Air Compressor type and working principle

An Air Compressor (also known as an air pump) is the most basic and important component of a compressed air supply system.

According to the different ways of compressing gas, Air Compressors are divided into two categories: volume type and speed type. The positive displacement Air Compressor changes the working volume through the reciprocating piston or the rotating rotor in the cylinder, so that the gas is compressed and the gas pressure is increased. The speed-type Air Compressor relies on the action of the high-speed rotating impeller to make the gas get a high speed, and then slows down sharply in the diffuser to convert the kinetic energy of the gas into pressure energy. The Air Compressors used in the spraying process are mostly volumetric. The type and structure diagram of the Air Compressor is shown in Figure 3-25.

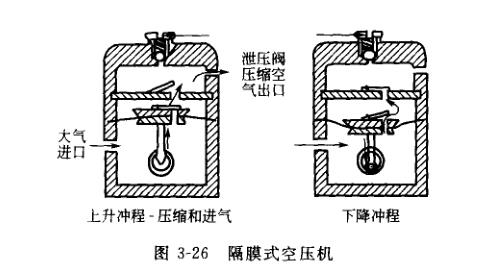

1. Diaphragm Air Compressor (oil-free type)

As shown in Figure 3-26, it is a portable Air Compressor. Due to its light weight, convenient movement and low cost, it is suitable for small-scale spraying at home. The body of the compressor is a die-casting part. There is a flexible diaphragm made of metal or synthetic rubber in the cylinder. Driven by the piston rod driven by the small electric motor, it reciprocates up and down in the cylinder. Send the incoming air into the compression chamber above the flexible diaphragm and close the compression chamber. During the upward stroke, the air in the compression chamber is compressed to a certain extent and then discharged. At the same time, the external air enters the cylinder, and the pressure range that can be generated is 206.8~ 241·8kPa compressed air. Since the machinery does not use lubricating oil, the compressed air does not contain oil, but contains moisture.

It should be noted during use that it can only be used for a short time and the wearing parts such as diaphragms and valves should be replaced in time according to work needs. This kind of pump generally needs to run continuously when it is started (some can also be designed as an automatic open/close type), and it cannot be started under load. Before starting, the air in the compressor must be emptied, and the excess compressed air can be used Discharge through the pressure relief valve on top of the compressor.

2. Rotary Air Compressor

It uses the rotating rotor or screw to change the volume of the intake air during the movement to achieve the purpose of compression. Among them, the rolling rotor type uses the slide plate to press the eccentric wheel under the action of the spring and rotates with the eccentric wheel, so that the volume of the crescent-shaped space separated by the slide plate is continuously expanded and reduced, so as to realize suction, compression, functions such as exhaust.

This kind of compressor has the advantages of compact structure, small size, light weight, less moving parts, less wearing parts, high operation reliability, small vibration, stable operation, low noise, easy installation and low price. Since lubricating oil is used for cooling and sealing during use, an isolator is installed on the machine to prevent lubricating oil from entering the air circuit system, but it still cannot guarantee that the compressed air does not contain oil, so an absorption filter should be installed behind the compressor outlet Further degreasing.

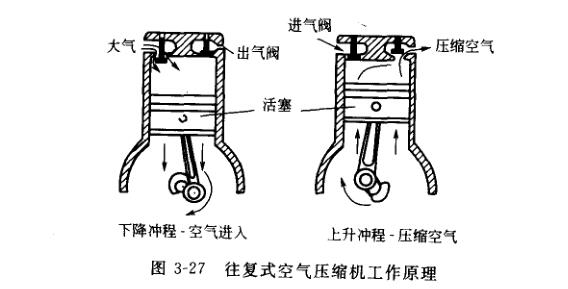

3. Reciprocating Air Compressor

The reciprocating Air Compressor is a type of compressor commonly used in the spraying process, and its working principle is shown in Figure 3-27. Its main components include pistons with piston rings, cylinders and intake and exhaust valves. The piston can be pressurized at one end or at both ends, which are called single-acting and double-acting respectively. It uses the piston to reciprocate in the cylinder to complete the steps of expansion, suction, compression and exhaust. Figure 3-27 is a working diagram of a two-stroke reciprocating Air Compressor. During the downstroke, the outlet valve is closed, and the intake valve is opened to complete the two steps of intake and expansion. During the upstroke, the intake valve is closed to complete the compression step. When the compressed air pressure reaches a certain level, open the outlet valve to complete the exhaust step. It is a mature production technology, but its disadvantages are complex structure, many wearing parts, and the pressure will pulsate because it cannot transmit gas continuously. Since lubricating oil needs to be added to lubricate the piston to reduce friction, take away heat, and strengthen the seal between the piston and the cylinder, there is oil in the compressed air, which requires degreasing treatment.

The process of inhaling air and compressing it to a certain pressure with one stroke cycle of the compressor is called a single-stage compressor. The compressed air pressure produced by a single-stage compressor can reach 68g.5kPa. When the pressure exceeds 689.5kPa, the efficiency of the single-stage compressor is quite low. In order to obtain a higher pressure, two-stage compression can be used, that is, two reciprocating compression cylinders are used for two compressions. In the low-pressure cylinder, the inhaled air is first compressed to a medium pressure of about 275.8kpa, and then cooled by a cooler. Then enter the high-pressure cylinder for further compression. The difference between the two cylinders is that the cylinder bores are different, and the diameter of the high-pressure cylinder is only about half that of the low-pressure cylinder. When it is necessary to obtain compressed air with a pressure in the range of 689.5~1379kPa, a two-stage compressor can be used. This range of pressure can meet the needs of most spray applications. If higher pressure compressed air is required, multi-stage compressors can be used. The multi-stage compressor can produce compressed air higher than 1379kPa, and the highest pressure can reach 82746kPa.

- 1Basic Principle and Application of Permanent Magnet Air Compressor

- 2Five steps to choosing the right Air Compressor

- 3What kind of Air Compressor do you generally choose for air Spray Gun spraying?

- 4Air Compressor selection of Fusheng

- 5Air Compressor application industry one table

- 6Iwata Air Compressor model selection method

- 7Iwata Air Compressor series standard configuration characteristics diagram

- 8Iwata teaches you how to use Air Compressor comfortably and efficiently?

- 9Common faults and treatment methods of compressors