Talking about powder coated Film thickness measurement and paperless technology

This article describes techniques that can be used to measure the thickness of cured and uncured powder coatings. It outlines the principles of operation and related industry testing methods and standards, and discusses new trends in paperless quality assurance (QA).

I. Overview

Film thickness measurement should be a routine job for all powder coaters (Figure 1). Regular measurements help control material costs, manage coating efficiency, and maintain surface quality. The powder coating manufacturer recommends a target film thickness range for coatings with good performance characteristics and these parameters meet customer expectations.

Powder Film Thickness Pre-cure and post-cure film thickness can be measured using several different instruments. See Figure 2 for example. Every powder coating operation should know what equipment is available and how to use it.

2. The necessity of measuring film thickness

Film thickness is arguably an important measurement during the application and inspection of protective coatings. Powder coatings are designed to perform their intended function when applied within the thickness range specified by the manufacturer. The physical and appearance properties of many finished coatings are directly affected by the dry film thickness (DFT). DFT affects the color, gloss, surface profile, adhesion, flexibility, impact resistance and hardness of the coating. If the film thickness is not within tolerance, the installation of the coated assembly will also be affected.

Accurate measurement of coating thickness has other benefits as well. Whether it can meet the requirements of the International Organization for Standardization (ISO), product quality or customer requirements for process control, companies need to confirm the quality of the coating to avoid wasting money on reworked products. By inspecting their application equipment, they ensure that the applied coating complies with the manufacturer's recommendations.

Applicators need to apply powder coatings evenly and according to product specification sheets. Applying too large a DFT is not only wasteful but also runs the possible risk of incomplete cure and can greatly reduce the overall performance of the coating system. High film builds generally result in low bond strengths. The coating is easily peeled or cracked from the substrate. Regular inspection reduces the amount of internal rework and customer returns due to processing defects.

3. Conform to the standard

Powder coating thickness is measured using different measurement methods depending on whether the test is performed before or after the powder has cured. The American Society for Testing and Materials (ASTM) has a series of standards describing these techniques.

Test Method D 4138 describes a destructive measurement method for testing solid substrates with a slicing instrument.

Practice D 7091 describes nondestructive measurement methods for metallic substrates using magnetic and eddy current Thickness Gauges.

Test Method D6132 describes the nondestructive measurement of nonmetallic substrates with an ultrasonic Thickness Gauge.

Standard D 7378 describes three methods of measuring the thickness of prepared precured powder coatings to estimate the cured thickness.

4. Overview of film thickness measurement

Film thickness measurements can be made before or after curing and crosslinking. The type of substrate, the thickness range of the coating, the size and shape of the coating, and the economics of the job determine the measurement method used.

On uncured powder coatings, height measurements can be made with powder combs and electronic gauges using dedicated powder probes. Since the thickness of the powder coating will decrease during curing, the reduction factor should be determined to predict the DFT after curing. In addition, ultrasonic instruments measure uncured powder without touching the surface and can automatically predict the cured thickness of the powder.

After curing, a variety of handheld devices allow direct DFT measurements on the coated part. These non-destructive thickness measuring instruments should choose magnetic induction, eddy current or ultrasonic principle according to the type of substrate. Less common methods include micrometer measurements, destructive dry film methods such as cross sectioning, and gravimetric (mass) measurements.

1. Standard unit of measurement

The normal standard unit used in American powder thickness measurements is the mil; 1.0 mil equals one thousandth of an inch (1/1000 of an inch). If the manufacturer specifies a thickness of 2.0 to 5.0 mils, the final cured thickness of the powder should be between 0.002 inches and 0.005 inches. The metric unit of measurement is called a micron (micron); 25.4 microns equals 1.0 mil.

The applicator needs to apply the powder coating evenly and according to the product specification sheet. This provides the maximum benefit for a particular powder specification. Most thickness inspection specifications apply to the cured thickness of the powder, so we are seeing the emergence of different thickness measurement techniques.

2. Cured film thickness measurement

The micrometer was one of the original instruments used to detect DFT and is still used today. It has the advantage of measuring any coating/substrate combination, but has the disadvantage of requiring simultaneous measurement of bare substrate thickness. Two measurements are required: one with coating and one without. The difference between the two readings, the height change, is the coating thickness.

Two destructive techniques are also available. One is to observe the clad portion in the cut-off section through a microscope and measure the film thickness. The other is to use a zoom microscope to view a geometric cut through the cured coating. This method is required when inexpensive, non-destructive methods cannot be used, or when non-destructive results need to be confirmed.

A common method of measuring the thickness of cured powders is to use an electronic DFT gauge. They are handheld, easy to operate, and relatively low cost. They choose between magnetic induction, eddy current or ultrasonic principles depending on the type of material.

当零件是由钢制成的可使用机械计。其采用长久磁铁和一个校准弹簧。该装置测量将磁铁从涂覆钢表面拉出所需的力。磁拉断计是坚固耐用,操作简单,价格低廉,携带方便,并且通常不需要任何校准调整。它们在一些只需几个读数的生产场合是比较合适且经济的替代方法。

由于具有简单性、多功能性、准确性和具有保持记录功能的原因,电子DFT测量仪器对于大型和小型粉末操作都是非常热门的选择。他们使用磁感应原理测量钢底材,使用电涡流原理测量其他金属底材。有时会集两种原理于一台仪器中。测试的结果直接显示在易于读取的液晶显示屏(LCD)上。多种探头可选择用于测量不规则形状或精准测量非常薄或非常厚的涂层系统。

非金属底材测量如涂覆的塑料或木材要求使用超声波脉冲技术。这为之前行业无法以合理价格进行非破坏性质量控制提供一个可能。这种测量技术的一个好处是在一个多层涂层系统测量所述各个层的可能性。

3、预固化膜厚度测量。

到目前为止讨论的测量方法已经使用在部分固化后的粉末厚度。它也可以,甚至在某些情况下更可取的,在制备后立即测量涂层以预测固化后的粉末涂层的厚度。

如果涂层被不正当地施涂后,校正已经干燥或化学固化需要昂贵的额外的劳动时间,可能会导致膜的污染,并可能引入粘合性和涂层系统的完整性的问题。制备过程中测量膜厚度可确定涂布器是否需要立即校正或调节。

4、干粉末的测量。

虽然大多数粉末涂料规格规定了固化的目标厚度,这可以在最终固化和交联之前确定施涂的粉末是否符合厚度规格。

有很好的理由需要一个准确的固化DFT预测值,尤其是在移动线。取决于烘箱的长度,被固化的部分数量,以及固化过程所需的时间和固化后手动测量DFT值的时间,在操作者为做一些必要的修改而在应用过程中进行干预之前有一个相当充分的延迟时间。

如果发现涂层缺陷,相当大的涂覆部分不得不在一个修配环中重新加工,或者如果重新加工的成本太高,它们甚至可能不得不废弃。对于某些操作,对于满足现代加工程序的要求这些缺点是无法接受的。

在预固化、预凝胶状态时测量粉末确保正确的固化膜厚度。这样能够在固化前对应用系统进行设置和微调。反过来,这将减少废料的数量和过度喷雾情况。准确的预测能够避免剥离和再涂层,不然可能会导致附着力和涂层完整性问题。

ASTM D 7378标准描述了测量涂覆粉末涂层的三个程序:

A.硬金属缺口(梳)计

B.带专用粉末探头的电子涂层测量仪器

C.非接触式超声波仪器

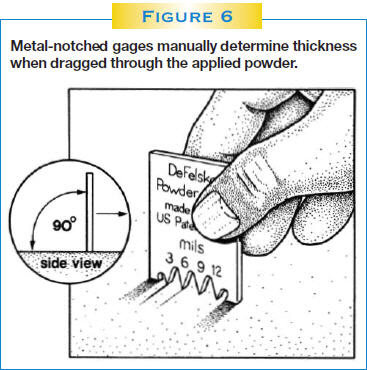

金属缺口计。这仪器通过手拖过涂覆的粉末手动地测量厚度。与湿膜测厚仪的工作原理类似,仪器确定的粉末高度值是在做有一个记号的、并且有粉末粘附在上面的最高编号的齿和没有留记号的、没有粉末粘附在上面的第二高的齿之间的高度。这些简单的工具便宜,但只能准确到几密尔。测量能够在一个合适的刚性底材进行,但记号将会在当粉末在固化过程中流动时没有被覆盖的粉末中标记。

电子测量仪。使用专用的粉末探头仪器能够测量涂覆的粉末厚度。内置在探头的微针穿透粉末涂层到底材上。然后将探头手动压在粉末层的表面实现厚度测量。这种方法仅适用于平坦的金属底材并且可能会在最终产品留下痕迹。

上述两种方法仅用于未固化的粉末涂层的高度测量。但如前所述,大部分厚度说明经常是指已固化的粉末厚度。由于粉末涂料通常在固化过程中在厚度减少高达50%,这两个步骤需要为每个特定的涂层粉末建立缩减因子来预测的固化膜厚度。减少因子的确定是通过在已经测量的未固化粉末高度的同一位置测量固化粉末涂层的厚度,然后测量前后两者相减获得。

非接触式超声波仪表。 ASTM D 7378的方法C描述了一种相对新型的仪器,这种仪器已迅速成为干粉厚度测量一个流行的解决方案。它是一个超声波仪器能够非破坏性在未固化的粉末上测量来预测最终的DFT值,并且不会留下任何影响成品的痕迹。

这些仪器是手持式和电池供电的,对于大多数粉末是开箱即可用。他们的操作简单和电子设计的特点使得其能够被线路操作者快速且有效地使用。

非接触是涂层厚度测量仪具有无损的决定性优势。这意味着,测量之后,测量的组件可以重新引入到正在进行的进程中。

五、膜厚度测量的精确度

这些仪器都是操作简单的,一个谨慎的用户应该定期验证他们的操作,尤其是当符合国际ISO标准规定程序。这三个步骤确保很好的的精度值。

1、校准

涂层测厚仪的校准通常是有设备制造商在受控环境中进行的一个文件化过程。校准证书显示可朔源到一个国家计量机构就可被发布。重新校准没有标准的时间间隔,也不是一个非常的要求,但可以在经验和工作环境的基础上建立一个标准的时间间隔。为期1年的校准间隔是许多仪器制造商提出了一个典型的频率。

2、验证

这是一个用户与已知的参考标准进行的精确检查。这个快速的检查能够确保仪器正常测量和用户正确操作它。对于许多测量仪,精度可以通过测量带有可追溯到国家计量机构的分配值的塑料垫片或环氧树脂涂层标准进行验证。

3、调整

调整,或校准调整,是校对测量仪的厚度读数以匹配已知的参考样品,为提高测量仪在其测量范围的特定部分内的一个特定的涂层的精确度的行为。此操作在粉末涂料工业很少需要的,因为在粉末涂层材料中的声学特性变化不大。

六、涂层质量控制

在当今竞争激烈的环境中,客户往往会选择具有坚实的质量控制系统的加工公司。通过在一个有记录和分析DFT结果的简单系统投资,粉末涂布者可以研究趋势,减少成本,并提供客户体现他们能够满足要求的参数的实力资料来留住客户。

一个质量保证(QA)程序是指开发一个简单的程序,要求在每一部分的相同位置进行一定数量的厚度测量。通过记录所有的数值,然后定期进行变化分析,并且采取必要的纠正措施。

通过笔和纸手动收集数据不仅耗时且容易出错,而且会对涂料项目增加显著成本。具有测量结果存储功能的测厚仪消除了这种风险。自动化采集读数的功能是保持成本在控制范围,减少人为错误的更好方法。在数字格式,数据可容易地存储,报告,和输出。

1、无纸化QA

电子数据的收集开始于具有以数字化形式收集测量数据的内存的电子测量仪。一些仪器甚至可以在测量过程中通过将作业或部分分离到批量存储器中产生基本的分析,并显示实时平均厚度结果和最小/最大极限。当一个厚度值超出规格范围就会产生报警,这样用户可以及时采取纠正措施。

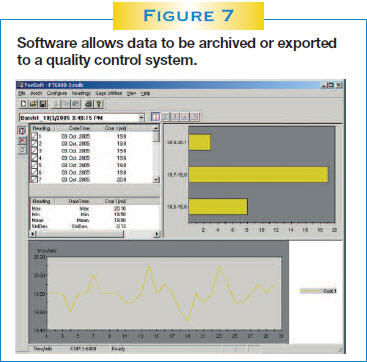

再者,需要将数据传送到一个软件程序。一些仪器能够通过无线输出每个测量的数据到过程控制器或个人计算机,比较常见的是在测量结束后或工作完成后经所有的测试结果存储到测厚仪的内存中并将其下载到PC。下载是通过与通用串行总线(USB)连接线或蓝牙无线通信来实现。这些数据的简单分析通常需要DFT测量仪器制造商的软件。该软件被安装在个人的个人计算机(PC),并直接与厚度测量仪进行通信。当厚度结果下载完毕后,该软件可以在公司的硬盘驱动器存档,输出信息到质量控制或统计过程控制(SPC)系统ISO或QS-9000记录系统,或选择格式打印数据。 (QS-9000是汽车行业发展的质量体系要求。)

2、基于网络的解决方案

粉末涂层应该意识到一个新兴的趋势——一个简单的,基于Web的模型。出产的测量仪器内置了闪存(大存储容量)且具有将测量数据无线上传到云归档和能够与世界上的任何基于Web的设备共享的功能。

USB海量存储,有效地替代了多种,如串行和并行端口接口。测量仪可使用USB海量存储设备类,它提供了一个简单的界面,在某种程度上类似于USB闪存驱动器,检索数据的相机,或数字音频播放器。当测量仪通过USB连接,任何计算机都可以通过虚拟驱动器的导航浏览和下载存储在测厚仪内存(批次)中的测量数据。使用通用的PC / Mac的Web浏览器或文件侦探器查看或复制存储的读数和图表。

第二个发展是云计算,对于任何涉及通过互联网提供服务的总称。对于粉末涂层操作,这意味着软件,数据,和处理器存储在受信任的服务提供者的服务器上。

3、云计算

云计算有许多优点,如以下内容:

1)上传的厚度读数可以被使用一个标准的互联网Web浏览器的世界上任何地方的网站或总公司所操控。

2)数据可以通过Web功能的设备访问,如个人电脑或苹果机,智能手机或平板电脑。

3)图像和教学笔记可以下载到涂层测厚仪提供计量指引。

4)测量数据可与授权用户通过任何计算机和大多数支持Web的设备安全登录共享。

5)硬件,软件和服务的成本降低。

6)数据备份和灾难恢复策略的改善。

7) Physical and IT security is managed by professionals.

8) They are efficient, flexible and scalable.

- 1Nondestructive measurement of dry coating thickness

- 2Coated steel coatings - Determination of dry-film thickness

- 3Application scheme of coating thickness test on wood board [with test video]

- 4Curved plastic coating thickness test application scheme [with test video]

- 5PosiTector200C ultrasonic coating Thickness Gauge on concrete coating thickness measurement application

- 6Coating Metering rodsFAQ

- 7Measuring method of nondestructive heat spray-on lining thickness

- 8Coulomb Thickness Gauge FAQ and Its Solutions

- 9What are the FAQs for paints Thickness Gauges? How to solve it?