Pressure sensitive adhesive Viscosity test and test instrument introduction

Viscosity is a physical quantity that describes the frictional force existing between two fluid layers inside a fluid, and this frictional force increases with the increase of the relative motion speed between the two fluid layers. When the two layers of fluid with a distance of 1cm and an area of 1cm2 move relative to each other at a speed of 1cm/s. , when the resistance overcome is 1x10-5N, it is called l absolute viscosity unit, equal to 0.lPa·s. The viscosity here has nothing to do with the nature of motion, it depends on the physical properties of the fluid and temperature (in some cases, it is also related to pressure), usually called dynamic viscosity or absolute accuracy, also referred to as viscosity. The ratio of dynamic viscosity to density is called kinematic viscosity, and its unit is ㎡/s.

The viscosity of the adhesive directly affects its process performance. If the viscosity is too high, it is difficult to apply glue; if the viscosity is too small, in order to ensure a certain thickness of the adhesive layer, it is necessary to increase the number of times of glue application. The viscosity of the glue is also related to the wetting speed of the adherend. Glue flow and lack of glue are often caused by the viscosity, and both will affect the bonding strength. Therefore, the viscosity of the adhesive is an important indicator for evaluating the quality of the adhesive. Viscosity test conditions, especially temperature, have a great influence on viscosity value and need to be strictly controlled.

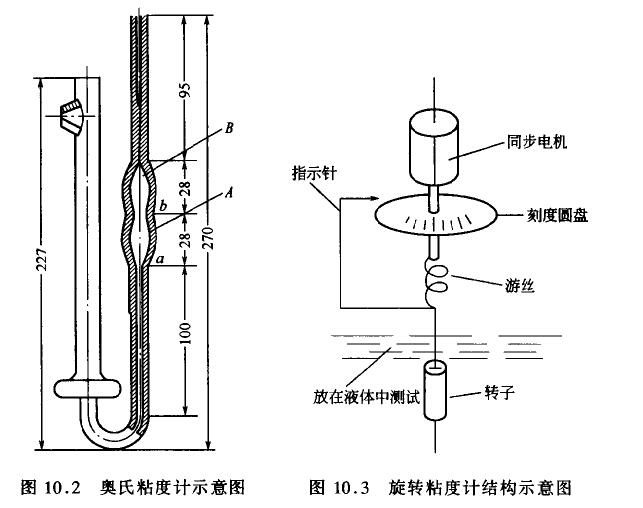

The instruments for measuring viscosity in the adhesive industry include Ostwald viscometer, falling ball viscometer, Tu-1 viscometer, Tu-4 viscometer, Rotational Viscometer, etc. Ostwald viscometers, Tu-1 viscometers, Tu-4 viscometers, etc. are used for adhesives with low viscosity. It takes too long to measure high-viscosity adhesives with such viscometers, but Rotational Viscometers have no such limitations. Therefore, internationally, the United States, Japan, France, etc. all use Rotational Viscometers to measure the viscosity of adhesives, and have testing standards. Our country also has the national standard GD2794-81 «Adhesive Viscosity Test Method - Rotational Viscometer Method». Here we only introduce two viscometers commonly used in pressure-sensitive adhesives—Oswald viscometer and Rotational Viscometer.

The structure of the rotary viscometer is shown in Figure 10.3: the synchronous motor rotates stably at a certain speed, drives the dial disk, and then drives the rotor through the hairspring and the rotating shaft. If the rotor is not affected by resistance, the hairspring will rotate at the same speed as the dial without twisting; on the contrary, if the rotor is immersed in the liquid and subjected to viscous resistance, the hairspring will generate torque to make it compete with the viscous resistance and reach equilibrium . At this time, the pointer connected with the hairspring indicates a certain reading on the dial.

This method has a wide range of applications, such as Nl:)J-1 type Rotational Viscometer, the measurement range can be from 10-2 to 102Pa s; with Brookfield conformity meter, the measurement range can be from 0 to 8xl03Pa s. When measuring, first install the instrument horizontally on the fixed support, then select the appropriate rotor and speed according to the viscosity of the sample, so that the reading is within the range of 15%~85% of the dial, and finally at the specified temperature of the sample , turn on the power, and read the indicated value when rotating for lmin (±2s) (when measuring a high-viscosity sample, read the reading when rotating for 2min).