Positector200 Ultrasonic Thickness Gauge measurement of coated Film thickness on concrete and masonry substrates

The Defelsko Positector 200 Ultrasonic Thickness Gauge is designed for the non-destructive measurement of the dry film thickness of coatings on concrete and masonry. This article comes from Defelsko and was professionally translated by NBCHAO. If you need to reprint the translation, please indicate.

application

Masonry substrates include stone, brick, tile, cast-in-place concrete, precast concrete, concrete block, asbestos-cement board, render and plasterboard  . Masonry substrates are generally porous, rough surfaces of varying degrees. While helpful in promoting adhesion, such porosity and roughness make it difficult to achieve repeatable thickness measurements.

. Masonry substrates are generally porous, rough surfaces of varying degrees. While helpful in promoting adhesion, such porosity and roughness make it difficult to achieve repeatable thickness measurements.

Masonry coatings are used for a variety of purposes, including cosmetic appearance, durability, abrasion resistance, and protection from elements such as moisture, salt, chemicals, and UV light. Common coatings for concrete include latex paints, acrylic paints, polyurethanes, epoxies, and polyesters.

The primer layer acts as an adhesion promoter, while the coat layer acts as protection from the surrounding elements. The PosiTector 200's ability to discriminate between layers of coating depends on the acoustic properties of adjacent layers, the thickness of individual layers, and the coating process itself.

The main purpose of measuring the thickness of concrete coatings is to control coating costs while ensuring adequate protective coverage. Commercial contracts often require an independent inspection of work upon completion.

A non-destructive testing method that avoids the need for coating repair after inspection and saves time for inspectors and contractors.

Measurement difficulties

A destructive test method has traditionally been used to determine coating thickness on masonry substrates, such as concrete. Coatings applied to concrete range from hard to soft, smooth to textured, and cover a wide range of thicknesses. The surface of concrete can be very rough so that thickness measurements can vary significantly.

Defelsko's workaround

The ultrasonic positector 200 C (standard or advanced) gauge is the ideal gauge for measuring coating thickness for most concrete applications. With a measuring range of 50~3800μm (2~150mils), this Thickness Gauge is recommended for those customers who need a single non-destructive measurement solution suitable for most applications. The ultrasonic positector 200 C requires little or no calibration for most applications. Figure 1 provides a profile showing representative large aggregate concrete coatings with film thicknesses ranging from 125 to 375 microns (5 to 15 mils), which is a desirable coating thickness as measured with the PosiTector 200 C.

Ultrasonic positector 200 B measuring instrument is a satisfactory thickness measuring instrument for measuring coating thickness from 13 to 1000 μm. While not specifically designed for measuring concrete, a simple calibration adjustment of the B-probe can demonstrate improved repeatability when measuring hard and thin coatings on smooth surfaces. Figure 2 shows the applications where the PosiTector 200 is recommended for measurement.

If the concrete surface is smooth, but uneven, or rough and porous, one would expect the measurements to vary accordingly.

Where paint has flowed into pores or cracks may appear abnormal when measured when inspected with a magnifying glass. For example, in Figure 3, the thickness results measured at point A of the substrate are significantly different from those measured near point B. When analyzing results, it is up to the user to compare the measurement to specification parameters or expected thickness. When calculating, it may be necessary to omit some results.

For the application shown in Figure 4, where there is a rough substrate and a rough coated surface, it may be necessary to take several readings in separate small areas, calculate the average reading, and then compare the values. These averages can then be compared to specification parameters. Samples were tested in destructive testing as shown in Figure 4, and a variation of 1 to 3 mm (40 to 115 mils) over a ¼ diameter area was determined.

how to measure

The principle of ultrasonic thickness measurement is to use a probe (transducer) to send an ultrasonic vibration to the coating, and the surface of the coating needs to be coated with coupling agent for assistance. Each Thickness Gauge includes a 4 oz bottle of regular water-based glycol gel. Alternatively, a drop of water can be applied as a couplant on smooth, horizontal surfaces.

After the couplant has been applied to the coated portion of the surface, place the probe on a flat surface. Press the start measurement key (see Figure 5). Lift the probe when you hear the double beep and the last measured value will be shown on the display. By continuing to hold the probe on the surface, a second reading can be taken at the same spot. When finished, wipe clean the probe and coated surface with a paper towel or soft cloth.

Graphics mode (positector 200 advanced models)

The PosiTector 200's screen on the right can display a graphic representation of the ultrasonic pulses passing through the coating system. This powerful tool enables the user to better understand what the gage is seeing on the coating surface.

Fig. 67: Left: PosiTector 200 C3 showing graphic mode; Right: PosiTector 200 C3 showing memory mode

PosiTector 200

Defelsko Positector 200 Ultrasonic Thickness Gauge is a satisfactory Thickness Gauge for measuring the coating thickness of various non-metallic substrates.

Two models for measuring masonry coatings:

1. PosiTector 200 C1 is an economical and common solution for measuring the thickness of total coating systems.

2. PosiTector 200 C3 can simultaneously measure the thickness of the total coating system and the thickness of up to three individual layers in the coating system. It also features graphical displays for detailed analysis of the coating system.

Each PosiTector 200 comes complete with probe, rubber protective holster belt clip, couplant, 3 AAA batteries, instruction manual, nylon shoulder strap carrying case, NIST traceable calibration certificate, and a two (2) year warranty.

Dimensions: 146 x 64 x 31 mm (5.75 x 2.5 x 1.2")

Weight: 165 grams (5.8 ounces) without battery

Conforms to ASTM D6132 and ISO 2808 standards.

Remarks: This article comes from Defelsko and is professionally translated by NBCHAO Mall. Please indicate when the translation is reprinted.

- 1Principle, Function, Application and Selection of Multifunctional Ultrasonic Thickness Gauge

- 2Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 3Principle, Application and Type Selection of Ultrasonic Thickness Gauge

- 4Principle, Application and Selection of Ceramic Ultrasonic Thickness Gauge

- 5The Principle, Application and Precautions of Copper Plate Ultrasonic Thickness Gauge

- 6Principle and Application of Ultrasonic Thickness Gauge

- 7Measure gloss with a PosiTector GLS gloss meter

Defelsko

- 8Measurement principle and influencing factors of high temperature ultrasonic Thickness Gauge

- 9Principle of Portable Ultrasonic Thickness Gauge

-

-

-

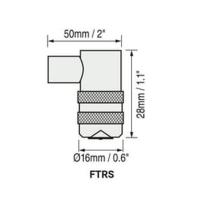

Defelsko FTRS Thickness Gauge Probe$ 888.00

-

-

-