air spraying. There are many types of Spray Guns. According to the atomization method, there are internal mixing and external mixing. Internally mixed spray patterns are limited to circles, ideal for spraying small objects and colorful paints. The spray shape of external mixing can be adjusted, which is suitable for large and small workpieces of various shapes, so external mixing Spray Guns are generally used. Spray guns are divided into three types according to the paint supply method: suction type, gravity type and pressure feeding type (Figure 2_2_2).

The suction Spray Gun relies on the negative pressure generated by the high-speed airflow at the nozzle to suck the paint and atomize it. Its paint spraying volume is greatly affected by the viscosity and density of the paint, and it is also related to the nozzle diameter. Although the large-caliber Spray Gun has a large amount of paint, if the air pressure is not enough, it is easy to cause poor atomization. The capacity of lacquer is generally about 1L, which is suitable for small batches of non-continuous operations.

The paint of the gravity Spray Gun is above the Spray Gun, and the paint flows to the nozzle by the gravity of the body, all of which have the negative pressure effect of the high-speed airflow, so the amount of paint produced is larger than that of similar suction Spray Guns. The volume of the paint is generally 250~500m1, the amount of spraying is small, but the cleaning is quick and convenient, and the color change is easy. A large number of spraying operations can also be satisfied by replacing the elevated tank.

The pressure-fed Spray Gun is light and flexible, and the amount of paint output can be greatly adjusted according to the paint pressure. It can be used for multiple Spray Guns to work at the same time to meet the needs of mass production operations. In addition to the above-mentioned basic types of Spray Guns, there are also long-head Spray Guns. , long-handled Spray Guns, fog-free Spray Guns, automatic Spray Guns, etc., which can meet various special production operations.

2. Spray gun structure

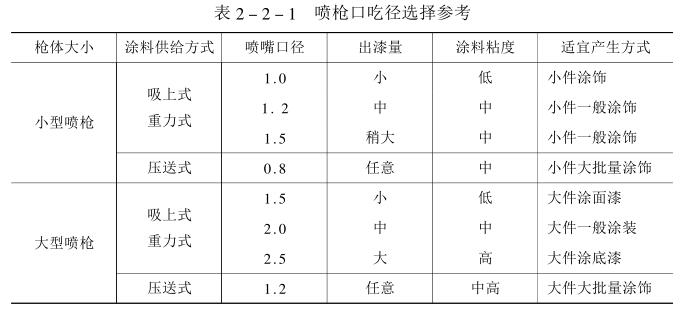

The Spray Gun is composed of three parts: spray head, adjusting parts and gun body. The spray head is composed of air cap, nozzle, needle valve, etc. It determines the atomization of the paint and the change of the spray shape. The adjusting part is used to adjust the air flow and the amount of paint sprayed. , the nozzle is two concentric circles, which constitute the paint and air channel, the inner circle is the paint outlet, which is easy to be worn by high-speed paint flow, made of wear-resistant alloy steel, the gap between the inner circle and the outer circle is only about 0.3mm, and the air jet is very fast Intense, so that the paint outlet generates negative pressure to suck out the paint and is atomized. The nozzle diameter is between 0.5~5mm, and the low viscosity colorant uses a 0.5~0.8mm nozzle; the top coat uses a 1.0~1.5mm nozzle; the primer 2.0~2.5mm caliber nozzles are used for intermediate coatings; 3.0, 4.0mm or 5.0mm caliber nozzles are used for high-viscosity paints, and large caliber nozzles should be used for viscous paints such as plastisol, anti-sound slurry, and anti-stone impact coatings. Nozzles, due to the large difference in the paint output of various Spray Guns, such as the suction Spray Gun, the paint output is small, and the nozzle diameter should be slightly larger than that of the pressure feed type. The appearance quality has a great influence, so the caliber of the Spray Gun used for spraying the topcoat should be smaller than that of the primer, and the caliber of the commonly used Spray Gun is between 1.0 and 2.5mm. For the selection of the caliber of the Spray Gun, see Table 2_2_1.

The air cap has a central air hole, auxiliary air holes and side air holes. The porous type has high performance, the central hole is used to atomize the paint, and the side holes are used to change the spray shape. Opening and increasing the air flow of the side holes can change the spray pattern from round to oval, or even a larger flat pattern. The auxiliary air holes make the paint mist particles finer, more evenly distributed, and the spray width wider, preventing paint from being deposited around the nozzle.

The air cap, nozzle and needle valve are a set and should not be combined randomly, and should be replaced as a complete set when worn.

- 1Application and classification of lame plating technology

- 2Basic Principle and Application of Permanent Magnet Air Compressor

- 3Types of Spray Guns commonly used

- 4How to properly operate and maintain the Spray Gun?

- 5Why does the coating have orange peel defects? How to solve sagging and leakage?

- 6What are the tips to prevent sand inclusion and dry spray of paint film?

- 7The relationship between Spray Gun caliber, paint viscosity and coating type of electric airless sprayer

- 8Spraying of power tools - Spray Guns

- 9Several solutions for double coating