Airspraying common faults

The failures that occur during spraying can be divided into two categories: incomplete spray pattern and Spray Gun failure.

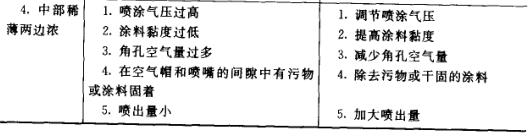

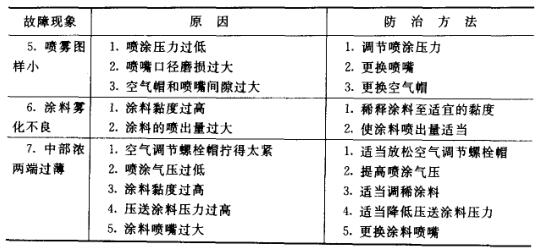

See Table 4-2 for the causes and prevention methods of incomplete spray patterns during air spraying.

The common faults of the air Spray Gun in use mainly include the following:

(1) The cause of this phenomenon may be a problem with the needle valve due to the leakage of paint at the front end of the nozzle. There is dirt on the contact surface between the nozzle and the needle valve, or the contact is not sealed, and the needle valve is damaged. Therefore, the inside of the nozzle and the needle valve should be cleaned, and the damaged needle valve should be replaced if necessary. It may also be that there is a problem with the needle valve gasket and needle valve spring. If the needle valve ring is too tight to make the needle valve move inflexibly, you should adjust its tightness. If the needle valve spring is damaged, you should replace it in time.

(2) The air valve of the Spray Gun is not well sealed. The tightness of the air valve gasket should be adjusted, and the air valve should be removed to remove the dirt. If the air valve or the air valve spring is damaged, it needs to be replaced in time.

(3) Unsmooth air outlet after the machine is switched on indicates that the air passage is blocked, and the air filter, air duct and air cap air hole should be checked to remove attached foreign objects.

(4) Paint leakage at the needle valve gasket is caused by the needle valve gasket being too loose or damaged, and the tightness should be adjusted or replaced with a new one.

(5) Common disadvantages of coatings formed by spraying

The common disadvantages of coatings caused by improper spraying operations are mainly as follows

1. Hanging

The paint sprayed on the vertical surface flows downward, causing uneven streaks and flow marks on the coating film. Among them, the phenomenon of partial vertical flow of the coating and uneven thickness ripples during the period from coating to drying is called sinking, and the phenomenon that the coating accumulates on the vertical surface and edges of the object to form obvious flow marks and solidifies is called sagging. A large area of sag is called flow.

The cause of sagging may be improper spraying operation, incorrect gun holding method, uneven spraying; low viscosity of paint, slow volatilization of solvent contained in paint; too thick coating formed by one spraying; low ambient temperature, etc. In order to solve this disadvantage, on the one hand, it is necessary to improve the proficiency of the spraying operation to make the coating as uniform as possible; on the other hand, to select the appropriate type and quantity of solvent, and to control the viscosity and temperature of the coating.

2. Exposed bottom (poor bottom cover)

The phenomenon that the painted surface is not painted due to missing coating is called exposed bottom, and the phenomenon that the bottom color is not covered due to thin coating film or poor covering power of paint is called poor bottom covering. During spraying construction, the viscosity of the paint is low, and the formed coating film is thin; the surface of the object to be coated is complicated, and the coating is not carefully sprayed, which will cause this phenomenon. In order to prevent this phenomenon, in addition to choosing a paint with strong hiding power and stirring it thoroughly before use, it is also necessary to operate quickly and carefully when spraying to prevent the phenomenon of missing coating, and each coat of paint should reach the specified spraying thickness.

3. Bite up

涂面漆后底漆层与工件表面脱离并产生皱纹、胀起、起泡等现象称为咬起。在喷涂硝基漆等含强溶剂涂料时容易发生这种现象。造成这种现象的原因是涂层未干透就涂下一道漆;涂层过厚或底涂层对面漆中的溶剂耐性差。解决的办法是一定等底漆层干透后再涂面漆,选用合适的底漆和与之配套的面漆。

4.橘皮

喷涂后不能形成平滑的干涂膜面,而呈现类似橘皮的凹凸状现象称为橘皮。产生这种现象的原因可能是:使用的涂料黏度大、流平性差;喷涂使用的压缩空气压力低,出漆量过大导致雾化不良;喷涂时枪件距离太远,环境温度过高,溶剂挥发过快。为解决这一问题,应从选用挥发性能合适的溶剂,在涂料中添加流平剂,调整好枪件距离,一次喷涂达到规定厚度,选择合适的压缩空气压力和出漆量及雾化性能良好的喷涂工具几方面下功夫。

5.落上漆雾

喷涂过程中漆雾飞溅或落在被涂物表面或涂膜上,影响涂膜的光泽和装饰性的现象称为落上漆雾。造成这种现象常是因为喷涂操作不正确,喷件距离太远,相邻被涂物工件之间的距离太近或不需涂漆的表面未加遮盖造成的。在喷涂室中喷涂时,室内气流混乱或风速太低也会造成这种现象发生。所以应纠正不正确的喷涂操作方式,调整枪件距离;在相邻被涂物之间留足距离并遮盖好不需喷涂的表面。在喷涂室中喷涂时,应使气流保持一定方向,风速在手工喷涂时应保持在0.5m/s以上。

6.颗粒

The appearance of granular substances on the surface of the coating film will seriously affect the appearance, which is the main reason for the high repair rate of advanced coatings such as cars. In order to eliminate the particles on the coating film, use 1500# water sandpaper to polish and remove them. If the particles are large and many, use 800# water sandpaper to polish and then spray again. The key to eliminating particles is to prevent foreign particles from entering the coating. In order to eliminate dust from the working environment, various measures should be taken to keep the workshop tidy, such as partitioning the layout of the workshop, keeping the pre-treatment sections such as grinding away from the spraying work area, brushing the floor paint on the car floor to prevent dusting, and regularly Cleaning, humidification of workshop air, reducing dust, etc. For the particles from the paint, the paint should be fully stirred and diluted before spraying, and then filtered. The top coat should be filtered with a 180-mesh fine mesh to remove the flocculated and coarse paint or insoluble resin particles. In order to prevent all kinds of dust from being brought into the coating film by electrostatic adsorption on the surface of the workpiece, blow the workpiece with clean compressed air or wipe the workpiece with a sticky rag before spraying, and take corresponding measures to reduce the fiber content of work uniforms, spray booth filter materials, and dry rags. contamination of workpieces.

- 1Application and classification of lame plating technology

- 2Types of Spray Guns commonly used

- 3How to properly operate and maintain the Spray Gun?

- 4Why does the coating have orange peel defects? How to solve sagging and leakage?

- 5What are the tips to prevent sand inclusion and dry spray of paint film?

- 6The relationship between Spray Gun caliber, paint viscosity and coating type of electric airless sprayer

- 7Spraying of power tools - Spray Guns

- 8Several solutions for double coating

- 9Basic knowledge of Spray Gun: the relationship between air and paint