QHQ-A Portable Pencil Scratch Tester Instruction Manual

| brand | Jingke | model | QHQ-A |

| product name | Pencil scratch Tester | experiment method | GB/T6739-86, JISK5401, ASTMD2197 |

1. Purpose

Coating film hardness is a necessary indicator for quality certification in the coating manufacturing and coating application (coating surface) industries. The pencil scratch method to test the hardness of the coating film has been widely used in the world since the 1980s. Our country has also promoted this test method in the development research and industrial production of coatings. This instrument is designed and manufactured according to the manual operation method in Article 23 of the national standard "Pencil Test Method for Coating Film Hardness" "GB/T6739--1996". The instrument can be used in the laboratory or on the construction site, and can test the hardness of the coating film in any direction.

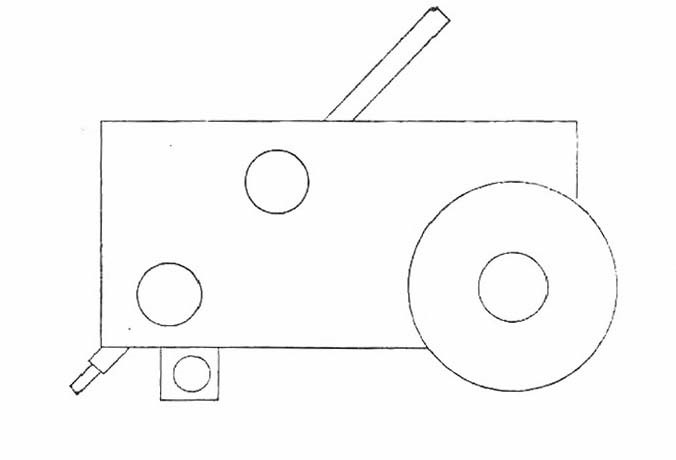

2. Structure and working principle

The instrument is mechanical, and three points touch the surface to be tested (two points are the wheel, and one point is the lead core) to always ensure that the pencil forms a 45° angle with the surface to be tested, which is used to push the instrument to move, and the test process can be completed.

3. Requirements for use

1. GB1279---79, {general preparation method of paint film} prepare three inspection pieces, usually smooth tinplate plate 120*50*(0.2—0.3) mm, or the substrate size specified by the product.

2. Experimental conditions: according to product standards or construction requirements.

4. How to use

1. Preparation; use a pencil sharpener to sharpen the pencil to expose the cylindrical lead 5---6MM (do not loosen or cut the refill) hold the refill so that it is clamped at 90° with the "No:400" sandpaper surface , and keep drawing circles on the sandpaper until the lead with a sharp edge is rubbed on the end of the refill (the edge must not be broken or notched). After each use, the pencil should be rotated 180° before use, or re-grind before use.

2. Operation: Put the instrument on a flat workbench, place the block on the lower part of the instrument, insert the sharpened pencil into the main hole of the instrument, and tighten the screw when the edge of the pencil touches the workbench.

3. Put the instrument on the board to be tested, and push it forward at a speed of about 1mm per second with force (this force may break the edge of the lead core or plow the film). Starting from the hardest pencil, plow five 3mm-long traces with each level of pencil until a pencil that does not plow the coating film is found. The hardness of this pencil represents the pencil hardness of the measured coating film.

Five, matching

Each instrument is equipped with a pad, and a set of Zhonghua brand high-grade drawing pencils (6H--6B).

NOTE: Pencils can be purchased locally when they run out.

- 1Hardness testing for hard film applications

Carestream Tollcoating

- 2How to test the scratch resistance of coats

Tom Mastrangelo

- 3Modern environment HY-IV type, scratch Tester operating instructions

- 4Modern environment ZHY type, automatic Scratch meter operating instructions

- 5Film Hardness performance test summary

- 6Pencil Hardness Tester in Adhesive primer performance research

- 7Hardness of films measured by scratch method

- 8Pencil Hardness Tester measurement Eletroplating tin plate surface scratch resistance

- 9Pencil Hardness Tester in powder finishing film performance