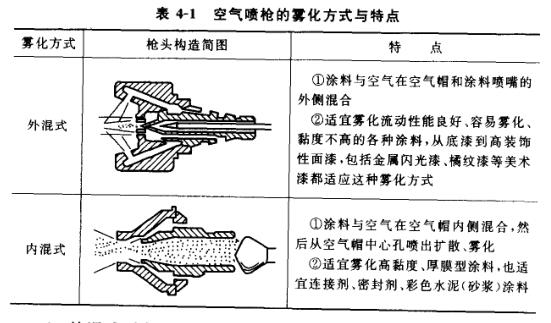

Atomization method and characteristics of air Spray Gun

There are two types of Spray Gun atomization methods: external mixing and internal mixing. Both use the rapid expansion and diffusion of compressed air to atomize the paint, but the atomization methods are different and the purposes are also different. The external mixing type can be used in suction and pressure feeding Spray Guns, and the internal mixing type can only be used in pressure feeding Spray Guns. The two atomization methods and characteristics of the air Spray Gun are shown in Table 4-1.

1. External mixing atomization

The most widely used atomization method is the external mixing type, because it can produce a good coating effect as long as it is controlled properly. The working principle of the external mixing atomizing Spray Gun is shown in Figure 4-1o. Compressed air is ejected from the center hole of the air cap, forming a negative pressure zone at the front of the paint nozzle, so that the paint in the paint container is sprayed from the paint nozzle and immediately enters the high-speed compressed air flow, causing the liquid-gas phase to diffuse rapidly, and the paint is covered by particles. Fly out in the form of mist.

External-mix atomization uses an external-mix air cap.

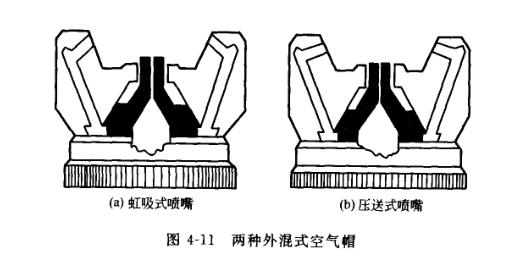

(1) External mixing air cap The external mixing air cap used for suction (siphon) Spray Gun and pressure feed Spray Gun is shown in Figure 4-11. Among them, the paint nozzle of the suction nozzle [Figure 4_11 (a)] protrudes from the surface of the air nozzle, and the opening angle of the side nozzle is also different from that of the pressure feeding type, because only in this way can a hole be formed on the end surface of the suction nozzle. Vacuum the paint out.

Since the pressure feeding type [Figure 4-11(b)] does not need to form a vacuum like the suction type feeding nozzle, the required atomizing air pressure can be lower. In contrast, the air-side nozzle on a pressure-fed air cap has a smaller angle of inclination, and there are additional air holes in the air cap that can be used to keep the nozzle surface clean.

Compared with the two forms, the pressure-feed atomization spraying rate is higher, the speed is faster, and it is cleaner. The suction-type atomization is more suitable for a small amount of spraying, such as in the car repair shop. The type of air cap can usually be identified by the letter printed on it, "s" for use on suction guns, and "P" for air caps used on pressure feed guns.

(2) Precautions for use

①Advantages. The paint film produced by external mixing spraying is finer, so this Spray Gun is suitable for coatings that require higher decorative effects such as furniture and cars. The external mixing air cap has great flexibility to adjust the spray shape and atomization degree. Use the suction external mixing air cap to draw paint up and atomize it.

②Disadvantages. The use of external mixing atomization requires more air, and higher air pressure is required during operation, especially when the compressed air and paint pressure are not controlled properly, a large amount of overspray and rebound will occur, which not only affects the spraying effect, but also wastes a lot of paint .

③ Replacement of the air cap. Pressure-fed air webs cannot be used on suction-fed guns with siphon feed. Suction-type air nozzles can be used on pressure-feed Spray Guns, but their atomization pattern diameters are smaller. In the pressure-feeding spraying, the suction-type air cap can be used to spray the paint with high viscosity. The suction air cap is only suitable for small size conventional spraying and painting. High production rates require the use of pressure-feed air caps.

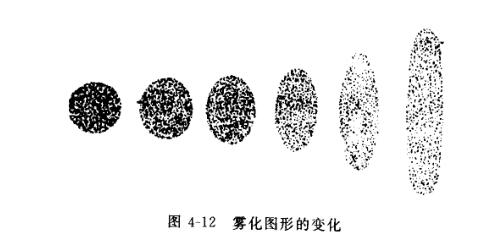

④ Changes in the atomization pattern. Using the external mixing air cap and fine-tuning the paint pressure and air pressure can get spray patterns of different shapes from round to oval, as shown in Figure 4-12. When the air pressure and paint pressure are basically kept constant, the amount of paint sprayed on the workpiece per unit time should be fixed. However, as the atomization pattern changes from a circle to an ellipse, its area continues to increase, so the coating is gradually thinning, and the overspray produced when the oval spray is formed is more than that of the circular spray, and the solvent volatilizes. The amount is also large, and the paint loss is more. Therefore, attention should be paid to the influence of the change of the atomization pattern on the spraying effect.

2. Internal mixing atomization

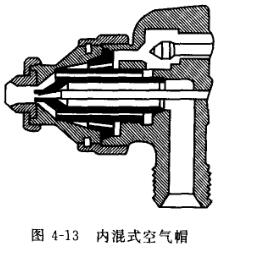

(1) The structure of the internal mixing air cap is shown in Figure 4-13.

(1) The structure of the internal mixing air cap is shown in Figure 4-13.

With internal mixing atomization, compressed air and paint are mixed in the internal cavity of the air cap prior to spraying. There are two types of internal mixing air caps: circular spray holes and long strip spray holes. When the paint is sprayed from the air cap, it is distributed in a fan shape, and its shape is determined by the size and shape of the air cap.

Internal mixing atomization is very popular in the maintenance industry, because although this method of atomization cannot produce fine atomization effects, the internal mixing atomization of production capacity is very popular in the maintenance industry, because although this method of fogging It can't produce fine atomization effect, but its production capacity is very high, which is very suitable for the needs of most maintenance coatings. But this kind of air cap is not suitable for all types of paints. It is mainly suitable for the spraying of slow-drying paints. When spraying fast-drying paints, the nozzle holes will be clogged, so it is not suitable for use.

(2) Precautions for use

①This atomization method can only be used in pressure feeding system.

② Low air pressure and low hydraulic pressure should be used for spraying and precise adjustment of air pressure and paint pressure. In order to get a good spray effect, the air pressure and paint pressure at the Spray Gun outlet should be equal. Therefore, when operating, you should first open the air pressure valve to obtain high air pressure, then slowly increase the paint pressure, and then slowly reduce the air pressure to make the two pressures equal and obtain satisfactory flow and spraying effect. Do not open the paint flow valve first. If there is no atomizing air, the paint will enter the air passage of the Spray Gun and cause blockage.

(3) Advantages and disadvantages of internal mixing atomization

①Advantages. The internal mixing atomization has the advantages of small air consumption, low air pressure, less overspray and rebound, can use large-caliber nozzles for large paint output, and can atomize viscous paint, etc., and the cost of replacing the air cap is low.

②Disadvantages. When using internal mixing atomization, the atomized particles are often not fine, so it is not suitable for fine coating with high requirements; because the nozzle hole is prone to clogging, it is not suitable for spraying quick-drying paint. The control of the spray pattern is not good, because there is no other control method other than using different types of nozzles to control the spray shape and size. Since the nozzle is easy to wear, so

3. Choice of atomization method

When choosing an atomization method, the following factors should be considered.

(1) Type of paint

The type of paint used determines the atomization pattern and how it should be atomized. Some coatings are more suitable for external mixing, and some are more suitable for internal mixing.

(2) Air consumption during atomization

The air consumption of the selected air nozzle should be lower than the air supply of the Air Compressor. Only in this way can a sufficient supply of compressed air be guaranteed during atomization, otherwise the air supply cannot be satisfied. Practical experience shows that for electric Air Compressors, every 1hp (745.7W) increase in power can produce 4ft3 (0.113m3) more compressed air with a pressure of 1001b/in2 (689.476kPa). The greater the air consumption of the air cap, the greater the spraying ability of the paint and the faster the speed of covering the workpiece. See Table 3-8 for the air consumption of various pneumatic equipment when the air pressure is 100psi (689476Pa).

(3) The air cap and the paint nozzle need to be used together

Because not all air caps can be used with any type of material nozzle, choose the nozzle that can be used with it. Users can learn the correct nozzle collocation from the information provided by the equipment supplier. Each manufacturer of spraying equipment generally produces a variety of special paint nozzles, and introduces the special air caps that can be matched with them in the data.

(4) Atomization air pressure

It refers to the air pressure used in the atomizing Spray Gun. As the atomizing air pressure increases, the required air consumption will also increase. Generally, the information provided by the equipment manufacturer will indicate the gas consumption when the atomization pressure is 207kPa, 345kPa and 483kPa. Since the higher the atomization pressure, the greater the air consumption, and the greater the amount of atomized paint, so the air consumption of the air cap should match the air production capacity of the Air Compressor. For the air cap with small air consumption (air consumption), it can be equipped with a small Air Compressor, and for the nozzle with large air consumption with multiple spray holes, it should be equipped with a high-power Air Compressor.

- 1Application and classification of lame plating technology

- 2Types of Spray Guns commonly used

- 3How to properly operate and maintain the Spray Gun?

- 4Why does the coating have orange peel defects? How to solve sagging and leakage?

- 5What are the tips to prevent sand inclusion and dry spray of paint film?

- 6The relationship between Spray Gun caliber, paint viscosity and coating type of electric airless sprayer

- 7Spraying of power tools - Spray Guns

- 8Several solutions for double coating

- 9Basic knowledge of Spray Gun: the relationship between air and paint