Principles for choosing a lame plating process

When choosing the coating and its process for spraying, the following factors need to be considered.

1. Purpose and requirements of painting

Although the coating can have multiple functions at the same time, one of the functions is often required in particular, so when considering the selection of coatings, the main purpose of the coating should be considered. The purpose of coating the workpiece includes making it protective, decorative or have other special purposes. For the coating whose main purpose is to improve the protective performance, the coating is required to have a certain strength and protective ability, which can prevent mechanical damage, delay the corrosion of the substrate, and prolong the service life of the product. Coatings with excellent protective properties such as epoxy resin, phenolic resin, asphalt resin, polyurethane resin and silicone resin are usually selected. Generally, medium and high viscosity paint should be used, and the atomization degree of the paint is not too high when spraying. For the coating with decorative effect as the main purpose, in addition to requiring a certain protective performance, there are special requirements for the appearance and outdoor performance of the coating. The coating is required to have beautiful color, suitable gloss and good gloss retention. Generally, amino alkyd resin coatings, acrylic resin coatings and polyurethane (aliphatic) coatings with good outdoor performance can be selected. Moreover, when spraying, the viscosity of the paint should be lower and the atomization level should be higher. When the coating is required to have special purposes such as insulation, wear resistance, and lubrication, various special coatings should be considered.

2. The use environment of the coating

There are many factors that may affect the properties of the coating in the environment, such as climate change and regional hot and cold changes, which will cause the coating to expand with heat and contract with cold, resulting in blistering, cracking and peeling off. The radiation effect of ultraviolet radiation in sunlight will degrade and age the coating and deteriorate its performance. Oxygen, corrosive gases, acid-base salts and other chemical substances in the air will have various chemical reactions with the coating film to destroy it. Humidity and rain will cause the coating film to absorb water and swell and cause bubbling. The erosion of mold and other microorganisms in a humid and hot environment can directly damage the coating film. Mechanical effects such as sandstorms, stone impacts, friction, and collisions will abrade the coating film and cause cracking and peeling off. wait. Coatings used in different environments suffer from different destructive effects, so the appropriate coating should be selected according to the specific environmental conditions of the coating and the specific characteristics of the coating. The adaptability of the coating to the environment includes cold resistance, weather resistance, heat and humidity resistance, salt spray resistance, chemical corrosion resistance, oil resistance and water resistance, solvent resistance, wear resistance and impact resistance, etc. For example, the coatings used for outdoors are much more affected by sunlight, wind and rain, and temperature changes than the coatings used for indoor environments, so they are required to be resistant to ultraviolet rays and the atmosphere. The most important thing is the damage caused by friction and cleaning, so the requirements for wear resistance and washing resistance are higher. Coatings used in inland environments have high requirements for anti-sandstorm and climate change, while coatings used in coastal areas have high requirements for anti-salt spray, humidity and mildew resistance.

3. The nature of the workpiece substrate

Materials commonly used to manufacture objects to be coated include steel, non-ferrous metals, wood, plastic, leather, and the like. Due to the different physical and chemical properties of the surface of various materials, the adaptability and construction requirements of the coating are different. For example, most paints have strong adhesion to the steel surface, but poor adhesion to the surface of non-ferrous metals such as aluminum and zinc alloys. Primer method to improve paint adhesion. Since the wood surface is porous, the paint is easily penetrated and absorbed, so a pre-applied sealer is required to reduce paint consumption and avoid loss of gloss. The solvent in the paint often causes swelling or dissolution of the plastic, so the plastic needs to be treated with a special plastic primer or other measures before painting. Coating systems are designed for different materials. The corrosion resistance of steel is poor. Generally, it should be pretreated by phosphating and a multi-layer coating system of primer, topcoat and varnish should be used, and the surface of aluminum alloy has a layer of excellent protection. The performance of the oxide film, so it is enough to apply a varnish after painting the color paint, and the plastic does not have the problem of being corroded. The purpose of painting is mainly for decoration and anti-aging. The primer should also use a plastic-specific paint with the same flexibility as the plastic.

4. Construction conditions

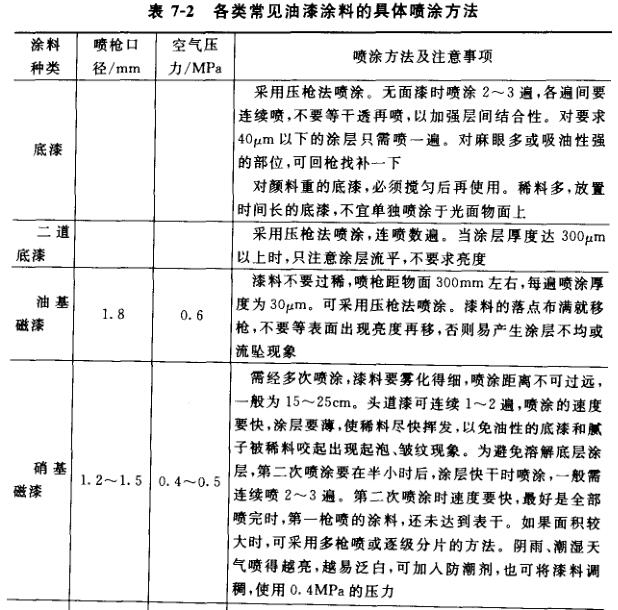

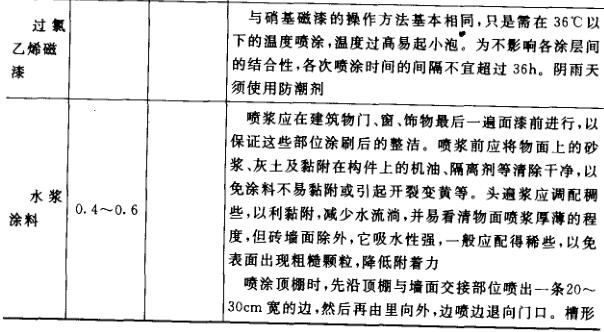

The construction conditions include the spraying method and the curing conditions of the coating film, and the appropriate coating should be selected according to the actual situation of the construction unit. If the construction unit does not have drying equipment, self-drying coatings such as thermoplastic acrylic coatings, perchlorethylene coatings, and nitro coatings or low-temperature curing coatings can be used. High-quality dry-cured coatings can be used when drying equipment is available. Different coatings, some are suitable for air spraying, some are more suitable for electrostatic spraying, and the same coating has different requirements for coatings when different spraying methods are used, so the spraying method should be selected according to actual needs. See Table 7-1 for the suitable spraying methods and drying conditions of various coatings. And as far as spraying is concerned, due to the different properties of the coating or the use of different coatings, the specific spraying methods are also different. When various paints are sprayed by air, the diameter of the nozzle, the air pressure used and the process characteristics are all different, as shown in Table 7-2.

5. Technical economy

Technical feasibility refers to the requirements for facilitating construction operations, ensuring ease of management during construction, and ensuring stable quality. It should not only reflect professionalism, but also ensure reliability, and should be selected according to the technical management level of the construction unit. The economy is comprehensively considered from the aspects of coating cost and construction cost, coating service life, and the influence of coating quality on product value. It should be ensured that the cost of the coating and the function and the price and function of the product itself match as much as possible. That is, on the premise of meeting the basic requirements of coating, the cost of coating should be reduced as much as possible. For example, the protective and decorative properties of car coatings are closely related to the quality and grade of the car, and the price of the car itself is also very high. Therefore, whether it is primer, intermediate paint or top coat, high-grade paint should be selected for car coating. For agricultural vehicles with low cost, the coating is only required to have a certain degree of protection and decoration, so the standard can be appropriately lowered when choosing a coating.

6. Environmental friendliness

Since solvent-based coatings contain a large amount of organic solvents belonging to VOCs, which seriously pollute the environment, try not to use them as much as possible. Instead, use water-based coatings, powder coatings, high-solid coatings, and light-curing coatings that are environmentally friendly. coating. Because they pollute the environment, they will produce huge social benefits. Although the use of these coatings will increase the cost in terms of material costs, but in terms of construction efficiency, coating utilization rate and coating performance improvement, it is possible to reduce the overall cost, so the promotion of environmentally friendly coatings in practice use is necessary.

7. Compatibility of coating

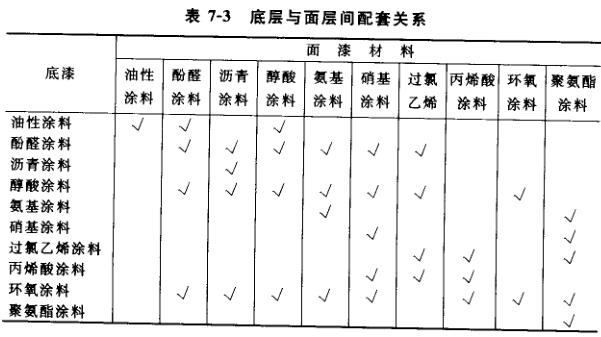

In the coating of high-end products, because a single coating often cannot meet various performance requirements at the same time, the protection and decoration of the product are generally designed according to the composite coating system, such as the car body according to its appearance. , Ordinary grade, using 5C5B, 4C4B, 3C3B and 2C2B composite coating systems (C is coating, B is drying, such as 5C5B is 5 coatings and 5 dryings). Composite coatings with excellent properties for steel products are also composed of primers, middle coats, top coats and varnishes. Products of other materials also have a certain composite coating mode. Since the coating is a multi-layer structure, the matching between the coatings is very important. If the matching is not good, there will be problems of weak bonding between the coatings and defects, so the coatings need to be used together. The law of compatibility is as follows: coatings with the same resin (film former) generally have good compatibility, but coatings with different paint bases are often not good enough. At this time, modification treatment is required to improve its binding force. Coatings with the same hardness and strength of the coating film generally have better compatibility. If the thickness of the underlying coating is too soft, it is prone to wrinkling and falling off. Topcoats containing strong polar solvents can cause "bottom-biting phenomenon" on the bottom layer with poor solvent resistance. Improve its solvent resistance by increasing the pigment and filler content in the primer.

In addition, the drying methods of each layer of coating film should also be consistent. The drying primer is matched with the drying topcoat, and the self-drying primer is matched with the self-drying topcoat. The drying conditions of each layer of the drying paint should also be consistent, so as to avoid the problem of excessive cross-linking of a certain layer of coating film leading to performance degradation and poor bonding with other coating films.

Since the primer focuses on protection and the topcoat focuses on decoration, the two types of coatings are often formulated with different base materials. There is also a question of whether these base materials are compatible, so it is best to use the same type of topcoat and primer. If the coating of the base material is not available, a coating composed of base materials that can be matched with each other should also be selected. The compatibility of different base materials is shown in Table 7-3.

- 1Analysis of gas turbine coating cupping performance

冯文;李正超;向旭东 - 《东方汽轮机》

- 2Lame plating technology

- 3How to choose car lame plating equipment?

- 4Application of Miscellaneous lame plating technology in medium coating and topcoat

- 5Lame plating process and equipment selection

- 6Introduction to the principle and characteristics of lame plating

- 7Process conditions for high voltage electrostatic spraying of coating powder

- 8Factors affecting the volatilization of manual lame plating solvent on workpiece

- 9Principles and characteristics of heating lame plating