How to Calculate Coating Dosage

When the paint is adjusted to the construction viscosity, if it is placed for a long time, the pigment will coagulate and settle, resulting in inconsistent color or gloss decline of the coating film; for quick-drying paint, a large amount of solvent volatilization during the placement process will cause the viscosity to increase, resulting in poor spray atomization ;For the two-component residual material, it will be gelled and scrapped after the use time is exceeded. In order to avoid these phenomena, the amount of paint to be thinned is declared as being used up on the shift, and the longest is not more than 3 days, so the amount of paint needs to be estimated , including calculation methods, statistical methods and actual measurement methods, expressed in terms of consumption per unit area.

(1) Calculation method to calculate the amount of paint required

According to the parameters such as the thickness, density, non-volatile content of paint and paint utilization rate of each layer of paint film, the paint consumption per unit area of each layer of paint film can be obtained according to formula (8-1).

q c =δρ F /(eS 0 )

formula,

q c represents the consumption of original paint per unit area, g/㎡

δ is the coating thickness, μm

ρ F is the coating film density, g/㎡

e represents the coating utilization rate of each coating method, %

S 0 represents the solid content of the original paint, %

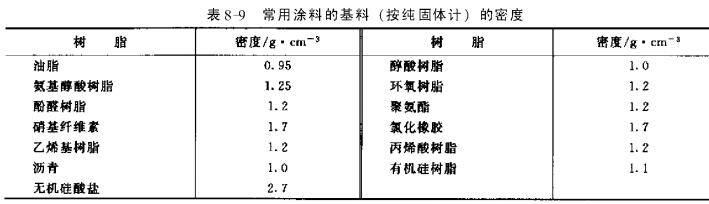

Of course, if the paint is a varnish, the film density can be approximated by the following resin density.

Compared with the color paint, the density of the coating film can be calculated from the ratio of pigment to base, and the density of resin and pigment.

ρ F =(1+PB)/(1/ ρ B +PB/ ρ p )

Among them, PB represents the pigment-base ratio, ρ B represents the density of the base material, and ρ p is the density of the pigment and filler.

For more knowledge about how to calculate the amount of paint, users are suggested to read "Painting Process and Equipment".