Scratching operation steps and precautions

1. Scraping operation steps

The scraping operation is usually divided into three steps: smearing, scraping, and trimming, but it should be used flexibly according to the requirements of scraping. There is a difference between the three steps of puttingty with slow drying speed and putty with fast drying speed. The former can be clearly divided into three steps, while the latter, such as perchlorethylene resin putty, dries quickly and cannot be clearly divided into three steps when scraping. Wiping, scraping, and trimming should be completed in one continuous step.

(1) Smudge

Wiping is to use a scraper to spread the putty on the surface of the object to be coated. When wiping, first use the scraper to dig out the putty from the putty tray, and then attach the edge of the scraper to the surface of the object to be coated. The initial operation of the scraper should be slightly Tilting forward, it should form an angle of 80° with the surface of the object to be coated. As the scraper moves, the putty is continuously transferred to the surface of the object to be coated. At the same time, the putty adhered to the scraper is gradually reduced. Therefore, the scraper is required to Gradually increase the degree of forward inclination to force the putty to adhere to the surface of the object to be coated until the included angle is about 30°, then completely spread the putty attached by the scraper on the surface of the object to be coated.

(2) scrape

Scraping is to smooth the putty layer applied on the surface of the object to be coated, and eliminate the obvious traces of smearing. In normal scraping, the residual putty on the scraper should be removed first, and then the scraper should be tilted forward as far as possible to attach it to the putty layer. and scrape forward according to the running track of the scraper during smearing. As the scraper moves, the amount of putty attached to the scraper will gradually increase, and the angle between the scraper and the surface of the object to be coated should also gradually increase until the included angle Scrape off excess putty at 90°.

(3) trimming

Repair means that after the putty layer has been scraped and leveled, some uneven defects, seam marks, edge defects, etc. are repaired. When repairing, the scraper should be tilted forward, or filled with a little putty, or scraped with a scraper, and the force should not be too large , to prevent damage to the entire putty layer.

2. Precautions for scraping

(1) The putty selected should be matched with the entire coating system, that is, matched with primer and topcoat. Putty can not add other fillers arbitrarily except for the matching thinner to adjust the consistency.

(2) Before scraping, the surface of the object to be coated should be cleaned to remove dust, water, oil and other dirt. If the original primer paint film is found to be peeling off or rusted before scraping, the surface treatment should be carried out again, and the putty can only be scraped after recoating the primer.

(3) According to the surface shape of the object to be coated and the scraping requirements, the scraper should be selected correctly. Choose a scraper with a wide blade, and hold the scraper with both hands when operating, and use both hands with equal force. When digging putty from the putty tray with a scraper, only one side of the scraper should stick to the putty.

(4) The operation sequence of scraping an object to be coated should be up and down, first left and right, first flat and then edges and corners.

(5) Each putty layer should not be scraped too thickly, it should be firmly scraped, no missing scraping, and there should be no air bubbles in the putty layer. The thickness of the putty layer is better controlled in the range of 0.3~0.5mm, and the second putty should not exceed 1m. The putty layer needs to be dried before the next scraping or grinding.

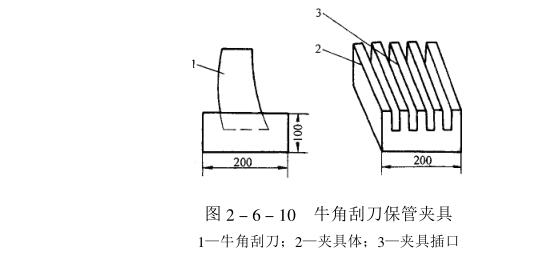

(6) The scraper will inevitably be damaged during use, and it should be trimmed in time to keep the cutting edge straight. The scraper should be cleaned in time after use. When the steel scraper is not used for a long time, it should be preserved with anti-rust oil. The horn scraper and plastic scraper should not be heated or soaked in solvent for a long time to prevent deformation and bending. The horn scraper will be deformed if it is not properly stored for a long time, so it should be stored with a hard wooden tool, as shown in Figure 2_6_10.

(7) After the greasing pan and the greasy pan are used, the remaining putty should be removed in time, and cleaned. Do not damage the bottom of the pan during standard washing, keep the bottom of the pan flat, and prevent long-term corrosion during storage.

(8) After the putty layer is polished, the dust on the surface should be removed so that the next layer of putty or primer can be scraped. When wet grinding is used for grinding, in order to prevent the steel being coated from rusting, it is better to use anti-rust water for grinding. Anti-rust water can refer to the following formula:

Borax 1% (percentage by weight); triethanolamine 0.2%; essence 0.003%; water balance.

- 1Floor painting method of painting

- 2Putty defects of atomic ash defects

- 3Common defects and prevention methods of refurbished painting --- pinholing, eye numbness, bubble

- 4New technology for automobile painting construction----flawed putty scraping method

- 5New technology for automobile painting construction--partial putty scraping method

- 6New technology for automobile painting construction-----Putty blending technology

- 7Water-based coating glue coating process FAQ and measures, how much do you know?

陈利丽; 胡敬海; 陈忠刚; 施明 - 《水性涂层胶涂层整理常见问题分析及对策》

- 8Application of RDS Mayer Rods in the preparation of polyester reticulated paint

- 9Introduction of scraping tools