Introduction to the operation and application of vacuum Drying Oven

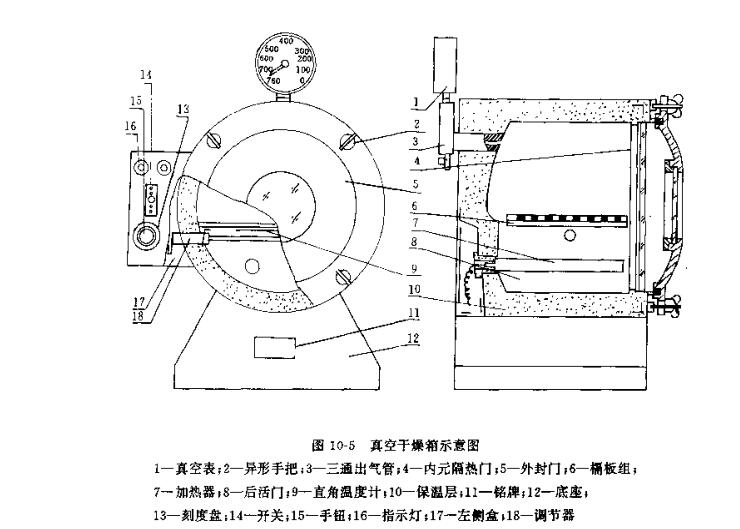

In the chemical laboratory, it is necessary to dry some organic compounds and other substances. In order to avoid pyrolysis during the drying process, vacuum drying is used. The commonly used equipment is a vacuum Drying Oven. The box of the vacuum Drying Oven is generally a horizontal cylinder with a base underneath. As shown in Figure 10-5, the front end of the finger body is a double-layer sealed door with glass windows; the sealing gasket of the inner and outer doors is made of anti-cooking glue. The real temperature in the room can be observed through the window. There is a vacuum gauge and a valve at the back end of the finger body, and the door is closed to the vacuum. Second, the electric heating air drying box. As shown in Figure 10-4. Its worry point is that it can quickly dry the baked objects in the finger.

The product model of Liaoyang Constant Temperature Instrument Factory is LH101, the model of this kind of product of Tianjin Experimental Equipment Factory is marked as "HC one mouth", the model of Nanjing Experimental Instrument Factory is marked as "HG101 one mouth", and the model and specification of Dalian Fourth Instrument Factory are shown in the table 10-7.

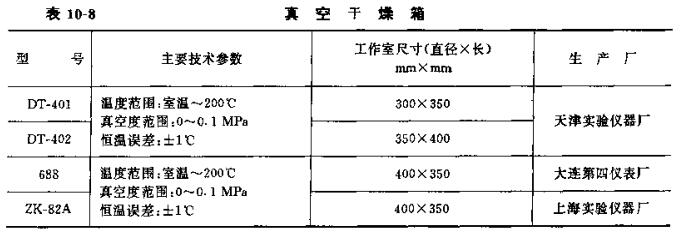

Vacuum line hose connection. The temperature control system is the same as other electric cooked dryers. Table 10-8 lists the specifications of several domestic vacuum drying fingers.

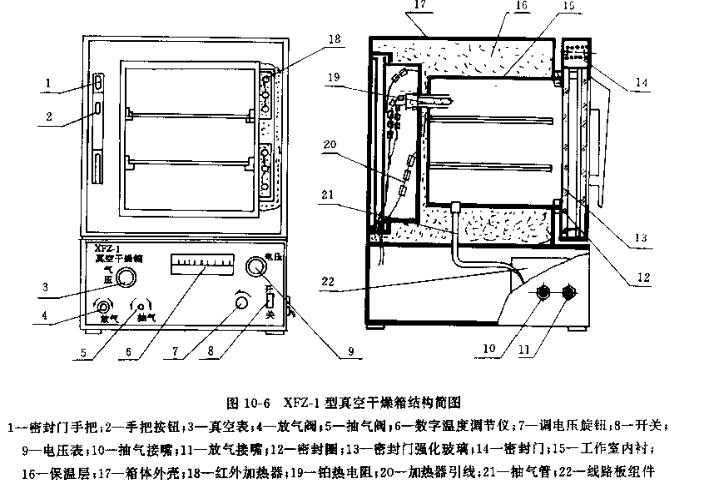

The following introduces a relatively advanced XFZ-1 vacuum drying finger (product of Dalian Fourth Instrument Factory in the 1980s).

1. Structure and features (see Figure 10-6)

(l) The studio is square, made of stainless steel plate (1Cr18Ni9Ti) or low-carbon steel plate cold pressed, with a two-story scaffolding inside. Improve space utilization and service life.

(2) The airtight door is sealed with a magnetic rubber ring with good heat resistance, which is light and flexible to open and close; the observation window on it has two layers of glass inside and outside, and the inner layer is 12mm reinforced glass. Safe and reliable, good thermal insulation performance, uniform temperature field, easy to observe.

(3) Square infrared heaters (four pieces) are placed on both sides of the sub-studio.

(4) The temperature in the working room is measured with clamp resistance (Pt100) and directly displayed with XMT-32 digital temperature regulator. It has the advantages of convenient observation, clear reading without parallax, high precision and good vibration resistance. It can adjust and automatically control according to the set temperature.

The voltage of the heating power supply is regulated by the thyristor voltage regulation method, and the controllable conduction angle is adjusted through the phase-shift trigger circuit to achieve the purpose of yuan-level production regulation. A better constant temperature accuracy can be obtained.

(5) The vacuum gauge is placed on the left side of the board, and there is an air extraction valve on the lower side, which is convenient for switching between air release and adjustment.

2. Technical indicators

(1) Power supply: ~220V, 50Hz;

(2) Heating power: 1.6kW;

(3) Temperature rise range: room temperature ~ 200°C;

(4)真空度范围:0~0.1MPa(2.5级表);

(5)恒温误差:≤士1℃;

(6)升温时间:«80min(200℃);

(7)真空密封性:真空度»0.043MRa(由0.0997Wa起,经过24h);

(8)工作室尺寸:300>(300>(350mm(31.5L)

(9)棚架荷重:15kg(分散分布)。

3.燥作方法

(1)使用前要清理干净箱内杂物灰生。

(2)用機皮管将箱左侧的抽气口与真空泵的抽气口连接起来,关闭箱门。开泵试抽,以检査抽气東、调、真空表、接头是否漏气。

(3)接通电源,扳动板面右下角的开关,数字表通电。把数字表右下处“开关”扳至设定位置上,旋动设定器扳,将要控制(设定)的温度在数字表上准确地显示出来。再将开关扳回至实值位置上,至此检查准各完成。

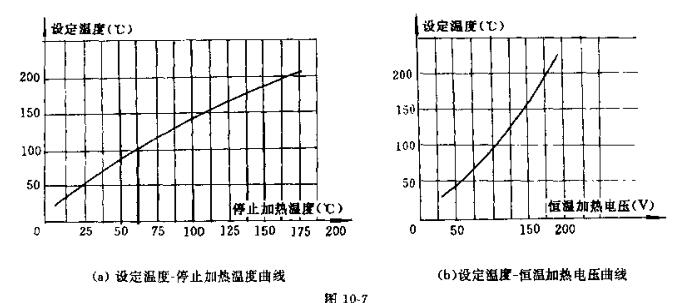

(4)升温:先把要实验的材料装入箱内,关闭箱门,再开动真空聚,抽真空并开始满功率加热升温(将电压调节旋組向右旋至最大)。见图10-7,当数字仪表显示出由图10_7(a)(设定温度一停止加热温度曲线)查出与设定温度相对应的停止加热温度值时,将电压调节旋組调至零,待仪表显示的温度接近设定温度值时,According to图l0-7(b)(设定温度一恒温加熟电压曲线)查出所需恒温加热电压值,将电压表指针调到该值后,可由仪表进行白动控制温度。

当温度超过设定温度时,数字仪表上的红色指示灯亮,加热器断电;当温度降到设定温度少许(1℃)加热器又通电加温,此时,数字仪表上的绿色、红色指示·灯交替内亮(在比例调节带内),周而复始,从而达到自动控制温度的目的。

(5)应用举例:以设定温度为100℃为例,先由图10-7(a)查出停止加热的温度为62C,满功率升温至数字仪表显示出62℃时,将电压调节旋組调至零。待仪表显示的温度接近设定点温度値时,如温度送到95℃时,按图10-7(b)查出所需1宣温加热电压值为100V,将电压表指针调到该值上即可由仪表进行自动控相温度。

The above two curves are tested under the condition that there is no material in the box. When using, according to the amount of materials in the box and the difference in ambient temperature, when selecting the stop heating temperature and the constant temperature heating voltage, appropriate adjustments should be made to increase or decrease.

(6) After the work is finished, cut off the power immediately to ensure safety.

(7) After the work is finished, the air release valve can be opened to let the air flow slowly enter the working room; the airtight door should also be opened slowly to avoid the intrusion of the cold air and the impact on its service life.

4. Safety maintenance

(1) The drying box should be placed in a stable place.

(2) Regularly check whether the circuit connection parts are solid, especially the electric heater circuit should not be loose.

(3) Since there is no explosion-proof device, volatile explosives are not allowed in the studio.

(4) Check the vacuum gauge and Vacuum Pump regularly.

(5) The outside of the box needs to be grounded.

(6) Do not dismantle the sealing rubber ring and bumper mechanism of the door at any time.

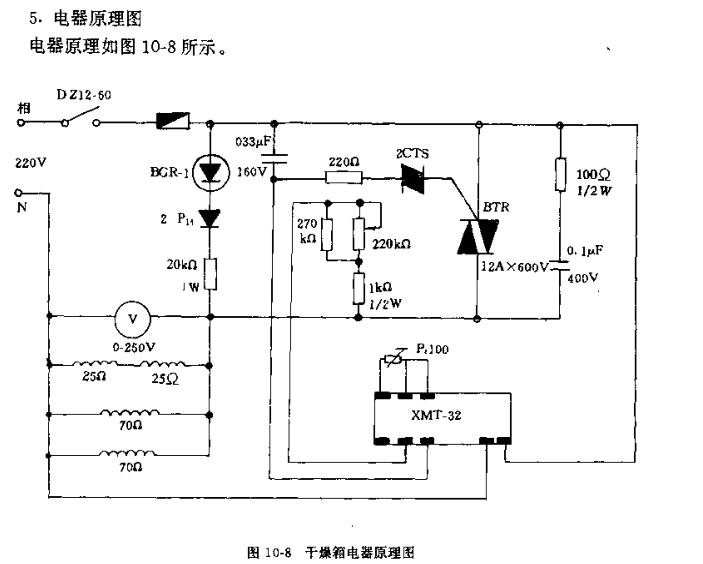

5. Electrical schematic diagram

The electrical principle is shown in Figure 10-8.

At present, there is a new type of Drying Oven (ZL series products) that is being gradually adopted. Its structure is that the working chamber is made of anti-corrosion materials, and there are electric heating films on its outer wall. Stamping forming, with temperature automatic control device.

Compared with ordinary Drying Ovens with the same function, its advantages are small size, light weight, power saving, and long life. Because the working room is not connected to the heating element, it has anti-corrosion and explosion-proof functions. In addition, because the heating film is evenly distributed outside the working room, it can The temperature is uniform and the temperature rises quickly.

- 1How to calibrate Vacuum oven?

- 2Principle, application and selection of vertical Electric Forced Air Drying Oven

- 3Principle, application and selection of pigment Drying Oven

- 4Principle, application and selection of electric heating air Drying Oven

- 5Principle, application and selection of vacuum electric Drying Oven

- 6Principle, application and selection of nitro paint Drying Oven

- 7Principle, application and selection of industrial hot air circulation Drying Oven

- 8Principle, application and selection of small Drying Oven

- 9Principle and Application of Electrothermal Vacuum oven