Common faults and treatment methods of compressors

(1) Low gas production

If it is found that the pressure generated by the compressor is always low and cannot meet the work needs, it may be caused by a large amount of gas consumption and low output. At this time, consideration should be given to adding a compressor or changing to a compressor with a larger gas production capacity.

(2) Suction valve failure

The simple way to check whether the suction valve is faulty is to remove the inlet and the filter, and then put the palm of your hand against the suction port. If the hand is sucked tightly to the suction port, it means that the suction valve is working normally. If it is not If the suction is tight and it is pushed back, or if you feel that the suction force on your hand is changing, it means that the suction valve is not closed properly. Due to the air leakage of the suction valve, the air does not enter the pressure vessel through the discharge valve, but through the suction valve. It is discharged again, so the gas production efficiency is low. As long as there is a slight leakage of the suction valve, the gas production efficiency will be reduced, so if the suction valve fails, it must be repaired in time.

(3) The inner diameter of the gas delivery pipe is too small

If the inner diameter of the gas pipeline is not large enough, it will cause too much pressure drop during the gas transmission process. In order to make the pressure drop on the gas pipeline as small as possible, a pipeline with a larger inner diameter should be used as much as possible. Generally, the minimum inner diameter of the main air pipe should not be smaller than the inner diameter of the compressor exhaust port, and the length and inner diameter of the pipe should match the power of the motor. The recommended pipe specifications are shown in Table 3-10. When setting up a long main line, in order to ensure smooth air supply, a certain slope should be maintained throughout the entire process, and drainage devices should be installed at all low points of the pipeline to drain the condensed water in time to prevent it from hindering the delivery of compressed air.

In the case that the pipeline cannot be replaced, in order to solve the problem of insufficient gas supply, another compressor can be added, or the gas supply system can be made into a closed-circuit circulation form and an additional gas storage container can be added, which is beneficial to the pressure of the pipeline. control.

(4) Leakage

The phenomenon of compressed air leakage in the air distribution system will not only cause unnecessary waste, but also cause insufficient air supply pressure. Due to seasonal temperature changes and other reasons, air leakage will occur at joints and pipe connections in the pipeline during the conversion process between cold and heat. In addition, the use of quick-loading and detachable pipe joints, pressure relief valves and drain valves are worn, which also causes leakage. s reason. The simple way to check the leakage of the gas distribution system is to use a brush to dip soapy water and apply it to all connection points to see if there are bubbles. The economical way to solve the leakage is to maintain the pipeline regularly and replace the leaking valves and valves in time. connectors.

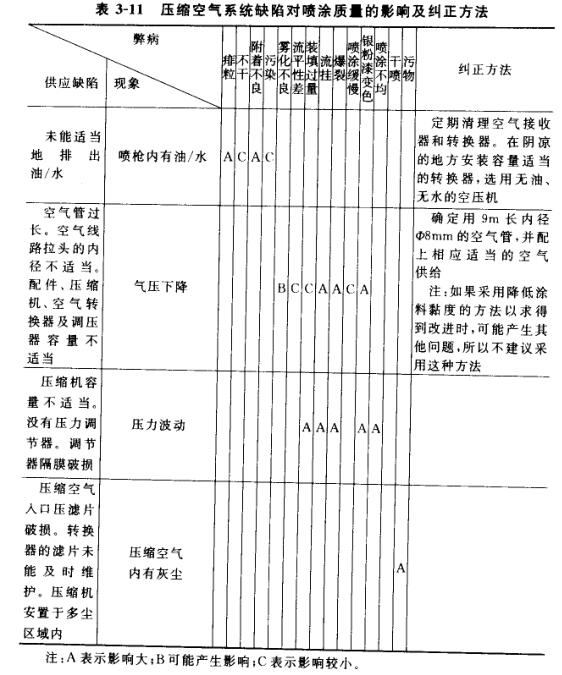

See Table 3-11 for the impact on the spraying quality due to the defects of the compressed air system and the corrective methods.

Operating an Air Compressor system is generally safer, but there can be unsafe hazards if insufficient attention is paid. Things to pay attention to include: cut off the power supply and unplug the power plug when performing maintenance on the equipment; do not touch the working parts with your hands, because the high-speed rotating parts will hurt the human body and the temperature of the compressor is extremely high when it is working, be careful not to contact the skin , to avoid burns; be careful when releasing the high-pressure gas, and the action should not be too violent, and prevent the high-speed airflow from blowing dust and foreign objects to hurt people.

- 1Principle, structural characteristics and application of piston Air Compressor

- 2Basic Principle and Application of Permanent Magnet Air Compressor

- 3How does the Air Compressor work?

- 4What is the structure of the Air Compressor?

- 5Air Compressor troubleshooting

- 6How to maintain the Air Compressor?

- 7Five steps to choosing the right Air Compressor

- 8What kind of Air Compressor do you generally choose for air Spray Gun spraying?

- 9Air Compressor selection of Fusheng