Introduction of the new ConductivityMeter

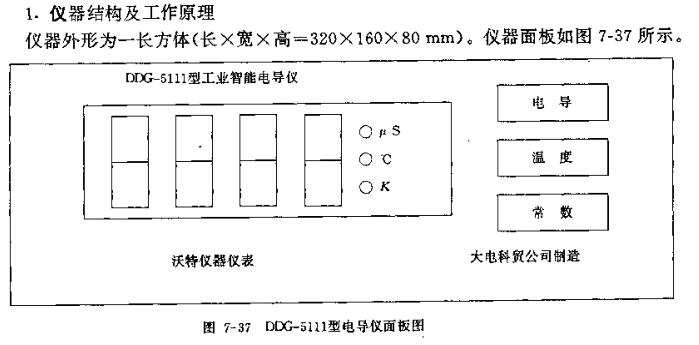

Introduce a new type of conductivity meter developed in the 1990s——DDG-5000 series industrial intelligent conductivity meter. The conductivity meter is composed of a conductivity transmitter and a conversion transmitter, which can continuously measure the conductivity of aqueous solutions in industrial processes. Widely used in power, power generation, chemical industry, beverage, food, brewing, environmental protection water treatment, pharmaceuticals, water plants and other departments.

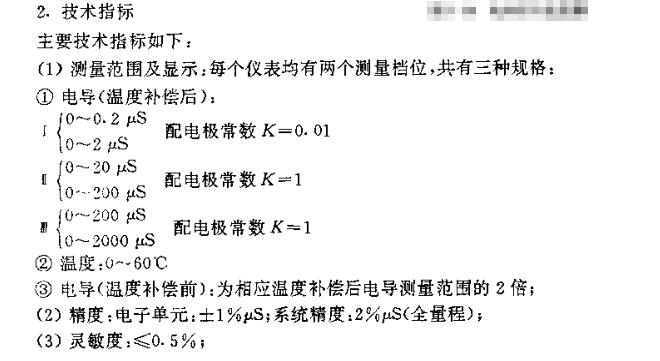

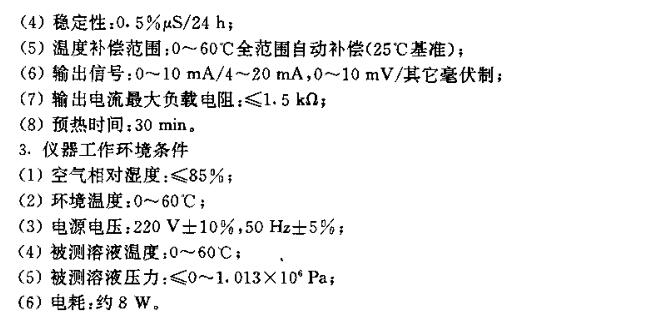

The outstanding advantages of this conductivity meter:

(1) The detection method is simple and reasonable, and fully utilizes the characteristics of the single-chip microcomputer. The detection signal is strong and the linearity is good. Once the problem of distributed capacitance of the conductance transmitter during long-line transmission is solved, manual compensation measures are not required, and the accuracy of the instrument is significantly improved.

(2) There is a digital oil wave program for parts rescue, which strengthens the anti-interference ability of the system.

(3) The temperature compensation range is wide, and the algorithm compensates for the full range of 0~60°C, but the influence of different temperatures and different concentrations on the temperature compensation coefficient is considered.

(4) Calibration and identification of software electrode constant: Due to the limitation of many factors, the conductance electrode constant deviates from the desired value. This table is equipped with software electrode constant correction and identification functions. All are operated by buttons, which is intuitive and convenient.

(5) A variety of display functions, the conductivity meter can display temperature, compensated conductance and temperature-compensated conductance. The display function of temperature and conductance without temperature compensation not only provides means for instrument calibration, but also provides conditions for online measurement comparison (without compensation and after compensation), which makes the operator more convenient.

(6) The film press structure has good anti-life, moisture-proof and good sealing performance, so it has strong adaptability to the environment.

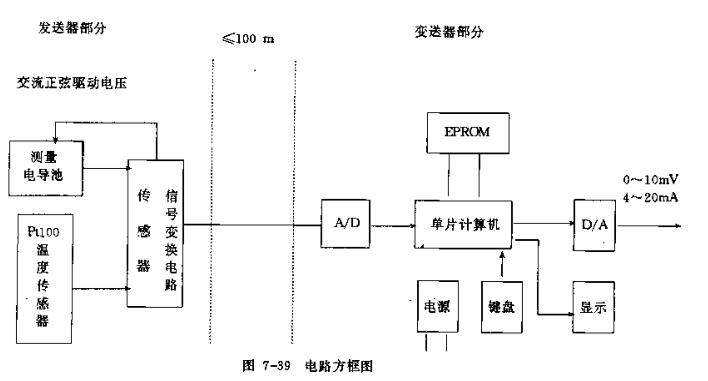

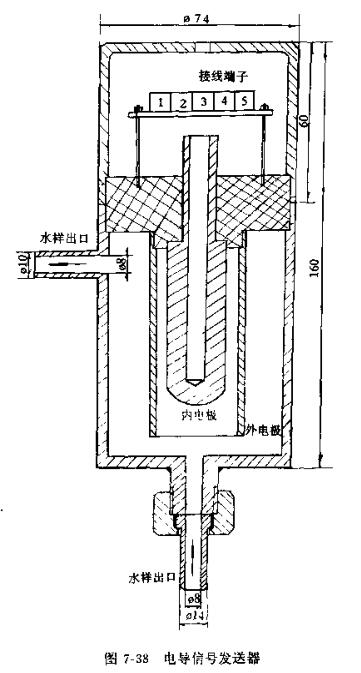

The conductivity signal transmitter (sensor) is a conductivity cell. Its working principle is a measurement conductivity cell with a fixed geometric size composed of a conductivity transmitter (sensor). The resistivity signal can then be converted to obtain the corresponding conductivity value. And because the conductance of a certain concentration of aqueous solution is a variable of temperature, it is necessary to perform temperature compensation in the measurement to make the conductance reflect the purity of the aqueous solution. The block diagram of the circuit is shown in Figure 7-39.

The reference AC driving voltage provided by the sine wave generator is applied to the measuring conductivity cell, and the detection signal taken out of the conductivity cell is processed by the sensor signal conversion circuit and transmitted to the transmitter by a long line, and the A/D system of Huiji converts the analog signal into Corresponding to the digital quantity, the single-chip computer software converts the conductivity value of the immediate solution. The temperature signal is given by another temperature sensor composed of P, 100, which is also entered into the single-chip microcomputer system by the above-mentioned processing. The software program integrates the influence of temperature and solution concentration on the temperature compensation coefficient, and performs temperature compensation correction on the conductance value (based on 25°C) ), then display and D/A output. Since the whole system is based on the single-chip microcomputer, a lot of work is done by the software, and the advantages of the intelligent computer's calculation table are fully utilized, so that the whole measurement is reasonable, simple and reliable.