Introduction to the operation method of air spraying

(1) Coating atomization characteristics

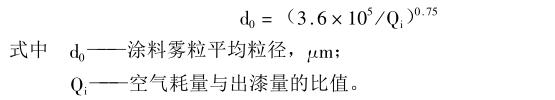

The atomized particles of the paint are fine, the atomization effect is good, and the appearance quality of the coating film is also good. The atomization characteristics can be described by the following formula:

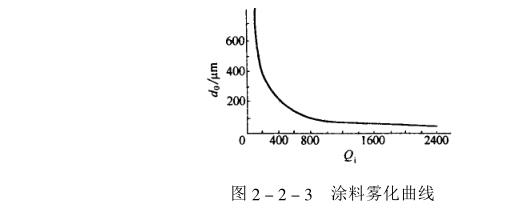

Understand d more intuitively from Figure 2_2_3. The relationship between Q and Q. When the Q, value is small, the ratio of air consumption to paint output has a great influence on the atomization effect. At this time, increasing the air consumption or reducing the paint output will obviously improve the atomization effect. To increase the amount of air can be achieved by increasing the air pressure, but pay attention to higher air pressure will make the paint mist fly more seriously.

(2) Paint output

The amount of paint output should be determined according to production needs. Depending on the size of the workpiece, small or large Spray Guns are selected respectively. For suction or gravity Spray Guns, increasing the compressed air pressure is very limited to increase the paint output, and is limited by atomization. Generally, adjust the needle valve to increase the paint output appropriately. A better way to increase the amount of paint is to use a larger caliber Spray Gun. For example, the maximum caliber of 1.5mm can be used for the top coat, and the maximum caliber of 2.5mm can be used for the primer. It can be adjusted arbitrarily according to the paint pressure, so the caliber of the Spray Gun is relatively small.

(3) Spray range

The air pressure has little effect on the spray pattern, so usually it can only be adjusted through the auxiliary air hole, and it can be adjusted to an appropriate range according to the size of the workpiece.

(4) Paint mist deposition amount and film thickness uniformity

The amount of paint mist deposition decreases proportionally with the extension of the spraying distance. The spraying distance of small Spray Guns is 15~25cm, and the spraying distance of large Spray Guns is 20~30cm. If the spraying distance is too far, the coating film will be thin and rough; Thick and sagging, coupled with the airflow rebound effect will also produce orange peel phenomenon. The uniformity of the film thickness is related to the moving speed of the Spray Gun and the overlapping of the graphics. If it is too slow, it will cause sagging, and it will cause serious sagging when it stops for 0.ls. Therefore, the shooting point and stopping point must not face the spraying area. The spray pattern is generally thick in the middle and thin in the periphery. For the uniformity of coating film thickness, 1/2 overlap is used for circular shapes, 1/3 overlap is used for oval shapes, and 1/4 overlap is used for flat shapes.

(5) Effect of paint viscosity on atomization

In addition to affecting the paint output, the viscosity of the paint also greatly affects the atomization effect (see Figure 2_2_4). Different paints have different spraying viscosities due to their different characteristics. The time for acrylic baking varnish and amino baking varnish is 18~25s, and that of alkyd paint is 25~30s. It needs to be adjusted to the respective spraying viscosity according to a certain dilution ratio during construction. The viscosity of the paint is also greatly changed by the change of ambient temperature (see Figure 2_2_5 ), so it is advisable to keep the temperature of the paint at 20-30°C during a large amount of spraying operations, so as to avoid poor atomization due to high viscosity of the paint when the temperature is low, resulting in uneven coating and poor appearance .

- 1Factors Affecting Coating Viscosity

- 2Coating viscosity determination and viscosity influencing factors

- 3Paint viscosity

刘登良 - 《《涂料工艺》》

- 4Determination of paint viscosity

- 5Water-based paint laboratory testing project procurement instrument selection plan

- 6Control the viscosity of uniform filament coatings

- 7How to measure Coating viscosity with ISO cup

- 8How to measure Coating Viscosity?

- 9How to save time and money with proper measurement Viscosity?