Discussion on Several Problems in Testing of Waterproof coatings

Several problems that should be paid attention to in the testing of waterproof coatings are analyzed, including the environmental conditions of the laboratory, the number of brushing times of the coating film, the stirring method, the curing system and the points for attention in the tensile performance test. It is pointed out that the standards for waterproof coatings should be as uniform and clear as possible for the above problems.

In recent years, the country has successively issued and updated various waterproof coating product standards, standardized the production and engineering application of waterproof coatings, greatly improved the product quality of waterproof coatings, and the performance testing of waterproof coatings has become more and more popular. attention. Therefore, it is the basic requirement for inspectors to accurately understand and grasp the national and industry standards and ensure the scientific, accurate and notarized testing data. This paper puts forward several issues that should be paid attention to in the detection of polyurethane waterproof coatings, polymer cement waterproof coatings and polymer emulsion building waterproof coatings, which are currently used most in waterproof coatings, for discussion. The waterproof coating standards involved in this article are: GB/T16777-2008 "Test Methods for Building Waterproof Coatings", GB/T19250-2003 "Polyurethane Waterproof Coatings", JC/T864-2008 "Polymer Emulsion Building Waterproof Coatings" and GB/T19250-2003 "Polyurethane Waterproof Coatings", T23445—2009 "Polymer cement-based waterproof coating".

1 Matters needing attention in the process of sample film formation

In the performance testing of waterproof coatings, most of the testing items are to evaluate the quality of waterproof coatings by testing the physical and mechanical properties of the membrane after the sample is formed into a film, such as tensile strength, elongation at break, impermeability, and low temperature flexibility. , heating expansion rate and tensile properties after heat aging, acid-base salt treatment, etc., which are the differences between the performance testing methods of waterproof coatings and waterproof membranes. Therefore, the film-forming quality of the sample directly affects the final test result of the waterproof coating, and is a key factor in the performance test of the waterproof coating. The film quality of the sample is closely related to the environmental conditions of the laboratory, the number of times the film is painted, the method of stirring and curing.

1.1 Laboratory environmental conditions

The temperature and humidity in the laboratory play an important role in the film-forming quality of waterproof coatings, which is mainly during the curing process of the coating film. For example, for polymer cement-based waterproof coatings, a dry environment can accelerate the evaporation of water, which is conducive to the film formation of the coating; a humid environment is conducive to the hydration of cement. For one-component polyurethane waterproof coatings, because they mainly rely on the absorption of moisture in the air to undergo hydration reactions to achieve the purpose of curing, the humidity level directly affects the speed of its reaction and curing. For two-component polyurethane coatings, when the temperature rises, the effect of amine compounds catalyzing the reaction between isocyanate and water is effective, thereby releasing more carbon dioxide and forming bubbles in the coating film, which will cause premature fracture and low-temperature bending during the tensile test During the test, cracks and the like are formed due to air bubbles.

In addition, the temperature in the laboratory is too high, and the coating film produced is often a spongy loose structure, resulting in an increase in the measured tensile strength and a decrease in the elongation at break. For different materials, the tensile strength and elongation at break vary in different magnitudes. The author once found in the test that when the temperature difference in the laboratory is 5°C, the maximum difference in tensile strength is 28%, and the maximum difference in elongation at break is 35%, which directly affects the judgment of product qualification. It can be seen the importance of controlling the laboratory temperature and relative humidity.

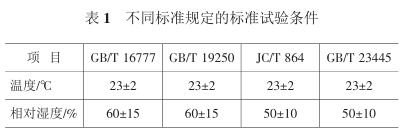

The above-mentioned 4 standards respectively stipulate the standard test conditions of the laboratory, including temperature and relative humidity, see Table 1.

It can be seen from Table 1 that the laboratory standard test conditions stipulated by different standards are slightly different. In actual work, we can choose a common temperature and humidity range (such as (23 ± 2) ℃, 45% ~ 60%) as the laboratory environmental conditions to control, so that we can meet the requirements of different standards.

1.2 The number of brushing times of coating film

As we all know, on the premise of meeting the thickness requirements of the waterproof coating film, the more times of coating, the better the compactness of the film. Observing the cross-section of the coating film with a magnifying glass, it is found that the bubbles in the coating film with a thin coating (thickness not exceeding 0.5mm) are small and closed; The air bubbles are relatively large, and sometimes the air bubbles almost penetrate the entire coating, but the surface of the coating seems dense. It can be seen that different coating methods will lead to different test results of waterproof coating products and affect the judgment of product qualification.

The waterproof paint stirred in the same pot was coated with samples 2 times and 3 times respectively. Under the same curing system, the two test data of untreated tensile strength and elongation at break were quite different. Therefore, it is recommended that each standard clearly stipulate the number of coatings, such as coating 2 times during factory inspection, and 3 times during type inspection or arbitration inspection, and the final thickness should be controlled at (1.5±0.2) mm. This can not only shorten the test time, but also ensure the technical indicators in the standard and improve the quality of testing.

1.3 Stirring method

Stirring methods include the type of mixer (especially the type of mixing blade), stirring speed, stirring time and selection of stirring pot.

1) The type of mixer is not clearly specified in the standard. There are various types of mixers available on the market , mainly in the different forms of the blades of the mixers, and the mixers used by different manufacturers' laboratories and testing institutions at all levels are different.

2) The stirring speed is not clearly specified in the standard. The mixing speed of the mixer is mostly divided into three levels: high, medium and low. For polymer cement waterproof coatings, low-speed stirring should be used, because the stirring speed is too fast, the paint is easy to mix air bubbles, and the polymer chain segments in the polymer may also be cut off, which will affect the film quality and test results.

3) The size and shape of the stirring pot are not clearly specified in the standard. The current waterproof coating standard simply stipulates the time of mechanical stirring (5min), but does not specify the size and shape of the stirring pot in detail.

Therefore, the author suggests that you can refer to the cement paste mixer specified in JC/T729-2005 "Cement Paste Mixer" and the "cement paste mixer" specified in 7.2 of GB/T1346-2001 "Cement Standard Consistency Water Consumption, Setting Time, and Stability Test Method" 7.2. Mixing method of clean slurry" to formulate the mixing method of waterproof coating.

1.4 Coating film maintenance system

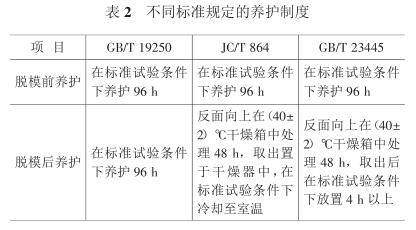

The maintenance systems of different waterproof coatings are shown in Table 2. For polymer cement-based waterproof coatings and polymer emulsion architectural waterproof coatings, after 96 hours of curing under standard test conditions, the coatings have not been fully cured, and there will still be residual moisture. The measured data at this time cannot truly reflect its performance. The comparison test shows that the specimens were cured for 168h under standard test conditions and the specimens were cured for 96h under standard test conditions, and then dried in a 40°C Drying Oven for 48h, and the tensile performance test was carried out respectively. The test data were quite different. Compared with the former maintenance method, the tensile strength can be increased by about 50%, while the elongation at break can be reduced by about 100%. Therefore, when inspecting these two types of coatings, inspectors should strictly follow the requirements of the corresponding standards for coating film maintenance, and should not be confused with the maintenance methods of polyurethane waterproof coatings, otherwise it will cause misjudgment of the results.

2 Matters needing attention in the tensile performance test of the test piece after film formation

Tensile properties refer to the tensile strength and elongation at break of the material under standard test conditions and after heat, alkali, and ultraviolet treatment. This item is an important performance index to measure the quality of waterproof coatings, and it is also one of the important performances of waterproof coatings. The following aspects should be paid attention to in the tensile performance test.

2.1 Stretching speed

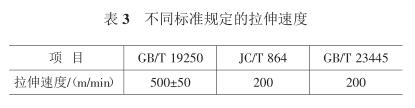

The stretching speeds stipulated by different standards are shown in Table 3. The size of the tensile speed directly affects the test results of the tensile properties of waterproof coatings: as the tensile speed increases, the tensile strength increases and the elongation at break decreases; on the contrary, the tensile speed decreases, the tensile strength decreases, and the elongation at break decreases Increase. Therefore, inspectors should conduct tensile tests according to different products and in strict accordance with the tensile speed specified in the product standard, and should not be confused, otherwise it will cause misjudgment of the results.

2.2 Measurement of thickness

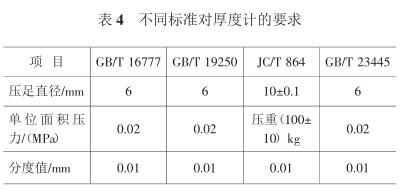

GB/T16777-2008 stipulates: Use a Thickness Gauge to measure the thickness values of three points in the middle and at both ends of the test piece marking line, and take the arithmetic mean value as the thickness of the test piece, instead of only measuring the thickness value of one point to calculate the tensile strength. Strength; In addition, different paint standards have different regulations on Thickness Gauges (Table 4), which should be paid special attention to by inspectors during inspection.

2.3 Specimen Processing Sequence

GB/T16777-2008 stipulates: before heat, acid, alkali, salt, water, ultraviolet, artificial weathering treatment, the size and shape of the test piece shall be a rectangular test piece of 120mm×25mm, and then cut into conforming GB/T528 - 1998 "Determination of Tensile Stress-Strain Properties of Vulcanized Rubber or Thermoplastic Rubber" dumbbell type I test piece. The reason is that the cross-section of the coating film is in the shape of open cells after cutting. The width of the test piece before treatment is 25mm, while the effective width of the dumbbell-shaped test piece is only 6mm. Treating first and then cutting can reduce the penetration of liquid from the cells on the cross-section to the inside. , because the coating film is a closed overall structure in practical applications, which can be closer to the actual situation. In addition, the specimen will expand slightly after treatment, so the specimen should be cut into long strips for treatment first, and then cut into dumbbell-shaped specimens to maintain the accuracy and stability of the specimen size.

In addition, for polymer cement-based waterproof coatings and polymer emulsion building waterproof coatings, the specimens still have to absorb a certain amount of water after aqueous solution treatment, so the specimens are taken out from the solution, and after cleaning and drying, the polymer cement-based waterproof coatings It must also be dried in a Drying Oven at (60±2)°C for 18 hours to remove residual moisture. After taking it out, place it in a desiccator to cool to room temperature, and then cut it into dumbbell-shaped test pieces; Dry in a Drying Oven at (60±2)°C for 6 hours, take it out and cure it under standard test conditions for (18±2) hours before cutting it into dumbbell-shaped specimens to ensure the accuracy and authenticity of the test data.

3 Epilogue

This paper analyzes several issues that should be paid attention to in the performance testing of waterproof coatings, including the laboratory environmental conditions during the film formation process, the number of times the coating film is brushed, the method of stirring and curing, and the tensile speed, thickness measurement and Specimen processing sequence, etc. In order to facilitate the laboratory operation and make the test data fair and comparable, the laboratory environment conditions should be relatively unified when the standard is formulated and revised, and details such as the number of times the coating film is applied in stages, the stirring system and the curing system should be clearly stipulated. As a testing worker, he should strictly implement, correctly understand and use the test methods stipulated in the corresponding standards in his work, and adopt a rigorous and scientific testing attitude to make the test result data fair and reliable.

- 1What equipment do you need for Coating testing? This article will help you summarize

- 2Labeling paint laboratory test plan

- 3Characteristics of Coating Analysis and Detection

- 4Coating analysis and detection commonly used technical indicators

- 5Characteristics of Coating Analysis and Detection

- 6Content of Coating Analysis and Detection

- 7Significance of Coating Analysis Testing

- 8Coating Testing Instruments Popular Products Atlas

- 9One article includes Coating testing items, instruments, and standards (all)