Motorcycle film mass inspection?

1) Appearance of coating film

The appearance inspection of the paint layer includes: lack of paint (exposed bottom), blistering, cracks, peeling, rust marks, pitting, wrinkling, orange peel, pinholes, particles, dirt, scratches, sandpaper lines, poor coverage, coating Defects such as smoothness and flatness, poor decals, and parameters of distinctness of image and gloss.

The detection of the appearance of the coating film includes visual inspection and optical measurement. The visual method directly observes whether there are defects on the surface of the coating film; the optical measurement method uses various optical instruments to measure the gloss and vividness of the coating film respectively. The inspection of the appearance quality of motorcycle coatings is specified in detail in the standard QC/T29117.3.

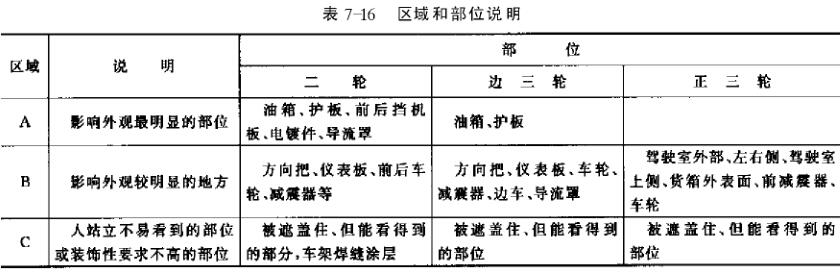

According to the degree of impact of each painted surface on the quality, the motorcycle surface is divided into three inspection areas, A, B, and C. See Table 7-16 for the description of the areas and parts.

① Gloss

Test according to the provisions of GB/T1743. Different motorcycle regions have different gloss requirements. Gloss can be measured by photoelectric gloss meter, multi-angle Spectrophotometer , etc. to detect more than 5 points, and take the average value.

② Visibility

It refers to the clarity of the image reflected by the coating film, expressed in DOI value (Distinctness of Image). It is mainly for further grade evaluation of the flatness of high gloss coating. The light source maps the image onto the surface of the coating, which is then reflected by the coating into the eyepiece, and the reflected image is observed by the human eye.

There are 13 rows of numbers in order of size on the digital board, and each row of numbers has a standard DoI value. At present, the national standard has no specific regulations on the DoI value of components in different regions, and the regulations of each motorcycle manufacturer are also different.

③Color

A common method is to compare with a standard color sample. When measuring the color, it should be compared under the light specified by the standard. For example, in the visual method, under natural scattered light or cIE standard light source, overlap the sample and the standard color plate by 1/4 area, and compare the eyes with the sample at 120°~140°. Some companies divide different grades according to whether there is any difference from the standard color plate and whether the difference is significant or not.

2) Thickness

The thickness of the coating film is very important and plays a decisive role in the protection of the substrate. The thickness of the wet film can be measured immediately after coating, or it can be measured after drying, and the measurement of dry film is more commonly used.

The dry film thickness can be measured with a magnetic Thickness Gauge on steel surfaces and with an eddy current Thickness Gauge on non-ferrous metal surfaces. The specific requirements are in accordance with GB/T1764 regulations, generally more than 5 points are detected, and the average value is taken.

3) Adhesion

The circle method is carried out according to GB/T1720-1989, and the cross-cut method is carried out according to GB/T9286-1988.

4) Hardness

Use pencil hardness or pendulum hardness as the standard.

5) Moisture and heat resistance

According to GB/T1740-1989.

6) Salt spray test (GB/T10125-1997)

Generally speaking, motorcycle coating requires 72h salt spray test without blistering or falling off.

- 1Working Principle and Application Analysis of Ceiling Salt Spray Tester

- 2Principle, significance and method of salt spray test

- 3Salt spray test NSS, ACSS, CASS difference

- 4Different test methods and similarities and differences of salt spray test

- 5Salt Spray Tester in salt spray testing

- 6Hardware salt spray test method

- 7Cyclic corrosion test and its test procedures

- 8How Salt Spray Tests Improve the Quality of Metal Plating and Coatings

- 9How does the surface coating prevent corrosion?