Film thickness measurement for polyurea coating with Defelsko Thickness Gauge

The original purpose of measuring coating thickness is to determine the appropriate coating thickness range while controlling costs. Commercial contracts often require independent inspection of the work upon completion. Due to the widespread use of polyurea coatings and liners in containment systems, ensuring proper thickness is essential.

Destructive thickness measurements are commonly used to test coating thickness on substrates such as concrete and steel. But the stretchy and/or elastic nature of thicker polyurea coatings can make it difficult to draw clean lines and result in inconsistent test readings. The requirement to test areas for repair before the structure can be returned for overhaul further disadvantages this approach.

ASTM D6132 and D7091 standards specify a non-destructive testing method that eliminates the need for coating repair after inspection, and both save inspectors and contractors time and money. Non-destructive testing methods include magnetic and eddy current Thickness Gauges for measuring metallic substrates, and ultrasonic Thickness Gauges for testing non-metallic substrates such as concrete.

The non-destructive measurement of the thickness of polyurea coatings on metal substrates is a simple procedure provided the Thickness Gauge used has a measuring range appropriate for the expected thickness. Polyurea coatings can be measured by adding together multiple individual coatings to achieve the desired total thickness (through its fast-fixing performance computer-aided technique), so it is necessary to detect the thickness of individual coatings. If the polyurea coating is measured in accordance with the requirements of SSPC-PA2 and PA9, the thickness of each individual coat needs to meet the parameters of the project, whether it is applied to concrete or metal substrates.

metal substrate

The PosiTector 6000 Series Coating Thickness Gauge is designed for simple operation and is ideal for testing polyurea coatings on magnetic and non-magnetic metal substrates.

● 6000 FT/FTS - polyurea coatings on steel up to 6 mm (250 mils) thick

● 6000 FNTS - Polyurea coatings up to 6 mm (250 mils) thick on magnetic and non-magnetic metals

● 6000 FKS - polyurea coatings on steel up to 500 mils (13 mm) thick

● 6000 NKS - Polyurea coatings up to 500 mils (13 mm) thick on non-magnetic metals

● 6000 FLS - polyurea coating on steel up to 38 mm (1.5") thick

● 6000 FNGS - polyurea coatings up to 63.5 mm (2.5") thick on magnetic and non-magnetic metals

concrete substrate

Since magnetic and eddy current Thickness Gauges cannot test polyurea coatings on ferrous substrates, ultrasonic Thickness Gauges are used. Ultrasonic measuring instruments, such as the PosiTector 200 D, send ultrasonic pulses to the coating surface through a probe with a couplant (i.e. a transducer). Simply put, it is the propagation time for the ultrasonic signal to pass through the coating to the substrate interface and reflect back from the substrate to determine the thickness of the coating.

The PosiTector 200 D-Series Coating Thickness Gauge is specifically designed to test very thick, elastic and acoustically attenuating coatings, including polyurea. The PosiTector 200 D advanced model features the ability to measure the thickness of up to three individual layers of polyurea coating systems and a simple readout. Concrete substrates tend to have a higher surface profile than metals and can exhibit varying degrees of porosity, which can cause measured thickness values to vary significantly depending on where the probe is placed. In such cases, the average method should be used to determine the total thickness of the coating.

The PosiTector 200 D Series Coating Thickness Gauge uses proven ultrasonic technology to test polyurea coatings on concrete, wood and other non-metallic substrates in the coating thickness range of 50 to 5000 microns (2 to 200 mils).

The PosiTector 200 D1 (standard version) measures the total thickness of polyurea coating systems.

The PosiTector 200 D3 (Advanced version) measures the total thickness of a polyurea coating system or up to three individual coats and outputs a graphical diagram that facilitates detailed analysis of the coating system. Minimum individual polyurea layer thickness is 500 microns (20 mils).

Due to the difficulty of measuring polyurea coating systems applied to multiple channels, the advanced version of the PosiTector 200D series is recommended. When used with the PosiTector 200 probe, the advanced model provides an intuitive graph of the ultrasonic pulses as they pass through the coating system. This visual display greatly simplifies the process of adjusting the gage (if required) and increases the confidence of the operator in presenting measured thickness data.

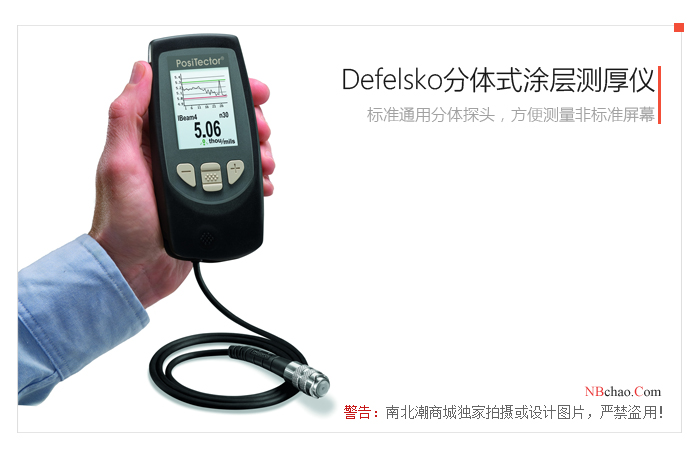

The following pictures are the display pictures of Positector6000 series Thickness Gauge and PosiTector 200 series Thickness Gauge respectively: