Jingke NDJ-8S Digital Viscometer Operation Instructions

1. Working principle

NDJ-XS series rotary digital display viscometer (NDJ-1S, NDJ-5S, NDJ-8S) is an intelligent instrument controlled by a chip computer and capable of data collection, processing and display. The viscometer controls the stepper motor to run accurately and smoothly according to the set speed, and drives the rotor to rotate through the hairspring. When the rotor has no resistance, the rotor and the motor rotate synchronously; when the rotor is subjected to the resistance of the measured liquid, the rotation of the rotor will lag behind the motor. When the tension of the balance spring and the liquid resistance are balanced, the opening angle of the rotor lagging behind the motor is fixed. By measuring the opening angle, according to the set speed and rotor, the single-chip computer calculates the viscosity of the measured liquid and displays it on the LCD screen.

Compared with similar instruments, NDJ-XS series viscometer has the advantages of easy operation, high measurement accuracy, stable speed and wide working voltage range. It can be widely used to measure the viscosity of solvent-based adhesives, latex, biochemical products, paints, coatings, cosmetics, inks, pulp, starch, food, etc.

2. Main technical indicators

Viscosity measurement range: 10-100000mPa.S (NDJ-1S, NDJ-5S)

20-2000000 mPa.S (NDJ-8S)

Viscosity measurement accuracy: ±2% (full scale)

Viscosity measurement repeatability: ±5% (full scale)

Viscosity resolution: 1 mPa.S (with No. 0 rotor, resolution 0.1 mPa.S)

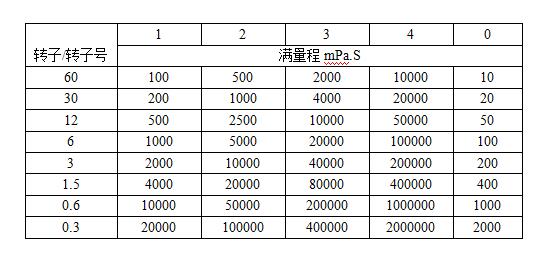

Standard rotor specifications: 1, 2, 3, 4 four (0 rotor optional)

Speed: 6, 12, 30, 60 rpm (NDJ-1S, NDJ-5S) four gears

0.3, 0.6, 1.5, 3, 6, 12, 30, 60 rpm (NDJ-8S) eight gears

Temperature measurement range: -50~99℃ (optional semiconductor temperature probe)

Temperature measurement accuracy: ±5°C

Temperature resolution: 0.1°C

Communication interface: RS232C (NDJ-5S, NDJ-8S)

Communication baud rate: 9600

Dimensions: 95*130*155 (excluding chassis)

Net weight: 2kg (excluding chassis)

Three, the use of environmental conditions

Ambient temperature: 5-35°C (recommended ambient temperature 20°C)

Relative humidity: ≤80%

Power supply: AC100~240V (50/60Hz)

There is no strong electromagnetic interference near the product, no violent vibration, no corrosive gas.

4. Instrument installation

1. Take out the chassis, lifting column and handle from the packing box. Screw the column into the chassis so that the column threads are aligned with the front, then tighten the hex nut on the bottom of the column. Install the lifting block on the lifting column and adjust the degree of tightness of the lifting.

2. Screw the handle on the lifting block, then install the main box of the instrument, and connect the temperature probe (if optional).

3. Adjust the three screws on the chassis to make the instrument level (see the level bubble on the top of the main chassis).

4. Remove the protective cap of the universal joint at the lower end of the main chassis.

5. Connect the power cord.

5. Preparation

1. Pour the liquid to be tested into a circular flat-bottomed container with a diameter of not less than 60mm.

2. Screw the protective frame of NDJ-8S digital display viscometer into the terminal under the main box reversely.

3. Select the rotor to be used, and screw it counterclockwise into the universal joint of the instrument.

4. Rotate the lifting block to slowly immerse the rotor into the measured liquid, so that the rotor liquid level mark (groove line on the rotor rod) and the measured liquid level become a plane.

5. Adjust the instrument level again.

6. The ambient temperature needs to be constant during the test to keep the displayed value stable and accurate.

6. Panel operation

Turn on the power switch on the back of the instrument to enter the waiting state. At this time, the LCD screen displays as follows:

show instructions

S: rotor, S1 means that the currently selected rotor is No. 1 (the default value at startup).

V: speed, V6 means the currently selected speed is 6 rev/min (the default value at startup).

T: temperature, T18.9 means the current temperature is 18.9°C (if the temperature probe is connected, otherwise it will display -00.0).

%: Percentage of opening angle, the percentage of the opening angle of the rotor lagging behind the motor and the opening angle of the full scale.

CP: Viscosity measurement value in mPa.S.

There are four buttons on the panel, and the functions of each button are as follows:

Rotor setting: Each time you press this key, the rotor number will increase by one, that is, 1→2→3→4→0→1, and the corresponding number will flash repeatedly.

Speed setting: Each time you press this button, the speed will increase by one gear, that is, 6→12→30→60→6 (NDJ-1S, NDJ-5S) or 6→12→30→60→0.3→0.6→1.5→3→ 6 (NDJ-8S,) The corresponding number flashes repeatedly.

Confirm: Press this key, the instrument confirms the set rotor or speed, and the number corresponding to the set position stops flashing repeatedly.

Start/Stop key: After setting the rotor and rotational speed (or the default value of power-on), press this key for the first time to start measurement, and the measured data, namely the percentage of opening angle, viscosity value and temperature value, will be displayed on the screen, and the data can be transmitted through RS232C The interface is sent to the upper PC (NDJ-5S, NDJ-8S), and each group of data is sent twice in a row; each time the key is pressed, the measurement will stop; press the key again to enter a new round of measurement.

(Note: The data transmission format is 'S*******±**.*#*P', where S is the start character, ***** is the 7-digit viscosity value (ASCII), ±**. * is the temperature value (ASCII), # is the instrument coefficient (binary), * is the cumulative checksum (binary), P is the terminator.)

The viscosity range corresponding to the combination of rotor and rotational speed can be referred to the table below:

7. Matters needing attention

1. Since viscosity is a function of temperature, when the instrument is working at room temperature, the temperature deviation should be controlled within ±0.1°C, otherwise it will affect the accuracy of measurement. A constant temperature bath is necessary.

2. Keep the rotor surface clean.

3. Since the hairspring has a certain linear area, please pay attention to the opening angle percentage when measuring. The value should be between 20% and 85%. When the opening angle percentage value is too high or too low, you should replace the rotor or change the speed. Otherwise it will affect the accuracy of measurement.

4. Be careful when loading and unloading the rotor, lift the universal joint slightly upwards, and do not use too much force. Do not force the rotor laterally and never pull the rotor down to avoid damage to the shaft tip.

5. The universal joint should be kept clean.

6. The instrument should be lowered slowly, and it is better to hold it with your hands to avoid damage to the axis due to vibration.

7. When the instrument is being transported or moved, the universal connector should be covered with a protective cap.

8. Suspensions, emulsions, polymer materials and some high-viscosity liquids belong to "non-Newtonian" liquids, and their apparent viscosity value and shear velocity have a nonlinear relationship, so use different rotors, different speeds and As the measurement time changes, the viscosity measurement value may be inconsistent, which is not due to the error of the instrument test.

- 1Rotational viscometer - principle, classification, application and calibrating

- 2Application of NDJ-8S digital Rotational Viscometer in viscosity measurement of cosmetic raw materials

- 3NDJ-5S digital Rotational Viscometer accurate measurement of natural oil viscosity

- 4Application of HBDV-1H swirl/spin High Temperature Viscometer in Viscosity Determination of Plastic Particles

- 5Rotational viscometer selection guide: How to choose the right viscosity equipment for you?

- 6Principle, type and accuracy control of Rotational Viscometer

- 7Which Viscometer to Choose for Licorice Extract Viscosity Testing? How to Test?

- 8Application of Rotational viscometer in Waterborne Polyurethane Adhesive

- 9Application of Rotational Viscometer in cellulose material