Introduction of electrostatic spraying system for coating powder

1. Composition of electrostatic spraying equipment for powder coatings

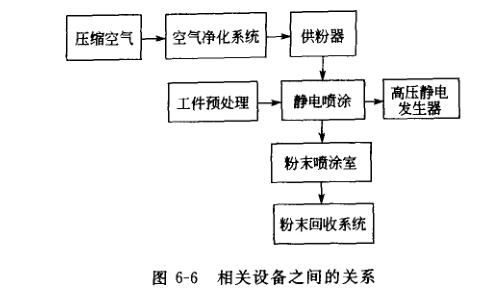

The technological process of powder electrostatic spraying is generally: pre-painting treatment → protection of unpainted parts → spraying → baking and curing → trimming and removal of defects. The relationship between related devices can be shown in Figure 6-6.

The electrostatic spraying equipment for powder coatings is shown in Figure 6-7. Among them, the compressed air supply and purification system, the workpiece pretreatment system are basically the same as those used in solvent-based paint spraying. Therefore, this section mainly introduces the differences from solvent-based paint spraying, including the structural performance of powder feeders, electrostatic powder Spray Guns, high-voltage electrostatic generators, powder spray booths, and powder recovery systems.

2. Covering and protecting parts that do not need to be sprayed

Before electrostatic powder spraying, shielding protection measures should be taken for parts that do not need to be coated on the workpiece. The parts and methods that often need to be protected are as follows.

(1) The inner cavity of the valve part often needs to be coated with paint as a protective layer, but the parts in contact with the valve body on both sides of the valve often need to be shielded during spraying. Cured powder coatings are easy to remove.

(2) The thread on the threaded workpiece often needs to be shielded during spraying. The internal thread can be blocked with a screw of the corresponding specification, or the internal hole can be directly blocked with a tight-fitting cylindrical thread interface. Cylindrical workpieces such as external threads can be taped or shielded with a sleeve.

(3) Other special parts on other workpieces that need to be shielded can be coated with liquid silicone rubber. After it is cured at room temperature, powder electrostatic spraying can be carried out. Since the adhesion between silicone rubber and powder coating is very poor, it is easy to clean . For a large area that does not need to be sprayed, it can also be covered with paper, and the paper can be removed after spraying.

- 1Determination of thermal plasticity Resin melt flow rate

- 2Molecular weight and distribution characteristics of polyester resin in thermosetting powder coatings

- 3Density Determination Method and Application

- 4Determination method of cone-plate viscometer and its application

- 5Thermal plasticity polyvinyl chloride (PVC) powder coatings in highway engineering: technical requirements and inspection methods

- 6Determination of compatibility of powder coatings: methods, effects and applications

- 7Evaluation of flowability of powder coatings: key factors and significance

- 8Evaluation and Application of Optical Properties of Powder coatings

- 9Importance of powder coatings curing degree and detection method