Summary of high pressure airless spraying tools and construction methods

High-pressure airless spraying is to make the paint pressurized by a booster pump (0.14~0.69MPa), and sprayed out through a special hard alloy nozzle (0.17~1.8mm), and its speed is very high. When the high-pressure paint flow and the high-opening nozzle reach the atmosphere, with the sharp drop of the impact air and high pressure, the solvent in the paint expands violently and disperses and atomizes, and is coated on the object to be coated at a high speed. Because the atomization of paint does not use compressed air, it is called airless spraying. It uses high pressure to generate atomization, so it is also called high-pressure airless spraying.

The advantages of this construction method are: the production efficiency of high-pressure airless spraying can be increased by several to ten times compared with general spraying; The pollution of paint mist improves the working conditions; it can realize the spraying of high solid content and high viscosity paint, and form a thicker coating film at one time; reduce the number of construction times and shorten the construction period. Since there is no air in the paint flow, the paint film defects caused by impurities such as moisture, oil, and dust in the compressed air are eliminated. The coating film has good adhesion, and a good paint film can be formed even in the gaps and corners.

A shortcoming of this kind of construction method is: the amplitude of the spray and the amount of ejection cannot be adjusted during operation, and the purpose of adjustment needs to be replaced by replacing the nozzle. Not suitable for thin layer decorative coating. The speed of painting is very high, and certain protective measures are required.

With the development of the paint industry, high-pressure airless spraying, as a relatively common construction method, has the advantages of high efficiency, wide application, and can be sprayed once to form a film. It will have a broader application prospect.

(1) Equipment and tools for high-pressure airless spraying

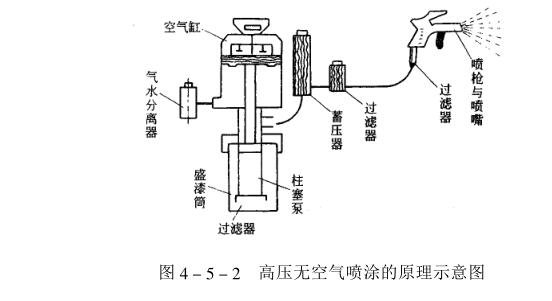

The equipment for high-pressure airless spraying mainly includes: booster pump and Spray Gun. In addition, there are pressure accumulators, paint filters, high-pressure hoses, etc. The more critical equipment is the Spray Gun. The schematic diagram of the principle of high-pressure airless spraying is shown in Figure 4_5_2.

Its main equipment are:

①Spray gun: form the paint into mist and spray it on the surface of the object to be coated;

②Boosting pump: provide high pressure, so that the paint can be sprayed out at a high speed;

③Pressure accumulator: stabilize the hydraulic pressure of the coating and reduce the pressure fluctuation during spraying:

④Paint filter, filter: filter paint, reduce paint road blockage;

⑤ High-pressure hoses, conveying paint, resistant to paint erosion and high pressure.

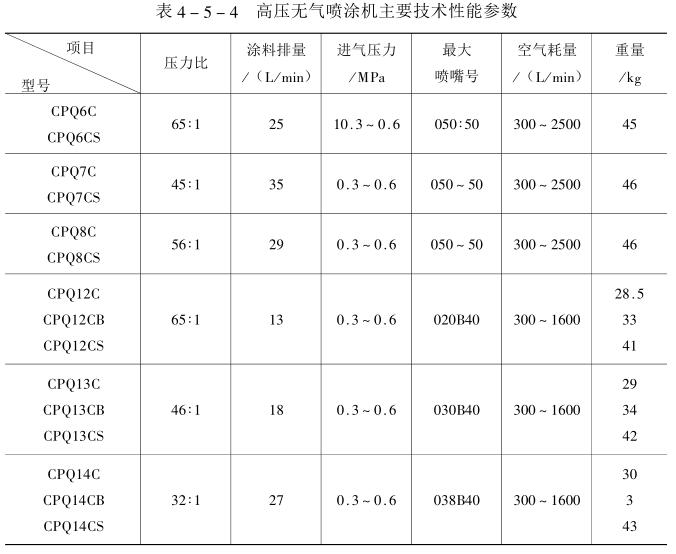

High-pressure airless spraying devices are classified according to the driving force: pneumatic type, electric type, and internal combustion type. Classified according to the working pressure of the medium to be sprayed: low pressure type (<10MPa), medium pressure type (10~20MPa), high pressure type (20~30MPa), ultra-high pressure type (30~40MPa). Classified according to the displacement of the sprayed paint and other media: small (<5L/min), medium (5~15L/min), large (15~25L/min), super large (>25L/min), spraying equipment should be in _15~50℃ ambient temperature, and the relative air humidity is not more than 85%. At present, the main construction units mostly use pneumatic high-pressure airless spraying equipment, using compressed air to drive the pump, and adjusting the air pressure through the pressure reducing valve. Pressure is used to control the output pressure of the paint. According to the design of the pump, the paint pressure can reach several tens of times the input air pressure. The ratio of the paint pressure to the air pressure is called the pressure ratio. :1, 45:1, 56:1, 65:1, etc., which are suitable for coatings of different materials and viscosities. Sichuan Changjiang Machinery Factory is a professional coating equipment factory with a large scale and a large output in CHINA. It produces various There are more than 40 kinds of high-pressure airless spraying machines, and Table 4_5_4 shows the main technical performance parameters of high-pressure airless spraying machines.

Spray gun is the main tool of high-pressure airless spraying method, which is composed of gun body, nozzle, filter screen and connecting parts. It is required to be able to withstand the high pressure of 50MPa, resist the action of various media, have good sealing and wear resistance, and not leak high-pressure paint; the gun should be flexible, and the spraying or cutting of the paint flow can be completed instantaneously; there is a safety device, After the safety device is locked, pull the trigger of the Spray Gun, and the Spray Gun should not be opened.

When using high-pressure airless spraying, the following issues should be paid attention to:

(1) Spraying pressure and flow rate: For a certain type of airless spraying equipment, when the viscosity of the paint used is constant and the input compressed air pressure is constant, the relationship between the spraying pressure and the flow rate is: the flow rate increases, and the spraying rate increases. Reduced pressure. When the pressure of the input compressed air increases, the spraying pressure and flow will increase accordingly.

(2)涂料粘度与喷涂压力:不同类型的涂料粘度不同,高固体分涂料的粘度尤其大。粘度越高,施工时需要的喷涂压力越大。各种涂料的施工说明书上都注明了涂料的粘度和无气喷涂施工所需的压力比。一般低粘度涂料的压力比选择23:1、32:1,而高固体分涂料的施工压力比一般在45:1左右。但不能一味增加喷涂的压力,因为随着压力的增大,喷嘴的磨损也逐渐加快,应考虑更换大口径的喷嘴。

(3)喷嘴的选择,在进行高压无气喷涂前,According to所使用的涂料和喷涂对象,应选择一定孔径和形状的喷嘴。喷嘴的孔径决定了流量的大小,喷嘴的形状则决定了喷雾的幅度。对于粘度较高、所需施工面积较大的涂料,应选择孔径较大的喷嘴。

(二)高压无气喷涂的施工方法

(1)选择适宜的喷枪及确定喷嘴大小、喷涂距高和适当的蟥徐压力。此时,应考虑泵的排量能力、喷涂材料的物理状况、被涂物件表面的形状特征以及涂膜的质量要求等。在涂料的施工说明书上有针对高压无气喷涂的施工指导,须按要求仔细选择。

(2)涂料应在喷涂之前,准备妥当。双组分涂料应混合均匀,同时有一定的活化期。涂料需经过滤、去掉漆皮等杂质处理。涂料的粘度一般不需用稀释剂调整,若需调整时,严格按产品说明书要求量(一般小于涂料用量的5%)。

(3)喷流的喷射角度为30°~80°,喷流的幅度有8~75cm宽。在喷涂大平面时,选定喷流幅度为30~40cm;涂装物件较大、且有凹凸表面的大量涂装,选用20~30cm;喷涂一般小物件,选用15~25cm。当可获得所要求的雾化效果时,使用最低的喷涂压力,可延长喷嘴的使用寿命。

(4)喷枪应与被喷工件表面垂直,距表面30~40cm。喷枪应以合适的速度均匀移动,并与工件表面平行,以免产生流挂和涂层不匀。喷枪与物面的喷射距高和垂直角度由身体控制,喷枪的移动同样要用身体来协助臂膀的移动,不可移动手月宛,但手月宛要灵活。

(5)每一道喷漆作业就在前一道喷漆作业上搭接约5o%,以便获得完整、均匀的涂层。作业时应从右到左,然后从左到右。

喷;拐角时,喷枪可对准;拐角的中心,以确保两側能得到均匀的喷涂。

(6) During operation, attention should be paid to the coordination among the Spray Gun, hose and body. When the operator stands and operates, the feet are slightly wider than the shoulders, and the hose is held in one hand. The hose should not be stretched too tightly, which will help the Spray Gun to move easily.

Hold the gun with your hand, but not too tightly, and use your index and middle fingers to pull the trigger.

(7) After spraying, pour the excess paint back into the original paint bucket, then clean the Spray Gun, do not allow residual paint in the Spray Gun, spray thinner to clean the pipe and the inside of the Spray Gun. Then completely release the pressure, disassemble the nozzle and the sheath one by one, remove the nozzle first, and wipe it clean with solvent. When cleaning, use a soft brush with solvent to carefully clean the nozzle and gun body. When the air hole is blocked, it needs to be cleared with a cork needle, and hard tools must not be used to remove the sundries in the nozzle.

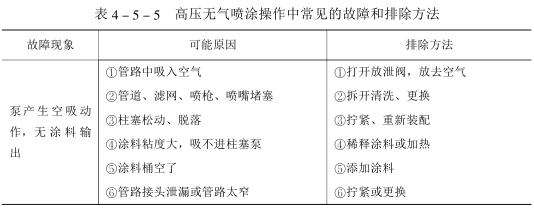

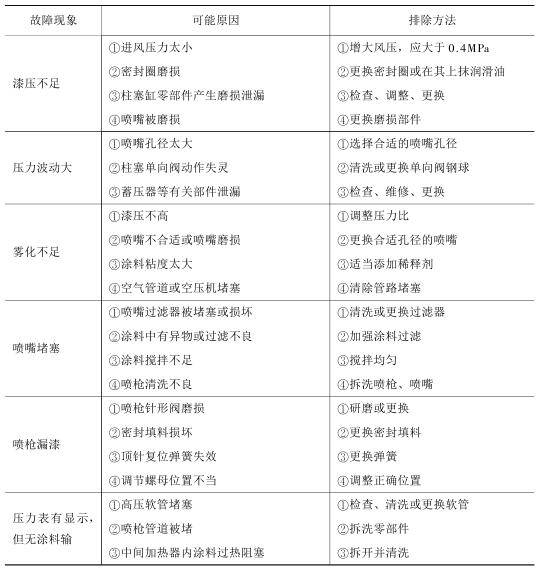

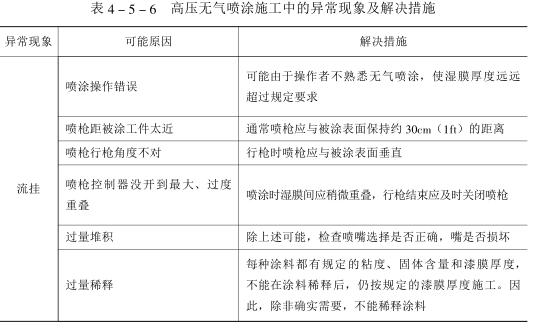

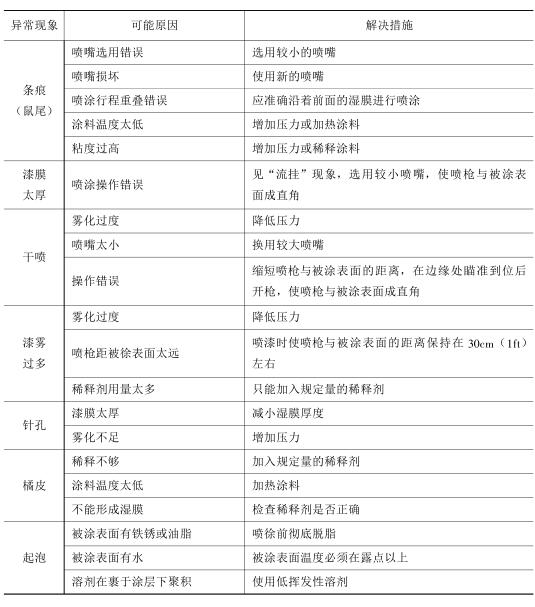

(8) Common faults and troubleshooting methods in high-pressure airless spraying operations are shown in Table 4_5_5.

When spraying, move horizontally first, and then move vertically, which is beneficial to the complete coverage of the coating and reduces sagging.

When spraying each time, the Spray Gun trigger should be turned on when the Spray Gun is moving, and the Spray Gun trigger should also be turned off when the Spray Gun is moving, so as to avoid excessive paint accumulation and sagging on the surface of the workpiece.

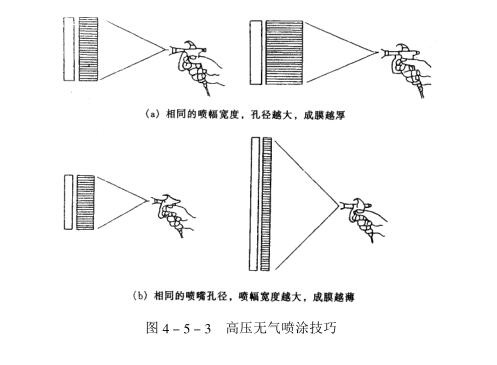

The same spray width, the larger the aperture, the thicker the film (see Figure 4_5_3a).

For the same nozzle aperture, the larger the spray width, the thinner the film (see Figure 4_5_3b).

- 1The principle and common equipment of airspraying method

- 2Three lame plating methods for fluorocarbon paint painting

- 3High pressure airless lame plating

- 4What is airspraying?

- 5Regulation and maintenance of lame plating equipment

- 6Lame plating technology

- 7How to choose car lame plating equipment?

- 8Application of Miscellaneous lame plating technology in medium coating and topcoat

- 9Principles for choosing a lame plating process