How to assess the painting surface roughness?

After blasting, the surface of the material becomes rough due to the impact and grinding action of the abrasive. In order to quantitatively describe and compare the roughness characteristics of the steel surface after spray derusting and other mechanical processing operations, many countries have successively formulated surface roughness standards, such as German standard DIN4768, Japanese standard JISB0601, etc. my country has also promulgated relevant surface roughness standards, such as GB3505, GB/T13288 and so on.

The International Organization for Standardization ISO/Tc35/sc12 has also specially formulated the international standard ISO8503, which is used to evaluate the roughness of the steel surface after spray derusting. The standard consists of four parts:

ISO8503-1 The technical requirements and definitions of ISO surface roughness comparison samples;

ISO8503-2 Classification of surface roughness of steel after blast cleaning—comparison sample method;

ISO8503-3 ISO reference block calibration and surface roughness measurement method - Microscope focusing method;

ISO8503-4ISO reference block calibration and surface roughness measurement method - angle needle method.

Referring to ISO8503, my country has formulated the corresponding national standard GB/T13288 "Assessment of surface roughness grade of steel before painting (comparison sample method)". This section will give a brief introduction to the main content of the standard.

(1) Surface roughness benchmark comparison sample block

The surface of steel after jet abrasive cleaning will form irregular convex and concave features that are difficult to describe. There is no method to accurately measure the roughness value of this surface. Therefore, my country's national standard and international standard ISO8503-2 are used to judge the roughness of the blast-cleaned surface by comparing it with the surface roughness benchmark comparison sample in an intuitive or angular way.

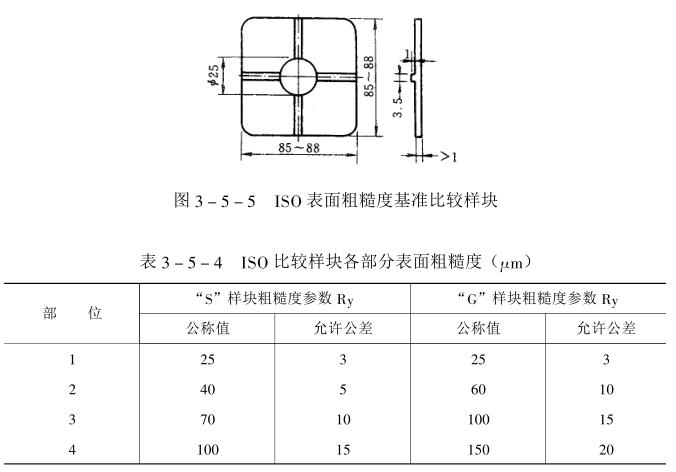

The ISO surface roughness benchmark comparison block is a block divided into four parts, each with a specified benchmark

Flat plate with surface roughness. Its dimensions are shown in Figure 3_5_5.

The roughness value of the ISO surface roughness reference sample block needs to meet the requirements of Table 3_5_4, and its intuitive surface cleanliness should not be lower than sa2j level. The samples reflecting the surface roughness characteristics obtained by jetting angular sand abrasives (GRIT) are called "G" samples; the samples reflecting the surface roughness characteristics obtained by blasting shot abrasives (sHoT) are called "s" samples .

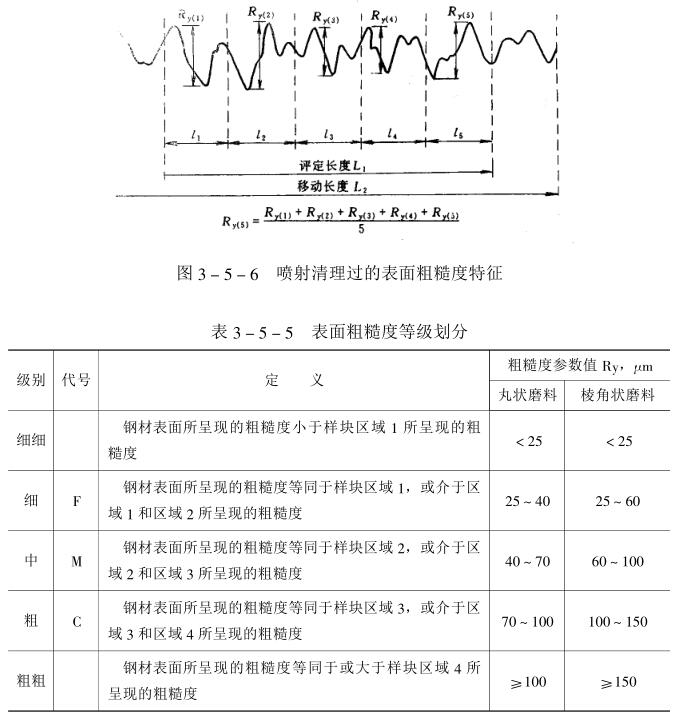

The "roughness parameter Ry" in the table is the roughness parameter measured by the angle needle method according to ISO8503-4. Peak_valley height". Their definitions are shown in Figure 3_5_6.

The ISO sample block is made of iron or other corrosion-resistant metals, and the blast-cleaned low-carbon steel surface is used as the prototype, and it is processed by the forming male mold method. Such samples shall be checked routinely, and the cycle shall not exceed six months.

(2) Surface roughness grade

The standard divides the roughness formed by spray cleaning the steel surface before painting into three grades: "fine grade", "medium grade" and "coarse grade". The roughness lower than the "fine level" is called "fine level", and the level higher than "coarse level" is called "coarse" level. This extension level is generally not used in industry. The classification of surface roughness is listed in Table 3_5_5.

The three grades of F, M, and C are sufficient to meet the requirements for surface characteristics of coatings.

(3) Evaluation method of surface roughness

The steps to evaluate the surface roughness are: first remove the floating ash and stone debris on the surface of the steel to be tested, and then select the appropriate surface roughness comparison sample ("G" sample or s "sample block), compare it with a certain area of the surface to be tested, and then visually compare the surface to be tested with the four parts on the sample block, and observe with a magnifying glass with a magnification of no more than 7 times if necessary, to determine Compare the two parts of the sample block that are higher than and lower than the roughness of the measured surface, and the roughness grade of the measured surface can be obtained according to Table 3_5_5. To make a correct evaluation of the surface roughness, the method is to use the back of the nail or a wooden angled needle sandwiched between the thumb and forefinger to scratch alternately on the surface to be tested and the surface of the sample, and determine the surface roughness level according to the angle. ,, Since the above-mentioned standard measurement methods have not yet been popularized, many design and construction departments still use traditional methods to measure surface roughness, such as using a roughness measuring instrument with a probe and a dial indicator. It is said that this measurement method still has certain practical value at present.

- 1Influence of surface roughness of parts

- 2High-precision roughness instrument measures the surface roughness of plastic materials Case sharing [Video demonstration]

- 3How to measure concrete surface profile (roughness) quantitatively

Defelsko

- 4Evaluation of steel surface roughness

- 5The relationship between abrasive and surface roughness

- 6Surface roughness of metal

- 7Roughness and Surface Roughness

- 8Which industries need to use surface roughness meters?

- 9Surface roughness measurement

-

-

-

Defelsko positector SPG1 Roughometer$ 890.00

-

-

-