Detection of inclination fluidity of coating powder

(1) Definition

The oblique fluidity is the distance that the powder is compressed into a test piece of a specified size, and when it is placed at a 65° inclination angle under a certain temperature condition, it will flow when it is melted to the melting point.

(2) Equipment

The temperature of the constant temperature oven is -200°C, and the sensitivity is ±1°C.

Metal plate assembly frame: 50mmx120mm metal frame, installed in the oven, use the external joystick of the oven to keep it in a horizontal position, or at an angle of 65°.

Tin plate: 50mmx12(1mmx(0.2-0.3)mm.

Analytical balance: Sensitivity 0.lmg.

Stopwatch: Scale 0.ls.

Steel ruler: the scale is 0.5mm.

Steel sample compression molder: capable of preparing powder test pieces with a thickness of 6mm and a diameter of 12.7mm (refer to Figure 104 for processing)

(3) Test procedure

① Weigh 0.5~0.7g of powder coating and put it into a steel press, and press it into a test piece with a thickness of 6M.

① Weigh 0.5~0.7g of powder coating and put it into a steel press, and press it into a test piece with a thickness of 6M.

②Put the test piece on the 12.7m-diameter refractory place, and put it on the metal rack in the oven that has been kept at a constant temperature (generally, the curing temperature or the specified temperature), and quickly close the oven door. Keep the metal rack in a horizontal position for 3 min.

③Manipulate the metal frame, tilt it at an angle of 65° from the horizontal position, and keep it at this inertial angle for 30 minutes.

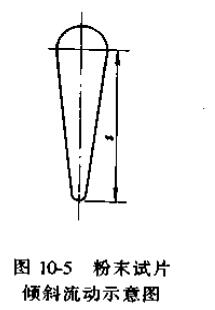

④ Take out the sample plate from the oven, cool it to room temperature and draw a marking line with the maximum flow distance, measure the distance from the center line of the test piece on the original tinplate to the marking line (see s in Figure 10-5), expressed in mm.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method