Introduction to the principle and characteristics of lame plating

1. The working principle of flame spraying method

1. The working principle of flame spraying method

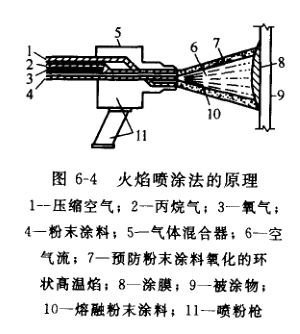

The main equipment used in flame spraying is the flame Spray Gun , and its structure is shown in Figure 6-4 . Compressed air sprays special powder coatings such as metal powder or thermoplastic powder from the central nozzle of the powder Spray Gun , and cooling air is sprayed around the concentric circle of the powder spray tube , and passes through the acetylene sprayed from the periphery of the nozzle at high speed. or propane and other combustion gases and oxygen to form a flame area , making the paint into a molten state , and then sprayed and adhered to the surface of the workpiece. The control of the fluid is to use the control panel to adjust the appropriate ratio of cooling air and flame , so that the powder coating just becomes a molten body when it is sprayed on the surface of the workpiece . If the heat energy provided by the flame of the powder Spray Gun is not enough to make the powder coating turn into In the molten state , the powder coating should also be preheated before entering the Spray Gun. The workpiece needs to be preheated to 200~250 ° C before it can be flame sprayed. The preheating temperature is related to the type of powder coating used and the heat capacity of the object to be coated. Generally, the surface temperature of the workpiece should be above the melting temperature of the powder coating.

2, the characteristics of the flame spraying method

The advantages of the flame spraying method are: the coating equipment used is simple, the price is low, the utilization rate of the powder coating is high, a thick coating film with a thickness of 500 μm can be formed after one spraying, and no coating recovery system is required. Because spraying is carried out at high temperature, it can work in low temperature or high relative humidity environment, which is very suitable for coating and repairing large metal workpieces on the job site.

However, it has the disadvantage that the spraying thickness is not easy to control, so it is difficult to guarantee the quality when spraying super-large workpieces or complex-shaped workpieces, and the flying loss of coating powder is serious during construction. It is necessary to set up a dust collection device at the work site, and the operators must wear protective masks. dust mask.

3. Application of flame spraying

Flame spraying is mainly used in the coating or repairing of chemical equipment and mechanical parts to form anti-corrosion coatings, wear-resistant coatings or general decorative coatings. For example, in the shipbuilding industry, the flame spraying method is often used to spray powder coatings such as polyamide (nylon 1010) on handles, pads, shrouds and impellers. The coating film formed by nylon 1010 not only has good wear resistance , hardness, impact resistance, and has good heat insulation, sound insulation and insulation properties, so use it to spray and repair worn parts, and then perform appropriate machining to get workpieces with good performance.

At present, there are portable effective flame spraying machines and multifunctional flame spraying devices developed in our country. These devices can be used to spray ceramic powders with high melting points, as well as various metal alloy powders and plastic powders. The construction speed of flame spraying equipment developed abroad has reached an effective rate of 18~36m2/h.

- 1Powder Coating Spraying FAQ

- 2Under what conditions can electrostatic spraying equipment be selected?

- 3Main points of container lame plating

- 4Advantages of coating powder and its production process

- 5Production method of metal coating powder commonly used in production process

- 6How to solve the color difference of real stone paint from production and construction

- 7Floor painting method of painting

- 8High pressure airless lame plating

- 9Car painting topcoat lame plating