Anmiao AL-150A-Probe C-CN Richter Hardness Instrument Operating Instructions

To use the instrument quickly, please follow the steps below:

1. Requirements for the workpiece to be tested

1. 1 When measuring, it is better to choose a solid and heavy measuring entity.

1.2 The surface finish of the tested material should not be less than 0.4 µm.

1.3 It is necessary to ensure that the measured material is firmly fixed to avoid bending, deformation, or movement during measurement, which will affect the measurement results.

2. Operation steps

2.1 Install the battery

Install the battery correctly according to the positive and negative labels on the battery box. 2.2 Turn on the machine and press the "POWER/MENU" key to turn on the machine.

2.3 Press the "DIR/SHIFT" key to set the impact direction after turning on the machine. 2.4 Select the code of the material to be tested, see section 4.3 for details.

2.5 Select the hardness standard for measurement, see section 4.4 for details.

2.6 Place the instrument on the surface of the material to be tested for measurement.

2. 7 loading.

2.8 Release and take a reading.

Precautions:

1. It is forbidden to hit the instrument with any tungsten steel or other materials with higher hardness, otherwise the instrument will be damaged.

2. When the instrument is not in contact with the material to be tested, do not press the release button under any circumstances, otherwise the support ring of the instrument will easily become loose, resulting in inaccurate measurement.

1. Product features and technical parameters

The basic principle of the Leeb Hardness Tester is that an impact impact speed and rebound speed of the impact body at a distance of 1mm from the sample surface. Using the electromagnetic principle, the induction and speed proportional to the voltage.

1.1 Applications

* Installed mechanical or permanent assembly components.

* Mold cavity.

* Heavy workpiece.

* Failure analysis of pressure vessels, turbogenerators and their equipment.

* Workpieces with very narrow test space.

* Bearings and other parts.

* Formal original records of test results are required.

* Material classification of metal material warehouse.

* Rapid inspection of multiple measuring parts of large workpieces.

1.2 Product Features

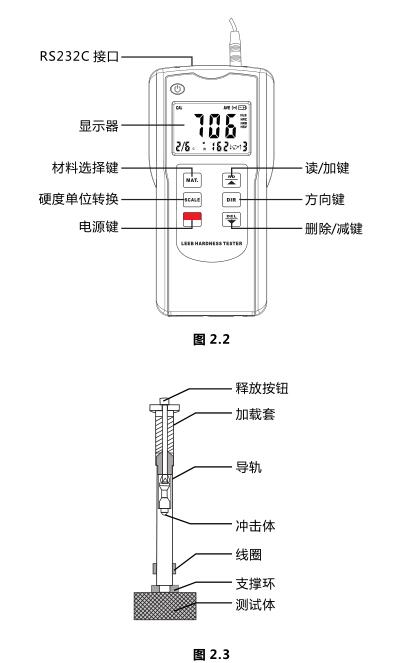

* The test material and test direction can be selected through the keyboard.

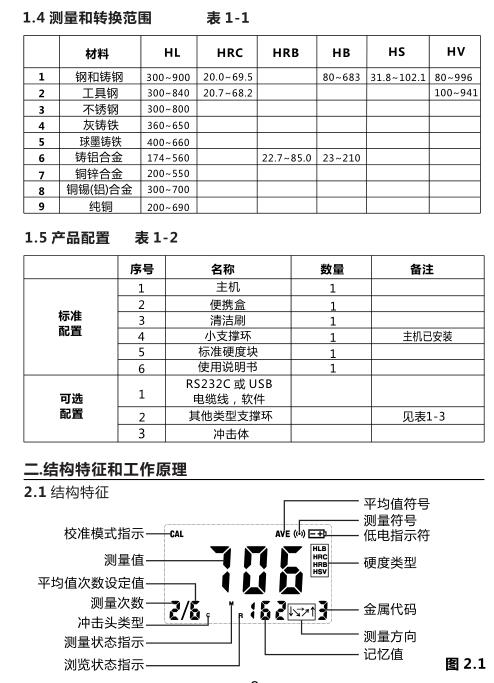

* It can realize mutual conversion between six kinds of hardness (HL, HRC, HRB, HB, HV, HS).

* The test results can be displayed repeatedly, and gross errors can be deleted.

* Can store 50 sets of measured values and test status, including material, test direction, hardness and other information.

* Allows user calibration to make measurements more accurate.

* With RS232 interface, it is convenient to communicate with the computer.

* With backlight display, it is convenient to use in a dark environment.

* Manual and automatic shutdown function.

* Low battery voltage indication.

1.3 Main technical parameters

Display: 12.5mm LCD with backlight.

Accuracy: relative error ±0.8% (HL=800), repeatability ±0.8%.

Measuring range: 200-900HL

Hardness conversion: HL-HRC-HRB-HB-HV-HSD

Measurable materials: 9 kinds

With RS-232 interface

Can store 50 sets of measured values and test status

Impact device: C type

Power supply: 4 1.5V AAA batteries

Size: 140×70×30mm

Weight: 130g (without battery)

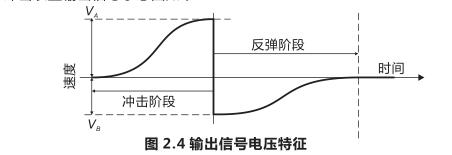

2.2 Working principle

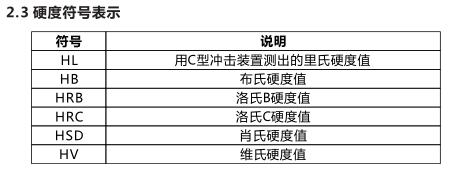

Its basic principle is that an impact body with a certain mass impacts the test surface , and measures the impact velocity and rebound velocity of the impact body at a distance of 1mm from the sample surface . proportional to the voltage. The Leeb hardness value is expressed by the ratio of the rebound velocity of the impact body to the impact velocity , and the harder material produces a greater rebound velocity than the softer one. Calculation formula: HL=1000×(VB/VA)

In the formula:

HL: Leeb hardness value

VB: Impact body rebound speed

VA: impact velocity of impact body

The schematic diagram of the output signal of the impact device is as follows:

The hardness value measured by the Leeb Hardness Tester is represented by HL, and the Leeb hardness value can be converted into other hardness units (including Rockwell B and Rockwell C, Vickers, Brinell and Shore D). When using the traditional static hardness test method to measure the hardness of the material, the change of the applied pressure will directly lead to the change of the hardness value. Similarly, in the Leeb hardness measurement, when you change the impact device, the hardness value will also change. Different impact devices are used to test the hardness of the same test block, and the Leeb hardness value will be different. That is: the hardness of a test block, the Leeb hardness value will also be different.

For example: 760 HLD≠760HLC≠760HLG

3. Measurement preparation

In order to ensure the measurement accuracy, in the process of making the surface of the sample, the influence of heat, cold working . The sample workpiece temperature needs to be lower than 120°C.

3.1 Weight requirements

The weight, thickness and solidity of the sample workpiece will directly affect the measurement of the hardness value. To obtain an accurate hardness value, workpiece selection is particularly important, and the surface hardness of the workpiece needs to be uniform.

* For heavy test pieces weighing more than 1.5kg, no support is required;

* For medium-sized samples with a weight of 0.5 to 1.5KG, it needs to be placed on a flat and solid plane, and the sample needs to be placed absolutely stably without any shaking;

* For light samples weighing less than 0.5KG, it needs to be tightly coupled with a solid support. The two coupling surfaces need to be flat and smooth, and the amount of coupling agent should not be too much. The test direction needs to be perpendicular to the coupling plane;

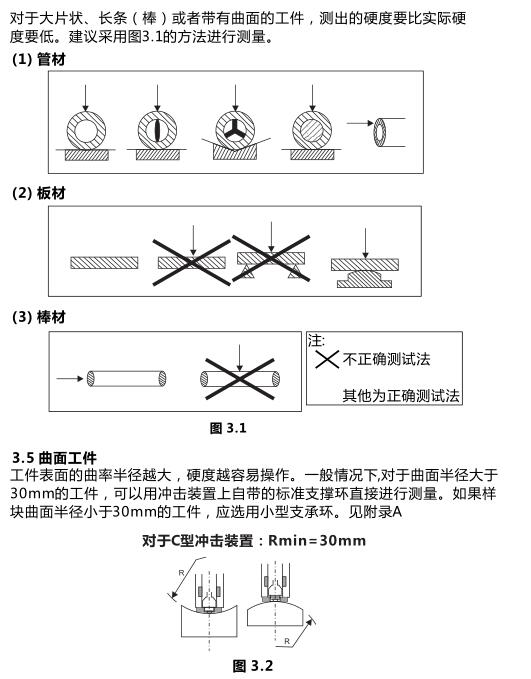

* When the test piece is a large-area plate, long rod, or curved piece, even if the weight and thickness are large, it may still cause deformation and instability of the test piece, resulting in inaccurate test values, so it should be reinforced or supported on the back of the test point.

3.2 Roughness requirements

The roughness of the sample surface will directly affect the measurement of the hardness value. In order to reduce this measurement error, the sample surface should be polished and have a metallic luster. The roughness value (Ra) needs to be ≤0.4um. Note: The rougher the surface of the sample, the smaller the hardness test value.

3.3 Cleaning requirements

In order to ensure the accuracy of the test, the surface of the workpiece to be tested needs to be clean and free from oil, dust and coatings.

3.4 Stability requirements

To avoid position shifting during measurement, the workpiece should be firmly fixed and the test surface should be perpendicular . Due to the impact of the impact body, the test area may be deformed or vibrated.

- 1Read the Leeb Hardness Tester in one article

- 2Leeb Hardness Tester different hardness system difference

- 3What products is the Leeb Hardness Tester with D probe suitable for measuring?

- 4Factors Affecting the Accuracy of Leeb Hardness Tester Testing

- 5Leeb Hardness Tester measurement requirements

- 6Factors Affecting the Test Accuracy of Leeb Hardness Tester

- 7What are the measurement requirements for a Leeb Hardness Tester?

- 8What factors affect the test accuracy, error and repeatability of the Leeb Hardness Tester?

- 9What is hardness testing? What types are there?

-

-

PRLH150 Leeb Hardness Tester$ 259.00

-

-

-

-