Content and significance of painting surface preparation

一、前处理的内容

(1)除氧化皮和铁锈:金属在加工和存放过程中,由于受高温和各种因素的影响,易产生氧化皮和浮锈。以钢铁为例:其氧化皮和浮锈的主要成分是铁的氧化物或水合氧化物,其结构式为Fe203、Fe304、Fe203·xH20等。这些氧化物的电极电位比较高,他们的存在会加速钢铁的电化学腐蚀,同时氧化物的晶格常数比较大,脆性大,直接在锈蚀上涂装,涂膜在受到冲击、挠曲时,易开裂。因此除锈是涂装前处理的重要内容之一。

(2)脱脂:金属在加工和储存过程中,尤其在机加工过程中,易被油污污染。有些工件为防止在储存过程中生锈,还需要涂防锈油或防锈脂加以保护。油污的存在影响涂料在基体上的润湿与结合力。因此涂装前需要将基体上的油污有效清洗干净。

(3)消除机械污物:机械污物主要指粉尘、焊渣、型砂及在机加工过程中可能产生的毛刺、凹凸不平等缺陷。这些缺陷不清除,将直接影响到涂层的装饰性与保护性。

(4)转化膜处理:According to材质不同,通过不同的方式,在基体表面生成一层薄膜以提高涂层附着力和耐蚀性。一般地,在钢铁表面进行磷化处理,在铝合金表面进行氧化处理等。

(5)预涂偶联剂、特种涂料等:为增强涂层的结合力,对大型工件不便于入槽磷化处理时可涂装磷化底漆、热塑性粉末涂料预涂底漆等。

二、前处理的意义

前处理对整个涂装质量起着决定性作用,是充分发挥涂料功能的前提条件。实践证明,由前处理引起的涂层弊病,大约占整个涂层弊病的50%以上。具体来说,前处理有以下几方面的作用。

(一)通过前处理可提高涂层与基体的结合力

Van der Waals force F0c1/L 6 , where L is the distance between molecules, that is, the intermolecular force is inversely proportional to the sixth power of the distance between molecules. The attachment on the surface of the substrate is removed by pretreatment, the molecular distance is reduced, and the bonding force of the coating is greatly improved. The conversion film formed in the pretreatment is a porous substance, and the paint can fully penetrate into the pores of the conversion film to form an "anchor effect" to enhance the binding force.

(2) Enhance the corrosion resistance of the coating

A non-conductive insoluble phosphate or oxide conversion film is formed through pretreatment, which makes it difficult to form a corrosion primary battery, thus greatly slowing down the corrosion rate of the coating. It is generally believed that the corrosion resistance of the coating after phosphating will increase by 2 to 3 times, so phosphating treatment has attracted great attention from various industries and enterprises. At present, in coating production, 100% phosphating treatment is advocated.

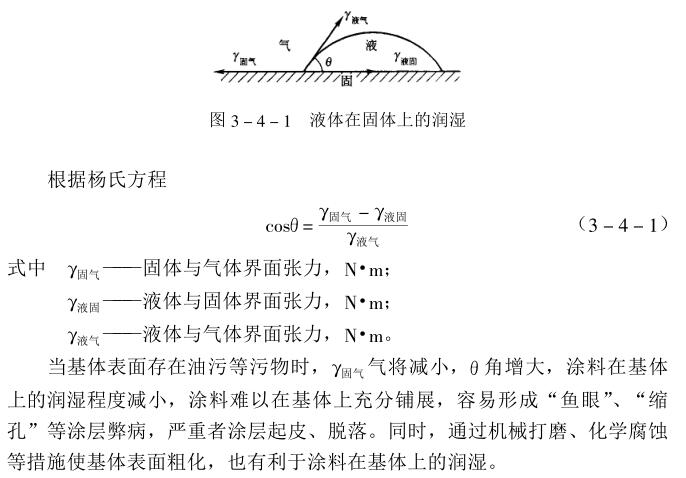

(3) Improve the wettability of the coating

The wetting of a liquid on a solid is shown in Figure 3_4_1.

(4) Improve the decorativeness of the coating

The roughness of the substrate surface directly affects the gloss of the coating. For example, cast iron, due to the rough surface, the coating is dull and dull, so it needs to be sandblasted and polished to make the surface roughness of the material reach 4~6 grades, which not only ensures good adhesion, but also ensures a good appearance .

- 1How to evaluate the surface treatment?

- 2What are the common methods of chemical surface treatment?

- 3What are the types of surface treatment technologies?

- 4What are the influencing factors of surface treatment strength?

- 5What are the functions of plastic surface treatment?

- 6Analysis of Substrate Surface Treatment to Prevent Corrosion

- 7Application of QNIX Thickness Gauge in coated Film thickness measurement

- 8Several surface treatment methods before painting metal products

- 9Fluorine Pretreatment: Application Examples