Airspraying precautions

In the operation process of air spraying operation, spray distance height, Spray Gun operation mode, spray pattern overlap and paint viscosity are the four main points of spraying, which are also the basis of spraying technology, and need to be mastered.

(1) Spray distance height

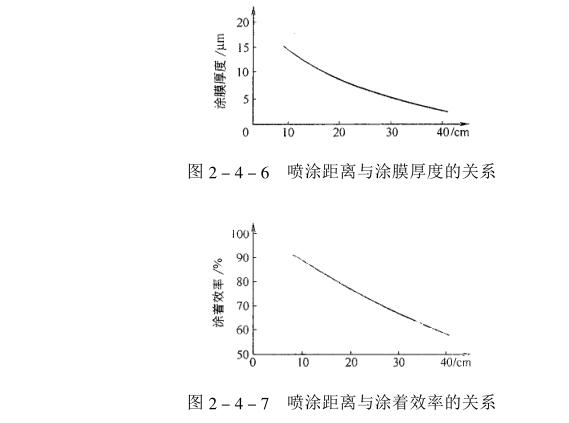

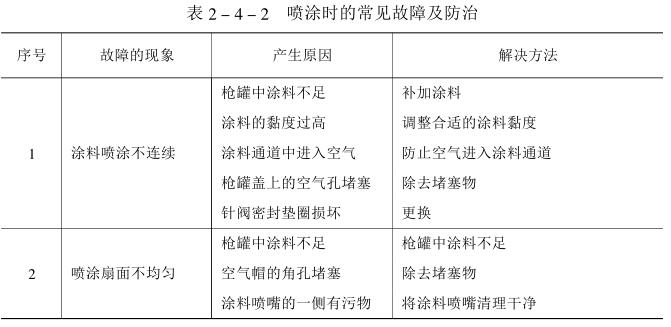

It refers to the distance between the gun head and the object to be coated. Generally, the spraying distance of the Spray Gun with a caliber below 15mm is 15~20mm; the spraying distance of the Spray Gun with a h diameter higher than 1.5mm is 20~30mm; the spraying distance of the air atomized portable electrostatic Spray Gun is 25~30mm. During the spraying process, the spraying distance must be an important factor to ensure the uniform thickness of the coating film. In order to achieve this goal, the Spray Gun needs to be perpendicular to the object to be coated during spraying, and the running track should be kept parallel to the object to be coated. If the Spray Gun and the object to be coated run in an arc during spraying, there must be a large difference in the thickness of the central part and the west side of the sprayed workpiece. Under the same conditions, if the spraying distance is too short, the paint is easy to form; if the spraying distance is too long, the paint film becomes thinner, the paint is wasted, and it is easy to cause paint film defects such as void paint. The relationship between spraying distance and coating film thickness and coating efficiency is shown in Figure 2_4_6 and Figure 2_4_7.

(2) Spray gun operation mode

Including the angle between the Spray Gun and the object to be coated and the running speed of the Spray Gun. The Spray Gun and the object to be coated should be at right angles and run vertically. If the Spray Gun is inclined or runs in a circular arc, a uniform thickness of the coating film cannot be obtained. The running speed of the Spray Gun is generally controlled within the range of 39~60cm/s, and the actual running speed is determined according to the amount of paint sprayed and the complexity of the workpiece.

(3) Lap joint of spray pattern

It refers to the partial overlap of the sprayed spray pattern, and the width of the overlap should be consistent. The degree of overlap between the front and rear is generally 1/4~1/3 of the effective spray pattern. If the width of the overlap is variable, the film thickness is not uniform. can produce streaks or blotches,

(4) Coating viscosity

The viscosity of the coating needs to be adjusted within the range specified by the process. When the viscosity is too high, the atomization of the coating will be poor, the coating will not be easy to spray out, and defects such as orange peel will easily occur; Defects such as sagging.

The construction viscosity of different types of coatings is not the same, and the construction viscosity should be determined according to the construction requirements of the coating during construction.

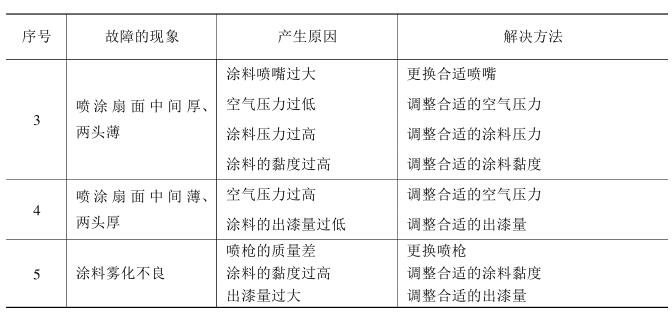

(5) Common faults and prevention during spraying

See Table 2_4_2 for common faults and prevention during spraying.

- 1Application and classification of lame plating technology

- 2Types of Spray Guns commonly used

- 3How to properly operate and maintain the Spray Gun?

- 4Application of Rotational Viscometer in surface Coating viscosity measurement

- 5Application of Rotational viscometer in Coating Viscosity Detection

- 6Why does the coating have orange peel defects? How to solve sagging and leakage?

- 7What are the tips to prevent sand inclusion and dry spray of paint film?

- 8The relationship between Spray Gun caliber, paint viscosity and coating type of electric airless sprayer

- 9Spraying of power tools - Spray Guns