Modern environment WDW-20 microcomputer controlled electronic universal testing machine operation instructions

1. Project introduction:

Domestic microcomputer-controlled electronic multifunctional testing machines started in the early 1990s. Our company is one of the enterprises that absorb foreign professional technology and develop electronic multifunctional testing machines. In order to improve the technical level of the company's products, the company has absorbed professional technology at home and abroad, so that the company's product technical level has leapt to a new level.

2. Fields of use:

The testing machine adopts stepping or AC servo motor as the power source; adopts professional chip integration technology, professionally designed PCI data acquisition amplification and control system, and realizes full digital adjustment of test force, deformation amplification, and A/D conversion process. This machine can test and analyze the mechanical properties of various metals, non-metals and composite materials, and is widely used in aerospace, petrochemical, machinery manufacturing, wires, cables, textiles, fibers, plastics, rubber, ceramics, food, medicine Packaging, aluminum-plastic pipes, plastic doors and windows, geotextiles, films, wood, paper, metal materials and manufacturing industries, can automatically calculate the maximum test force value, fracture force value, yield value according to GB, JIS, ASTM, DIN, ISO and other standards Tensile strength, upper and lower yield strength, tensile strength, compressive strength, elongation at break, tensile modulus of elasticity, flexural modulus of elasticity and other test data.

Three, according to the standard:

The configuration of relevant auxiliary equipment meets the national standards GB/T228-2002, GB/T228-2010 "Metal Materials Tensile Test Method at Room Temperature", GB/T7314-1987 "Metal Compression Test Method", GB/T232-2010 "Metal Bending Test Method" ", GB/T9341-2000 "Plastic Bending Properties Test Method", GB/T2568-1995 "Resin Casting Tensile Test Method", GB/T1040-92 "Plastic Tensile Properties Test Method", GB/T1041-1993 " Plastic Compression Performance Test Method",: GB/T 9341-2000 "Plastic Bending Performance Test Method", GB/T 25042-2010 "Glass Fiber Architectural Membrane", in line with the data of GB, ISO, ASTM, DIN and other standards deal with. It can be manufactured according to the user's requirements and standards provided.

GB/T16491 "Electronic Multifunctional Testing Machine";

GB/T2611 "General Technical Requirements for Testing Machines";

GB/T6825.1 "Inspection of Static Uniaxial Testing Machine Part 1: Inspection and Calibration of Force Measuring System of Tensile and (or) Compressive Testing Machine";

JB/T6146 "Extensometer Specifications";

JJG475 "Verification Regulations for Electronic Multifunctional Testing Machines"

4. Key description:

1. Host: The machine adopts a gantry floor-standing double-space structure, which can be pulled up and pressed down, and the beam can be raised and lowered to adjust the speed steplessly. The transmission system is composed of a low-noise arc synchronous tooth belt deceleration system and a ball screw pair, with stable operation, high efficiency, low noise and no pollution.

2 attachments:

Standard configuration: a pair of lever-type stretching attachments and compression attachments. The stretching attachment adopts a manual clamping method, which is convenient, reliable, and non-slip. During the clamping process, the jaws do not move, and the clamp body moves up and down. The sample is not subject to additional force, which ensures the accuracy of the test results.

5. Function Introduction

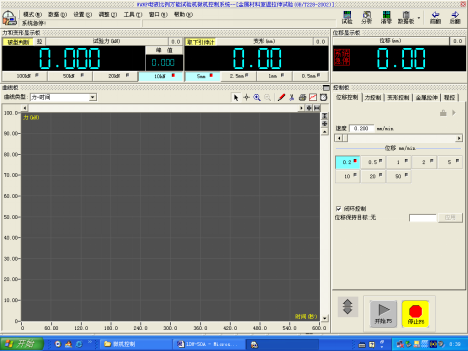

a) This machine adopts a built-in controller, which ensures that the testing machine can realize constant velocity displacement control.

b) Using stepping or AC servo motor, the performance is stable and reliable, with over-current, over-voltage, over-speed, overload and other protection devices. The speed ratio can reach 1:10000.

c) The electrical control circuit refers to the international standard, conforms to the national testing machine electrical standard, and has strong anti-interference ability, which ensures the stability of the controller and the accuracy of the experimental data.

d) Automatic shifting: automatically switch to the appropriate range according to the load to ensure the accuracy of the measurement data; realize the automatic shifting, zeroing, calibration and automatic shifting of physical zeroing, gain adjustment and test force measurement in the true sense Save to disk, without any analog adjustment link, the control circuit is highly integrated

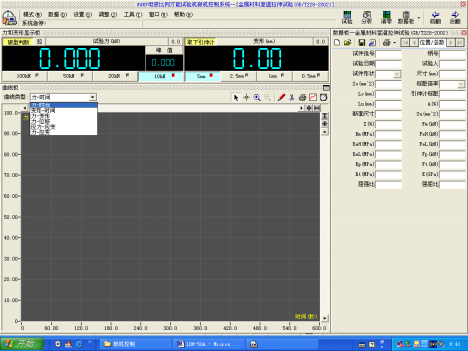

e) Condition storage: test control data and sample conditions can be made into modules, which facilitates batch tests;

f) Automatic speed change: during the test, the speed of the moving beam can be changed automatically according to the preset program or manually;

g) Automatic calibration: the system can automatically calibrate the accuracy of the indication;

h) Automatic saving: after the test is over, the test data and curves are automatically saved;

i) Process realization: the test process, measurement, display and analysis are all completed by the computer;

j) Batch test: For samples with the same parameters, it can be completed sequentially after one setting;

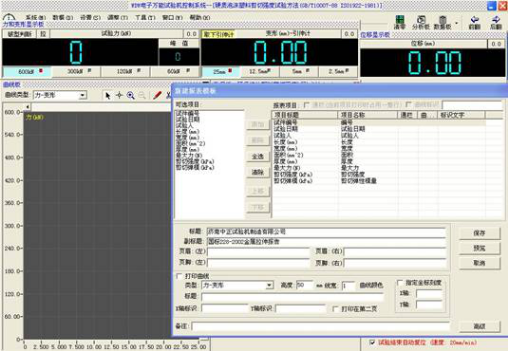

k) Test software: Chinese WINDOWS interface, menu prompts, mouse operation;

l) Display mode: data and curves are dynamically displayed along with the test process;

m) Curve traversal: after the test is completed, the curve can be re-analyzed, and the test data corresponding to any point on the curve can be found with the mouse;

n) Curve selection: Curves such as stress-strain, force-displacement, force-time, displacement-time can be selected for display and printing as required;

q) Test report: The report can be compiled and printed according to the format required by the user; it has a network interface, which can carry out data transmission, storage, printing records and network transmission printing, and can be connected to the internal LAN or Internet of the enterprise.

r) Limit protection: with program-controlled and mechanical two-level limit protection;

s) Automatic stop: After the sample breaks, the moving beam stops automatically;

t) Overload protection: when the load exceeds 3-5% of the maximum value of each gear, it will automatically stop;

Two modes of automatic and manual are used to obtain the test results, and the report form is automatically formed, which makes the data analysis process simple.

6. Main technical indicators

a) Maximum test force: 20kN;

b) The test force is not graded, the measurement range: 2%-100%;

c) Test force measurement accuracy: ±1%;

d) Displacement speed control range: 0.01~500mm/min, speed setting in stages;

e) Tensile test space: 0~700mm;

f) Compression test space: 0~700mm;

g) Test space width: 0-400mm;

h) Power supply power: 750W, 220V, 50Hz.

Seven, the main configuration

i) One host of 20kN gantry floor-standing high-strength testing machine (including dazzling golden aluminum alloy shell);

j) One set of high-strength clip-type tensile attachments (clamping width ≥ 75mm);

k) A set of high-strength compression accessories (Φ100mm);

l) Taiwan, CHINA TECO AC servo speed control motor and system;

m) Low noise arc synchronous gear belt reduction system;

n) Two pairs of Taiwan, CHINA ABBA precision ball screw (installed in the host);

o) One high-precision 20KN load sensor;

p) One high-precision 2000-line photoelectric encoder;

q) One Lenovo brand computer (2G memory, 500G hard disk, 18.5-inch LCD screen display);

r) One HP inkjet printer;

s) One set of full digital adjustment data acquisition board;

t) A set of WINDOWS compatible control software.

8. Quality Assurance

We are here to solve your problems at any time: you can call the service hotline from anywhere, professional engineers will provide you with solutions that meet your needs, and provide preventive maintenance, emergency repairs and system transformation. The product warranty period is two years and life-long service.