Introduction of self-swimming paint coating process

Compared with electrophoretic coating, the process of self-coating is relatively simple, and the pre-treatment does not require surface adjustment and phosphating treatment, and self-coating liquid does not require ultrafiltration. The process is generally: pre-degreasing → degreasing → hot water washing → water washing → rust removal → water washing (two steps) → pure water washing → self-swimming → water washing → post-treatment → curing. The pre-degreasing and degreasing process mainly removes the oil, stains, impurities, etc. attached to the surface of the process; then removes the rust, oxides, etc. on the surface of the workpiece through the derusting process; Self-foaming paint tank solution; self-foaming process is an important step in the coating process, through chemical reactions, the paint film is formed, and the film thickness is mainly controlled by time, temperature, solid content, etc.; post-treatment improves the performance of the paint film through passivation; curing The process evaporates the water in the wet film, makes the paint film polymerize, and forms a uniform, dense and smooth coating. It should be pointed out that the time interval between the post-swimming treatment and the drying stage should be shortened as much as possible, generally controlled at 5-10 minutes.

The film-forming process of self-swimming emulsion is special. Autophoretic deposition of coating film at room temperature is only the result of mutual cohesion of spherical colloidal particles. There are countless gaps between the colloidal particles. After exceeding a certain temperature (ie MFT), colloidal particles and colloidal particles are required to fuse and finally solidify to form a film. Therefore, the MFT of self-swimming emulsion is an important parameter. If the MFT is too high, the colloidal particles cannot be fully fused, and the formed coating film will have pinholes, and its corrosion resistance will inevitably be poor; if the MFT is too low, although the fusion between the colloidal particles is good, it is easy to obtain defect-free coatings. However, since the reduction of the MFT of the latex is at the cost of reducing its relative molecular mass, the glass transition temperature Tg of the latex is reduced, and the corrosion resistance of the coating film is usually reduced. In order to solve this contradiction, the use of emulsion gradient polymerization technology is an effective way, that is, at different stages of emulsion polymerization, monomers with different properties are used to make the colloidal particles have core-shell structures with different properties, and the shell layer has a lower MFT, while the rubber core has a higher Tg, forming a "soft shell and hard core" structure, so that the lower MFT shell is conducive to the fusion of the colloidal particles, and the higher Tg rubber core makes the coating body have a higher The relative molecular mass, thereby improving the corrosion resistance of the coating.

When the workpiece is taken out of the dipping solution, the water content of the coating can reach 60%~70%. However, since the latex resin has been solidified, it can be washed with water. After washing with water, it can be washed with chromic acid aqueous solution and baked at a specific temperature (such as 150~160°C for acrylic resin) to obtain a coating with better performance.

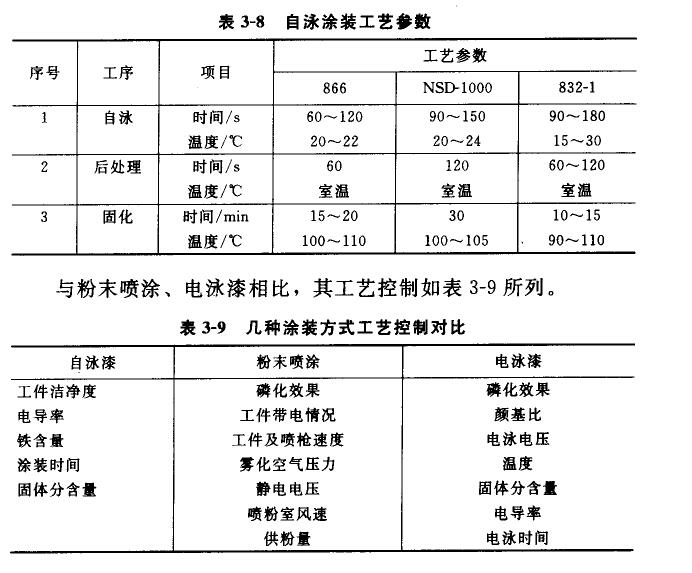

There are certain differences in the process parameters of different self-coating paints. Table 3-8 lists three self-coating process parameters for reference.

In the control and management of the coating process, it is necessary to control the solid content, and check the pH value and conductivity of the pure water washing tank, so that the conductivity of the water dripping from the workpiece into the self-coating tank is less than 50µS/cm, preventing Bring in impurities. The tank temperature must be strictly controlled. If the constant temperature is too low, the reaction speed will be reduced and the thickness of the paint film will be thinned; if the temperature is too high, the stability of the self-coating paint solution will be destroyed. The change of conductivity in the self-coating tank can reflect the pollution degree of the tank and the content of iron ions, and the normal value should be less than 4500µS/cm. During the coating process, it is also necessary to monitor the redox potential, fluoride ion concentration, and iron ion concentration in real time, and to adjust the redox potential and its concentration by adding FeF3, H2O2 and other oxidants in time to ensure the stability of the bath.

Self-coating equipment is mainly composed of pre-treatment tank, washing tank, self-foaming tank, post-treatment tank, conveying equipment and drying furnace. For self-coating tanks and production line tanks, process design and non-standard equipment design should be carried out according to the coating product structure, production program, and workshop conditions. It should be pointed out that when designing an automatic production line, in order to shorten the interval between post-processing and drying stages, it is not appropriate to use ordinary hanging conveyors, but to use product-free hanging machines and use computer programs to control them.