Dyne pen and dyne solution

For plastic flexible packaging factories, it is necessary to test the printing suitability with a dyne pen every time a new batch of film is imported, or on the printing machine, it is necessary to test every time a roll of film is replaced, because once the inspection is missed, the printing effect of the film will be damaged. Bad luck can bring unexpected losses.

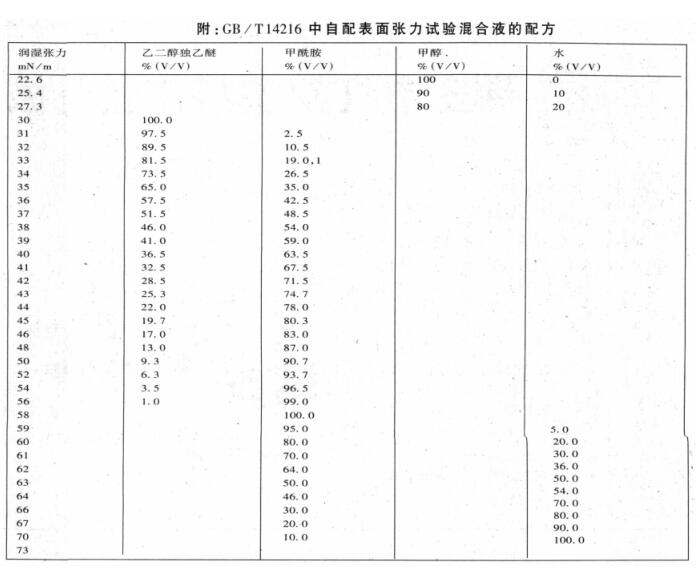

According to the requirements of GB/T14216 "Plastic Film and Sheet Wetting Tension Test Method", the solution is prepared according to the formula requirements in the attached table, and the surface tension of the film can be known by simply smearing.

Since it is so simple and convenient, why do most printers like to use dyne pens? What is the difference between dyne liquid and dyne pens?

An important reason is that the self-made dyne solution is difficult to operate. A client in Beijing added 0.03% Victoria Pure Blue to the 38 dyne liquid prepared according to the ratio in the attached table, and found that the effect was not good during the film test operation, so he took the liquid to Landmaker Company Test to detect that the actual surface tension is 43.7 dynes. What is the reason? After analysis, it may be the following reasons:

1. In the mixed liquid, the boiling point of ethylene glycol monoethyl ether is 135°C, and the boiling point of formamide is 210°C. The former volatilizes quickly, while the latter volatilizes slowly.

As a result, the ethylene glycol monoethyl ether component in the mixture decreases, the formamide component increases, and the surface tension of the mixture increases.

2. The polar group of formamide can absorb moisture in the air, which can cause moisture in the mixed liquid and increase the surface tension.

3. The purity of the reagent is not enough, and the basic surface tension is high.

Later, it was detected that the ethylene glycol monoethyl ether with the label number 80062118 purchased by the company had a surface tension of 32.3 dynes. According to the analysis of the sample, the increase of the surface tension is caused by the combined action of the above reasons.

Let’s look at the dyne pen again. Taking the Italian DY-L series dyne pen as an example, its ink is generally composed of four parts: solvent, film-forming agent, auxiliary agent and pigment dispersed in it.

1. The solvent is an organic high-boiling point solvent, generally a solvent, which can stabilize the chemical components, and the solvent is required to be non-toxic.

2. The film forming agent is also a thickener, which is an organic resin dissolved in a solvent. Its addition can turn the solvent into a colloid. On the one hand, it can adjust the surface tension of the liquid. On the other hand, when the solvent volatilizes, it can form a layer on the surface. The thin film slows down the volatilization speed of the solvent and increases the service life of the Dyne pen.

3. Auxiliaries include surfactants, defoamers, preservatives, lubricants and anticorrosion agents, dispersants, anti-drying agents, etc. Dyne pen inks with different dyne factors are mainly adjusted by additives.

4. Pigments are well known and are used for coloring.

Before each batch of dyne pens is produced, the ink must be checked for clarity, specific gravity, pH value, surface tension, viscosity and color. The final appearance is required: the writing performance is fine and smooth, without a feeling of drawing, and the edges are neat.

It can be seen that the dyne pen is essentially different from the self-prepared dyne liquid, and it can be regarded as "chunlanqiuju" for surface tension purposes. Customers can choose according to their own needs.

-

-

Fengzhiyue 30 Dyne pen$ 84.00

- 1Application of Dyne pen in surface tension measurement

- 2Dyne pen in film printing

- 3Dyne pen test method

- 4How to Use a Dyne Pen to Determine Surface Energy

- 5How to Ensure the Accuracy of the Dyne Pen Test

- 6Dyne Pen Controls Surface Tension of Printed Coatings

- 7Four simple steps to use the dyne pen correctly

- 8Dyne pens and test fluid -- how do they work?

- 9What is dyne level?