Introduction of coating porosity (GB6554-86) detection method

This method is used to measure the number of pinholes and defects in the coating on the test specimen.

(1) Equipment

① DC high voltage generator The generator can generate DC output voltage, and it can be adjusted to ±5% and -10%. Its internal resistance should make the average value of the steady-state short-circuit current 3mA±0.3mA, and the maximum current during high-voltage flashover Between 10~50mA, the pulse charge should not exceed 25x10 -3 mC. One of the two electrodes of the generator is connected to the casing or protective conductor, and the other is connected to the high-voltage test head through a shielded high-voltage cable. The generator shall be equipped with a light or sound device to indicate each spark discharge on the test electrode.

②High-voltage test head: The test head is equipped with a protective resistor to limit the high-voltage flashover current (l0~50mA), and has a conductive sheath connected to the protective conductor outside.

③ Electrode: The electrode is made of soft metal brush or conductive rubber. The brush should be able to cling to the surface of the sample during the test and there should be no flow during the moving process.

(2) Sample

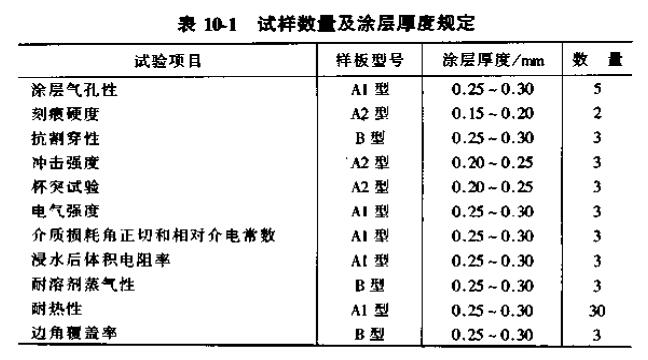

See Table 10-1.

(3) Test procedure

Adjust the test voltage at 15kV/mm according to the thickness of the coating. Move the electrode close to the surface of the sample at a maximum speed of 4 cm/s. The test voltage should be monitored during the test, allowing it to drop but not exceeding 10%. Coating pinholes or defects can be indicated by visible sparks on electrodes and optical or acoustic signals on equipment.

(4) Results

Report the number of pinholes or defects on each specimen.

- 1The reason for the coating defects caused by the aging of the paint film turned out to be...

- 2Why are there pores on the surface of the powder coating?

- 3Coat pinholing/coating sagging should be handled like this!

- 4Effect of solvent volatilization rate on coating appearance

郭晓娟;刘宁;梁笑丛;刘瀛 - 《信息记录材料》

- 5Analysis of coating defects caused by oil pollution on metal surface

- 6Cause analysis and control measures of anti-corrosion coating blister defects

樊志勇;吕建伟;杨媚媚 - 《全面腐蚀控制》

- 7Formation and identification of coating pinholings

吴贤官;沈志聪 - 《上海涂料》

- 8What are the causes of defects in coating construction?

- 9Film defect analysis and solution summary