Stirring device in emulsion paint Pigment and filler dispersion

Whether it is a pigment or a filler, when purchased, it is composed of secondary particles agglomerated from hundreds to thousands of primary particles. When mixing with the emulsion, whether the secondary particles of pigments and fillers are reduced to primary particles before mixing, or whether the secondary particles are directly added to the emulsion and then dispersed and mixed, the preparation method is obviously different. The former mixing method is called grinding pigmentation (grindingpigmentation), and the latter method is called dry pigmentation (drypigmentation) method. When the total amount of water in the formula is not enough to adopt the grinding and coloring method, you can add part of the emulsion to the water first, and then add the secondary particles of the pigment and filler to it for dispersion. After the dispersion meets the requirements, add the remaining emulsion and mix evenly , This method is called semi-dry coloring method.

The grinding and coloring method is to apply a large amount of mechanical energy to the secondary particles of pigments and fillers to depolymerize and disperse them in water to form a slurry, and then mix them with the base material. In contrast, the dry coloring method is to directly add the secondary particles of pigments and fillers to the base material for dispersion and stirring (stirrer). Agglomerated and dispersed states are different.

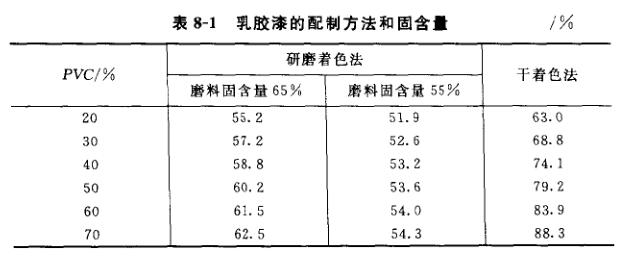

The solid content of grinding coloring method and thousand coloring method calculated under different PVIC are listed in Table 8-1. In the calculation, it is assumed that the solid content of the emulsion is 50%, the density of the polymer is 1.0g/cm3, and the average density of the pigment and filler is 2.8g/cm3.

Because the modulation of the abrasive in the grinding and coloring method is restricted by the viscosity, the solid content of the abrasive is generally below 7o% during beating. When the abrasive solid content is 65%, the paint manufactured by this method is within the practical PVC range listed in Table 8-1, and its solid content can reach up to about 62%. The solid content of coatings made by dry coloring can be as high as 88%. Regardless of the grinding coloring method or the dry coloring method, the solid content of latex paint increases with the increase of PVC.

As far as the dispersion state of the pigment is concerned, the deaggregation of secondary particles in the dry coloring method is not as sufficient as that in the grinding coloring method, and this tendency is more obvious when the pigment particles are smaller. Therefore, for glossy emulsion paints, they are generally produced by grinding and coloring methods.

Both the dry coloring method and the semi-dry coloring method require that the emulsion has good mechanical stability and does not break the emulsion during high-speed dispersion. Many emulsions can meet this requirement now.

For thick paints such as elastic latex paint, three-dimensional pattern finish paint and sand wall finish paint, because of its thick film thickness, it is easy to produce shrinkage cracks when it dries to form a film at -T. In order to avoid this tendency, it is often necessary to reduce the paint Water content, and try not to use too fine pigments and fillers. In addition, as a thick coating, it is required to apply a relatively thick thickness at one time, so it is also necessary to increase its solid content. This results in low water content of the thick paint, which cannot be produced by the grinding coloring method, but can only be produced by the semi-dry coloring method and the dry coloring method.

For thin-layer coatings and coatings with sufficient water content in the formula, the grinding coloring method should be used for production. When the grinding coloring method or semi-dry coloring method is used for production, after the pigments and fillers are dispersed, the emulsion should generally be slowly mixed. Add pigments and fillers to make paint, not vice versa.

- 1Comparison and Application of Magnetic Stirring and Mechanical Stirring

- 2Describe 4 Common Stirrers in detail

- 3What is a mixer? Applications, advantages and disadvantages of mixers

- 4How to prepare polymer blended solid film materials?

- 5Agitators and their classification

裴梦琛 - 《西北大学》

- 6Testing Factors Affecting the Drying Properties of Plastic Water-based Gravure Ink with Agitator

- 7What are the characteristics of an overhead mixer?

- 8Do you really know how to use an overhead blender correctly?

- 9How to choose your own suitable overhead mixer?

-

Qiwei CL-R magneticstirrer 1000ml$ 103.00

-

-

-

-

-