How to measure the Fineness of Coatings with a Scraper Fineness Meter?

1. Scope of application and description

The fineness is mainly used to determine the particle size and dispersion of pigments and system pigments in paints and mill bases, expressed in microns (μm). This method uses a scraper Fineness Meter to measure the fineness of the paint.

2. Using instruments and materials

(1) Minor paint knife or glass stirring rod

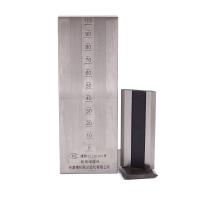

(2) Scraping rod fineness measurement ranges are 0-25μm, 0-50μm, 0-100μm, 0-150μm respectively. Specifications are single and double.

3. Measurement method

(1) Select scraper Fineness Meters with different ranges according to different types of coatings. Generally, if the fineness is below 30 μm and below 30 μm, it is recommended to use a scraper Fineness Meter with a range of 0-50 μm; if the fineness is 31-70 μm, use a 100 μm scraper Fineness Meter; 150μm scraper fineness gauge, and so on;

(1) Select scraper Fineness Meters with different ranges according to different types of coatings. Generally, if the fineness is below 30 μm and below 30 μm, it is recommended to use a scraper Fineness Meter with a range of 0-50 μm; if the fineness is 31-70 μm, use a 100 μm scraper Fineness Meter; 150μm scraper fineness gauge, and so on;

(2) The scraper fineness gauge needs to be cleaned with a solvent before use, and be careful to use a soft cloth when scrubbing.

(3) Use a small paint knife to fully stir the sample evenly, and then drop 2-3 drops of the sample into the deepest part of the groove of the scraper fineness gauge. It is recommended that the groove can be filled and slightly redundant.

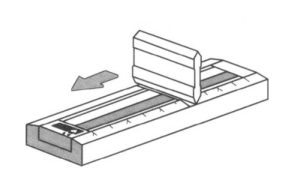

(4) Hold the scraper with both hands, place it horizontally on the top of the bottom plate of the scraper Fineness Meter, ensure that the scraper is in vertical contact with the surface of the bottom plate, and scrape it from top to bottom within 3 seconds at an even speed to ensure that the sample is filled with grooves and no residue is left on the plate. There is remaining paint.

(5) After the scraper is pulled, make the viewing angle and the groove plane form an angle of 15-30° within 5 seconds, observe the particles in the groove evenly through the light, and record the degree (accurate to the minimum graduation value). If individual particles are exposed on other graduation lines, there shall not be more than 3 particles within the range of reading and adjacent graduation lines.

4. Result representation

The paint fineness is represented by the groove depth (μm) of the scraper Fineness Meter at the point where the particles are evenly exposed, and the number of particles within the range of the fineness degree and the adjacent graduation line shall not exceed 3, and the parallel measurement is performed 3 times, and the results are taken twice as close to the reading. arithmetic mean.

Note: The error of two readings should not be greater than the minimum division value of the instrument.

Conversion of fineness

In addition to expressing the fineness in microns (μm), there are also Mill (mil), (1mil=25.4μm), Hegmann (Hegmann) registration (0-8 grades) and FSPT specifications (0-10 grades) to express . Their conversion relationship is shown in the figure:

5. Reference standard

National Standard GB/T 1724 "Determination of Coating Fineness"

6. Commonly used scraper Fineness Meter type suggestions

- 1Coating fineness of ground - Fineness gauge

- 2Coating fineness test method and influencing factors

- 3Fineness Detection of Precious Metal Slurry in Microelectronic Technology with Fineness Meter

- 4Inks Fineness gauge principle results and usage introduction

- 5Basic Principle and Application Analysis of Coating Fineness Scraper

- 6Coating Fineness Determination and Its Importance

- 7Detection Steps of Coating Fineness and Operation Method of Ground Gauge

- 8Coating fineness measurement and its role in Coating quality control

- 9Importance and role of coating bar in Coating and coating applications