Testing of horizontal fluidity of coating powder

(1) Definition

Horizontal fluidity is the diameter of a test piece that is compressed into a specified size and melted at a certain temperature, and the unit is expressed in mm.

(2) Equipment

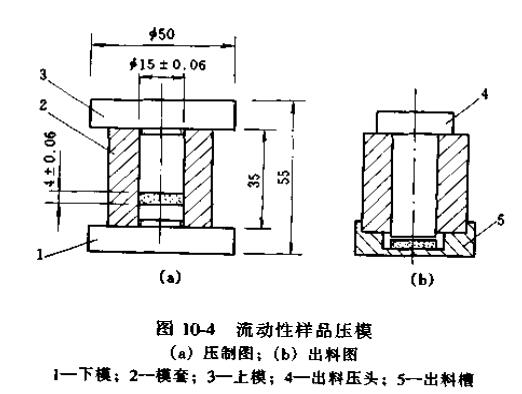

Fluid sample compression molding, see Figure 10-4.

Hot plate: the same Hot Plate used to measure gelation time.

Stopwatch or other timers: accurate to o.2s.

Mercury thermometer: can measure 0~250℃.

Balance: Sensitivity 0.1g.

Dividers and rulers

(3) Test procedure

Weigh 0.8-1g powder sample (depending on the amount of inorganic pigment in the powder, 0.8g can be taken when there is no domain material at all), put the mold cover on the lower mold, pour the powder sample carefully and level it, and put it on the upper mold , Press the whole set of molds with a vise or a press until there is no gap between the upper and lower molds and the mold sleeve. Take out the upper and lower molds, and take out the test piece in the mold sleeve with the ejector pin and the shield. If the test piece has obvious side thorns, it should be carefully cut off with a blade.

Heat the Hot Plate and keep it at the required temperature, coat the surface with a thin layer of release agent, place the test piece on the Hot Plate and time it. When the test piece melts and cannot continue to flow, or after the specified time, use a divider to measure carefully Find the diameter of the test piece, then measure the size with a steel ruler, and use two test pieces for the test.

(4) Results

Take the average of the two test values as the horizontal fluidity of the tested material, in mm, accurate to 0.1mm.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method