Huayang HCC-25 Eddy Current Thickness Gauge Operation Instructions

1 Overview

Huayang HCC-25 eddy current Thickness Gauge is a coating thickness measuring instrument that works by eddy current method. The design of the instrument complies with the following standards: ISO2360 and GB4957.

The difference from another product of our company, the HCC-24 coating Thickness Gauge, is that this product

It is suitable for measuring the thickness of the non-conductive coating on the non-magnetic metal substrate, for example: measuring the thickness of the anodic oxidation layer of aluminum and the paint, plastic spraying and rubber coating on the surface of aluminum, copper, zinc and other materials. It has been widely used in light industry, machinery, instrumentation, chemical industry and other industries.

This instrument is an intelligent instrument. Due to the application of professional wear-resistant guide sleeve measuring probe and single-chip microcomputer, it has more remarkable features, such as small measurement error, high reliability, good stability, easy operation, small size, and strong data processing function etc., are the testing instruments needed to control and guarantee product quality.

2 Technical parameters

1) Measuring range: 0~1200μm.

2) Measurement accuracy: ±(1~3%H+1μm).

3) Resolution: 1μm.

4) Minimum measuring surface diameter: φ10mm.

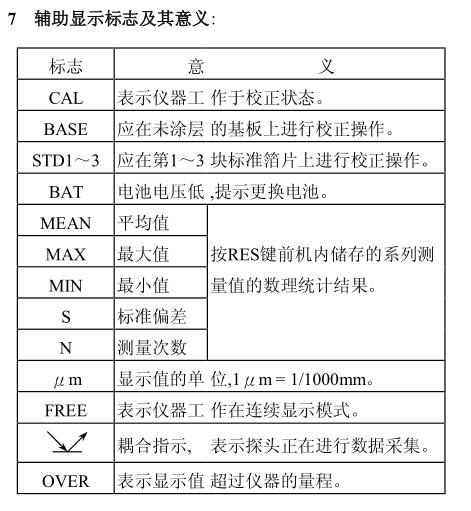

5) Display: 4-digit LCD displays the measured average value, maximum value,

Minimum value, standard deviation and number of measurements, while referring to

Indicates the working status of the instrument and battery usage.

6) Power supply: one 6F22 9V battery.

7) Dimensions: 160mm×80mm×30mm.

8) Mass: about 250g.

9) Operating environment: temperature 0℃~40℃;

The relative humidity is not more than 90%.

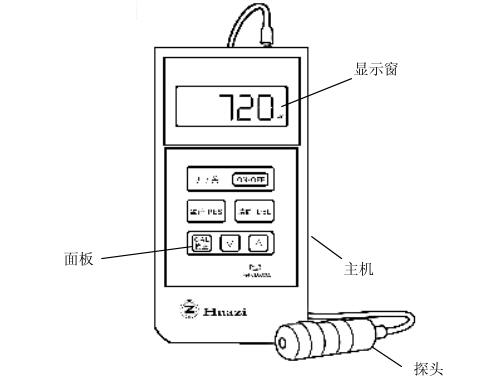

3 Appearance of the instrument

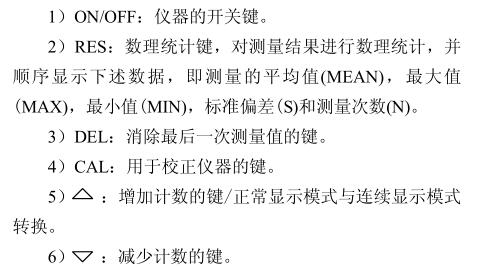

4 Key function description

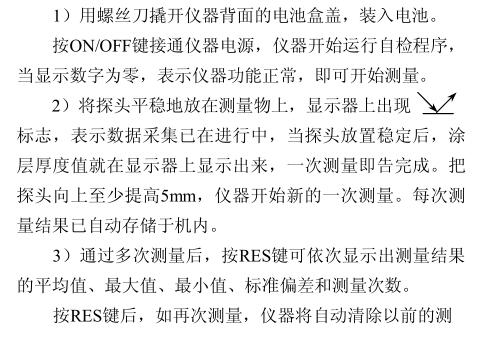

5 Basic operation method

value, and store the new measured value.

4) If during the measurement, due to the unstable placement of the probe, an obviously wrong measurement value is displayed, you can press the DEL key to eliminate the measurement value, so as not to affect the accuracy of the statistical results. If the instrument fails to collect data due to the probe being lifted off too quickly, the displayed value will be zero, and the zero displayed at this time will not affect the final statistical result.

5) After using the instrument, press the ON/OFF key to turn off the power. The instrument

The device has an automatic shutdown function, if no operation is performed, it will automatically shut down after about five minutes.

6) The instrument has a power status indication function. When the power supply voltage is insufficient, "BAT" will be displayed on the upper left corner of the display. After that, although the instrument can still work for about two hours, it is recommended that the user should replace the battery at this time. When the battery voltage is too low, the instrument will automatically power off.

7) In addition to the above conventional working modes, the instrument also has a continuous display

display mode. In the normal working mode, press the △ key to enter the continuous display mode, and the "FREE" sign appears on the upper right corner of the display. In this state, the measured value is not stored, and the probe does not need to be lifted from the measured object after each measurement is completed, and the measurement and display continue. In this way, the continuous change of the measured value can be observed by moving the probe on the surface of the measured object.

6 Calibration method

Calibration requires three calibrated standard thickness foils and a base plate . The circular substrate supplied with the instrument is only used for testing the machine. In actual measurement, the uncoated (plated) test piece should be directly used as the calibration substrate, or the coating on the painted (plated) test piece should be ground. Go, the surface of the substrate should be flat and smooth . Calibration operations are carried out in the order shown in the table.

8 Routine maintenance of the instrument

1) After the instrument is used, it should be placed in a clean and dry storage box to avoid shock and vibration.

2) The probe should avoid knocking and strong vibration and keep it clean. The dirt on the measured object needs to be removed before measurement.

3) When the instrument is not used for a long time, the battery should be taken out to avoid damage to the instrument due to battery leakage.

- 1Coating Thickness Gauge: Magnetic VS Eddy Current

- 2EPK MiniTest 735 Eddy Current Thickness Gauge takes a wave of real pictures

- 3Defelsko Thickness Gauge Comparison 2 - Advanced Edition Eddy Current Thickness Gauge with Wire Probe

- 4LANDTEK CM-8820 Thickness Gauge Operating Instructions

- 5Biaozhi GM200 Coating Thickness Gauge operating instructions

- 6Huayang HCC-18A Coating Thickness Gauge operating instructions

- 7HUAYANG HCC-16P Ultrasonic Thickness Gauge Operation Instructions

- 8Huayang HCC-17 Ultrasonic Thickness Gauge Operation Instructions

- 9Huayang HCC-16 Ultrasonic Thickness Gauge Operation Instructions