Teans TASI676 Dual-purpose Thickness Gauge Operating Instructions

Introduction

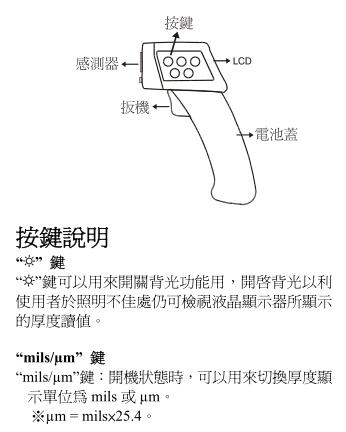

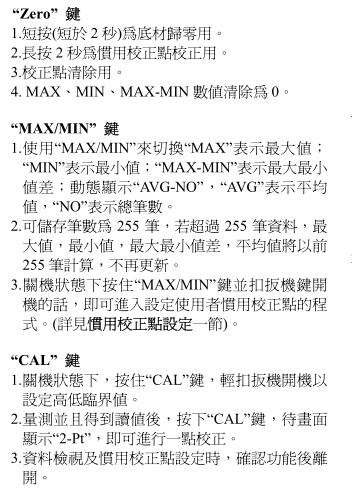

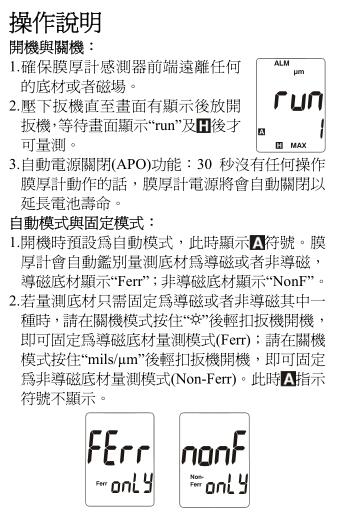

This Film Thickness Gauge is a hand-held, easy-to-use, 3½-digit (1999 reading), solid design magnetic or non-magnetic dual-purpose Film Thickness Gauge, specially designed for one-handed operation. This Film Thickness Gauge has a display backlight reading function for reading the display value in the dark, and has an automatic reading lock function and an automatic shutdown function to prolong the battery life.

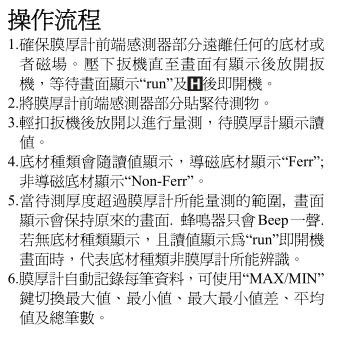

Operating Instructions

․ Before using the Film Thickness Gauge, please read the operating safety instructions and user manual.

․ Do not place the Film Thickness Gauge close to any device that generates a strong magnetic field or electrostatic field, as this may cause the Film Thickness Gauge to malfunction.

․ Do not use the Film Thickness Gauge when exposed to corrosive or flammable gases. Doing so may destroy the Film Thickness Gauge or cause an explosion.

․ Do not use . This may cause deformation of the Film Thickness Gauge or damage to the insulating layer, or cause the characteristics of the Film Thickness Gauge to exceed the specifications.

․ Do not place the Film Thickness Gauge near high temperature objects (70°C/158°F). Doing so will break the casing of the Film Thickness Gauge.

․ When the Film Thickness Gauge is exposed to significant changes in ambient temperature (hot to cold or cold to hot), please leave the Film Thickness Gauge for 30 minutes and wait for the temperature to stabilize before starting measurement.

․ If the Film Thickness Gauge continuously measures the thickness for more than 1 minute, the accuracy of the thickness measurement will decrease. However, the measurement results will still be within the specified accuracy.

․ Due to significant ambient temperature changes, the front of the sensor will condense. Please stand still for 10 minutes and start measuring after the condensation disappears.

․ The film thickness gauge , so please do not use the Film Thickness Gauge in a dusty or humid environment.

․ When measuring, be sure to confirm that the front end of the sensor is close to the object to be measured and does not shake, so as to improve the accuracy .

․ When measuring, please ensure that there are no air bubbles between the substrate and the coating.

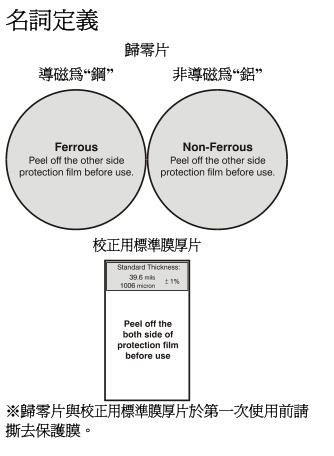

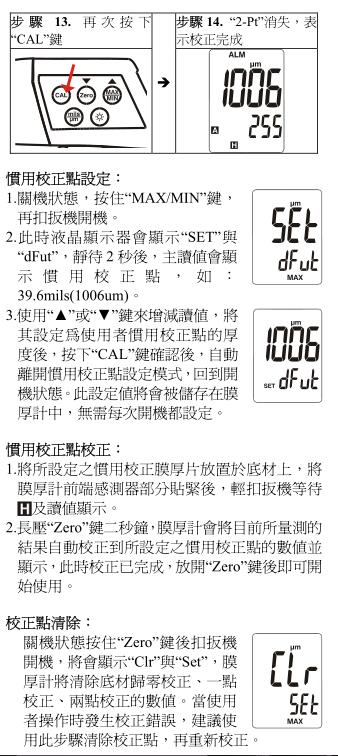

․ Substrate zero correction: This action needs to be performed every time a measurement is made.

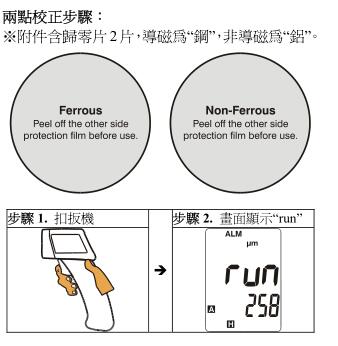

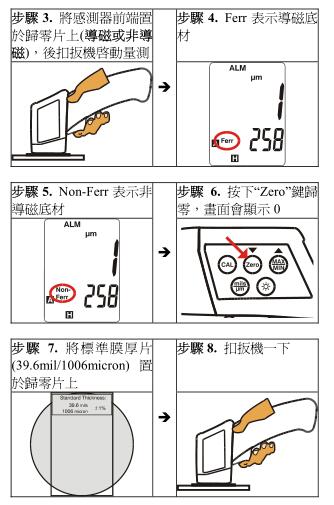

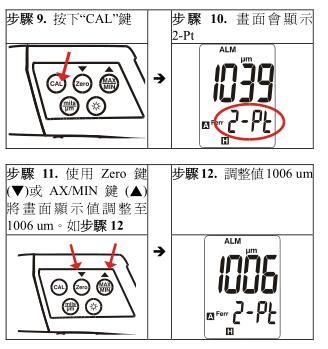

․ Two-point calibration: This action needs to be performed at commonly used test points to increase the accuracy of the measurement.

warn

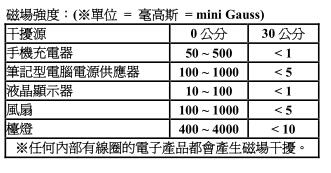

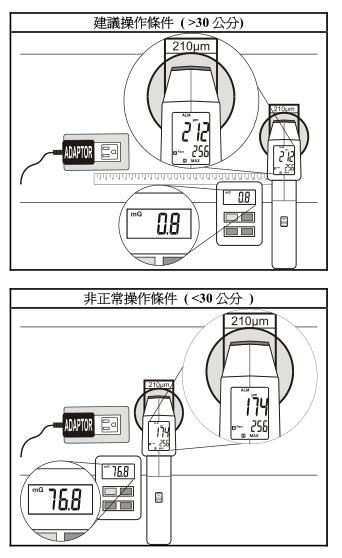

magnetic field interference

The TASI676 dual-purpose Film Thickness Gauge adopts the magnetic field measurement method to measure the coating thickness of the magnetic substrate as the base. If the Film Thickness Gauge is operated the accuracy will be affected. It is recommended to operate the Film Thickness Gauge at least 30 cm away from the source of magnetic interference.

Specification

General Specifications Display: 3½-digit liquid crystal display (LCD) with a maximum display value of 1999.

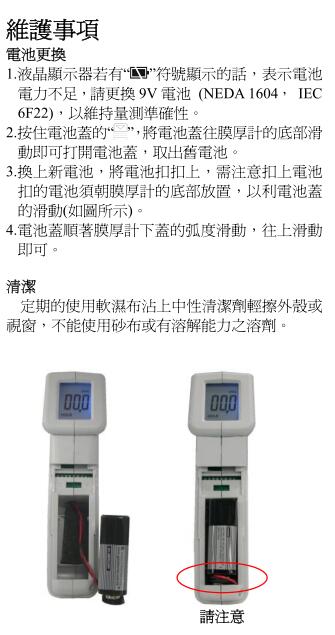

Low battery power indicator: When "  " is displayed, it means the battery power is lower than the power required for operation.

" is displayed, it means the battery power is lower than the power required for operation.

Measurement rate: 1 time/second.

Operating environment: 32°F to 122°F (0°C to 50°C), relative humidity less than 75% RH.

Storage temperature: -4°F to 140°F (-20°C to 60°C), relative humidity less than 80%RH, with the battery removed from the Film Thickness Gauge.

Automatic power off: 30 seconds.

Power consumption during standby: <15uA. Battery: standard 9V battery (NEDA 1604, IEC 6F22 006P).

Battery life: The carbon-zinc battery can be used continuously for about 9 hours ( when the display backlight is in use).

Dimensions: 14.8cm (H) x 10.5cm (W) x 4.2cm (D).

Weight: about 157 grams (including battery).

Measurable substrate types: magnetically conductive metals (iron, steel) and non-magnetically conductive metals (copper, aluminum, zinc, etc.)

Electrical Specifications

Thickness measurement range: 0 to 40.0mils (0 to 1000µm).

Display resolution: 0.1mils/1µm.

Accuracy:

±4dgts at 0 to 7.8mils

±10dgts at 0 to 199µm

±(3% + 4dgts) at 7.9mils to 40mils

±(3% + 10dgts) at 200µm to 1000µm

Temperature Coefficient: Operating ambient temperature >28°C (82.4°F) or <18°C

(64.4°F), for every increase or decrease of 1°C (°F), the specification increases by 0.1 times of the reading value .

Reaction time: 1 time/second.