Roller painting tools and methods

Roller coating is a coating method that uses a roller to pick up paint and roll it on the surface of the workpiece. It is generally divided into two types: manual roller coating and mechanical roller coating, which are suitable for the coating of flat equipment.

The construction method of roller coating is suitable for the coating of larger surfaces, and the construction efficiency is lower than that of spray coating, but 2~3 times higher than that of brush coating. The paint waste of roller coating is also less, no paint dust is formed, and the pollution to the environment is small. One of the outstanding advantages of roller coating construction is that a longer support rod can be connected to the rear of the roller, and the operation can be carried out at a longer distance during construction, which reduces the trouble of building scaffolding. Similar to brushing, it also has strong penetrating power for the formation of paint film. But for the coating surface with complex structure and unevenness, the roller coating method is limited, the painted film surface is not smooth, and the efficiency is not as high as that of spraying and other methods.

(1) Commonly used roller coating tools

The tool used for roller coating is a roller. The roller is a hollow cylinder with a small diameter, and the surface layer is covered with plush made of wool or synthetic fibers. The roller is composed of a roller body and a roller sleeve. The roller sleeve can be loaded and unloaded freely, which is equivalent to the paint brush part.

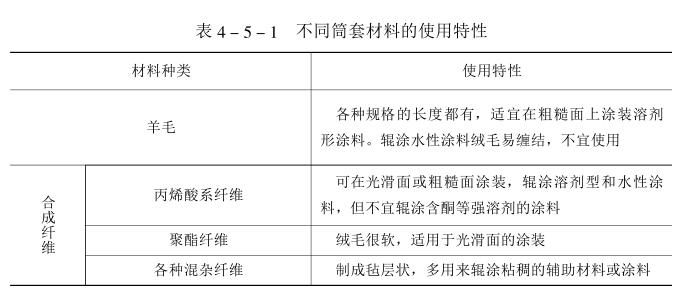

There are many types and specifications of rollers, and the selection should be adapted to the condition of the painted surface and the type of paint, mainly from three aspects: the width of the roller, the length of the fluff of the roller sleeve and the material of the sleeve. The width of the roller is generally 18cm and 23cm, and the standard diameter is 4cm. If the diameter is increased to 6cm, the amount of paint dipped in it can be increased by 50%. Large-width rollers can be used to paint large areas of objects such as workshops and walls; small-width rollers are used to paint door frames, treads and card edges, etc. In addition to ordinary shaped rollers, there are also various special-shaped rollers, which can form different patterns and shapes. The fluff length of the roller sleeve is generally 4.5~40mm, and there are three specifications of short, medium and long, which have a certain influence on the performance of the roller. The short hair absorbs less paint, and the texture produced is fine and shallow, and can be rolled onto a smooth surface. The medium and long-pile rollers can absorb a lot of paint, and can be used on ordinary and rough surfaces. The long-pile roller is most suitable for rough surfaces such as masonry surfaces and iron mesh. Commonly used sleeve materials are wool and synthetic fibers (see Table 4_5_1).

(2) The construction method of the roller

(1) New rollers should be cleaned repeatedly before use and the rollers should be moved to remove residual hair and dust. Depending on the height of the object to be painted, install a wooden stick of appropriate length under the handle, etc., so as to paint with a longer distance.

(2) Clean the roller with diluent before coating the roller or soak the roller, roll off the excess thinner on the waste paper and then dip in the paint.

(3) Dip 1/3 or half of the roller into the paint, and then roll back and forth on the plate surface of the container several times to make the roller soak in the paint.

(4) Gently roll the roller in a w-shape to roughly distribute the paint on the surface of the object to be coated. When painting on the working surface, first roll the paint in the horizontal direction, and as the paint on the roller decreases, the rolling speed can be appropriately accelerated. After the paint on the roller is basically used up, roll it vertically to level the paint with uneven thickness until it is evenly coated. During the last coating, the roller should be rolled in a certain direction, and then modified after rolling.

(5) If the used roller needs to be reused for a short time, it does not need to be cleaned, just soak it in thinner, clean water or one-component paint with low viscosity; when it is used again, squeeze out the excess thinner, moisture or paint. When a project is completed, it must be cleaned effectively until the true color of the fluff is exposed, cleaned and dried, and the fluff and hair on the sleeve are loosened to prevent the fluff from tangling with each other during storage. When storing, the sleeve can be wrapped in kraft paper.

(6) When applying roller coating, the initial force should be light to prevent the paint from overflowing and flowing; as the amount of paint decreases, gradually increase the force.

(7) After the construction is completed, scrape off the excess paint with wood chips for cleaning and storage.

- 1What are the construction skills and mass control points for roller painting construction?

- 2Overview of roller painting

- 3How to choose the right Spreader method?

- 4Advantages and disadvantages of roller painting method

- 5Why analyze roller painting flowability?

- 6Spreader method of roller painting flow classification

- 7Roller painting method

郑顺兴 - 《涂料与图纸科学技术基础》

- 8What are the advantages and disadvantages of using roller painting method

- 9Coating Spreader Process Introduction A roller painting