Ship painting thickness of dry film detection and film thickness data recording

1. Detection of dry film thickness

Dry film thickness detection needs to be measured with a Film Thickness Gauge after the coating is dried.

When the rough steel plate is coated with a thinner primer (such as shop primer), the direct measurement with a dry Film Thickness Gauge appears to have a large error. At this time, it is necessary to fix the smooth test panel with adhesive tape, let the test panel and the steel plate be coated at the same time, and then measure the thickness of the paint film on the test panel. The usual film thickness measurement can be carried out directly on the coating.

When testing, the selection of measuring points should pay attention to the uniformity and representativeness of the distribution. For the flat surface of the hull (such as hull plating, deck, outer surface of superstructure, etc.), take a point every 20m2 or so to test its thickness. For the complex surface of the hull structure (such as the interior of the tank, the interior of the double bottom, etc.), the thickness should be measured at a point every 10m2 or so, and there should be more than 1/3 of the frame profiles, and the surface and both sides should have evenly distributed 2 ~3 detection points. For smaller areas or components such as small cabins and small liquid tanks, it is necessary to ensure that each side should have more than three detection points. However, the surface of the weld does not need to be tested within 30mm from the free edge and where it is difficult to detect.

2. Film thickness data record

On-site records should be made for each painting operation. Film thickness testing and data recording should be in charge of special personnel.

For non-decorative surfaces, the film thickness detection data can be directly written on the coating with an appropriate marker pen, so as to facilitate the adjustment of the construction thickness when the subsequent coating is painted, and then transfer the data to the record sheet. The data record sheet should be kept for a certain period of time, even if the film thickness is passed the inspection, it cannot be discarded, at least it must be kept until after delivery for reference.

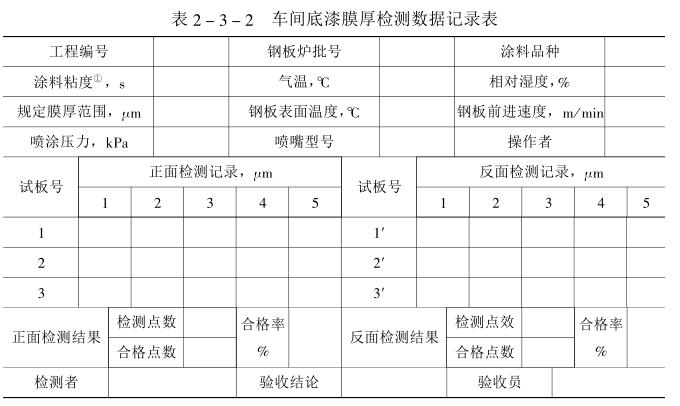

Table 2_3_2 is the shop primer construction and film thickness data recording table (style) on the steel pretreatment line. Table 2_3_3_ is the hull coating construction and film thickness data record form (style).

①The paint viscosity is based on the outflow time of 4 cups of paint.

- 1Paint thickness Detector purchase to understand these points

- 2Comparison of three popular coating thickness measuring instruments under 1,000 yuan

- 3Film Film thickness detection method

- 4How to test container dry film?

- 5Test of film thickness of workshop primer

- 6Detection of dry and wet films for container coating

- 7Overview of Coated Film thickness detection method

- 8Coating Thickness Gauge for railway Film thickness detection

- 9Correct use of Film Thickness Gauge

张瑞;张月富