Introduction of ordinary electric Drying Oven

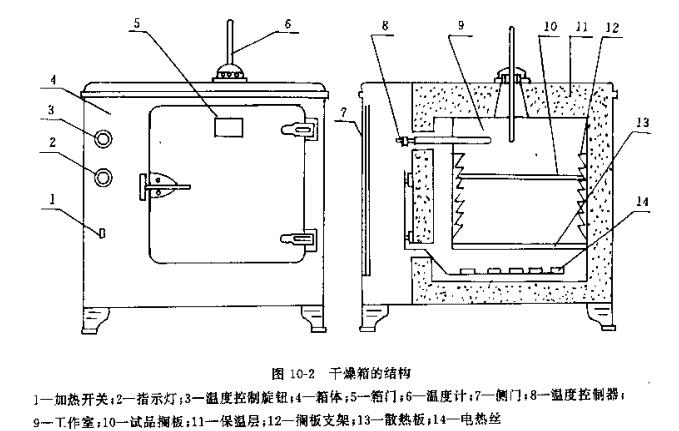

1. The structure of the drying box

As shown in Figure l0-2, the box is made of thin steel plates, and inside the box is a working room for placing items to be dried, and there are shelves in the room. There is an insulation layer filled with glass fiber between the working room and the outer shell. There is a glass door between the studio and the door for observing indoor items.

There is an exhaust valve on the top of the box to adjust the air in the room. A mercury thermometer is drawn in the center of the top of the box to indicate the temperature inside the box, and the temperature in the working room is automatically adjusted by a thermal expansion temperature regulator (usually a bimetallic temperature sensing element), and the temperature fluctuation range is ±1°C. Regulators, indicator lights, switches and other electrical equipment are installed in the side wall of the hand box, and the side door can be removed for hand inspection and repair of the circuit.

The heating wires in the electric heater are installed in subgroups under the working room, and are controlled by switch operation and temperature regulator respectively. Use the indicator light to indicate the working status of the electric heater.

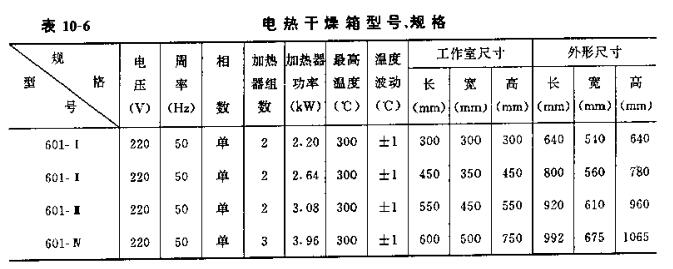

2. Specifications and models

Taking the products of Dalian Fourth Instrument Factory as an example, its specifications and models are listed in Table 10-6.

Shanghai Experimental Instrument Factory has similar products, with several specifications such as 202-1 as the first number.

3. Use and Precautions

The use method and precautions of 601 series electric Drying Oven are as follows:

(1) How to use

①Before use, it is necessary to check whether the power supply (voltage, current) meets the regulations and whether the ground wire is properly connected.

②The trial crystals can be put in only when all the parts are ready, and then come to the door. Put a thermometer in the hole of the exhaust room on the top of the box, open the exhaust door, and then connect the power supply to start working.

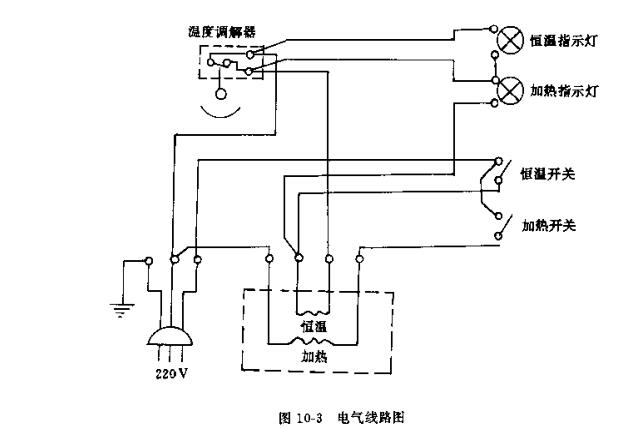

③ After connecting to the power supply, you can turn on the heating switch and regulator switch of the electric cooker, and turn the regulator knob from 0 to 10. At this time, the temperature in the box starts to rise, and the red light is over. When the temperature rises to the required working temperature, turn off the heater switch, turn the regulator to 0 position, when the indicator light of the rotary chamber changes from red to white, the temperature regulating electric heater will be powered off, the working temperature will drop, and then turn it to red Light, where the white and red alternates is the constant temperature point, and then fine-tune the knob until the indicator light turns to itself to make it constant temperature. It may be that the temperature continues to rise when the temperature is constant. This is due to the influence of overcooking, and it takes about half an hour to stabilize. Read the highest or lowest degree from the thermometer, and then adjust it until it is accurate. If you choose a lower working temperature, you can only use the temperature to adjust the electric cooker to save power.

④ After constant temperature, it can work normally. During use, it can be automatically adjusted by the temperature regulator inside the box, which can maintain a constant temperature for a long time without manual management.

⑤ If you want to observe the condition of the test product in the studio, you can open the door and observe from the glass door. However, the door of the box should not be opened normally so as not to affect the constant temperature or the glass door will be broken due to rapid cooling.

Its electrical circuit is shown in Figure 10-3.

(2) Precautions for use

① The object to be dried should not be placed on the cooling plate, because it is close to the electric cooked wire, and the temperature is far higher than the temperature controlled by the dry operation box.

②The box should be placed in a dry and horizontal place indoors. It does not need to be fixed on the surface. It should have a reliable grounding wire.

③Volatile, corrosive and explosive items are not allowed to be placed in the working room.

④ When not in use, the power should be cut off, and the regulator knob should be turned back to the original position 0 to ensure safety.

⑤ Do not remove the side door arbitrarily, adjust or change the line at will. When a fault occurs, the side door can be removed and checked one by one according to the line to eliminate the fault.

- 1How to calibrate Vacuum oven?

- 2Principle, application and selection of vertical Electric Forced Air Drying Oven

- 3Principle, application and selection of pigment Drying Oven

- 4Principle, application and selection of electric heating air Drying Oven

- 5Principle, application and selection of vacuum electric Drying Oven

- 6Principle, application and selection of nitro paint Drying Oven

- 7Principle, application and selection of industrial hot air circulation Drying Oven

- 8Principle, application and selection of small Drying Oven

- 9Principle and Application of Electrothermal Vacuum oven